Unraveling Metabolic Pathways: A Comprehensive Guide to 13C Kinetic Flux Profiling (KFP) Protocol

This article provides a detailed, step-by-step guide to the 13C Kinetic Flux Profiling (KFP) protocol for researchers and drug development professionals.

Unraveling Metabolic Pathways: A Comprehensive Guide to 13C Kinetic Flux Profiling (KFP) Protocol

Abstract

This article provides a detailed, step-by-step guide to the 13C Kinetic Flux Profiling (KFP) protocol for researchers and drug development professionals. Covering foundational principles, methodological execution, and advanced applications, it explores how KFP quantifies intracellular metabolic fluxes using stable isotope tracers. We detail experimental design, data acquisition via mass spectrometry, computational flux analysis, and troubleshooting common pitfalls. The content validates KFP against other flux analysis methods and highlights its crucial role in identifying metabolic vulnerabilities in disease and for evaluating drug mechanisms of action in preclinical research.

What is 13C Kinetic Flux Profiling? Core Principles and Scientific Rationale

1. Introduction: Thesis Context and Rationale

This application note is framed within a broader thesis research program focused on advancing the 13C Kinetic Flux Profiling (KFP) protocol. While classical steady-state 13C Metabolic Flux Analysis (MFA) provides a snapshot of net fluxes through metabolic networks at isotopic equilibrium, it lacks temporal resolution for dynamic processes. KFP addresses this by quantifying the time-dependent labeling of metabolites following the introduction of a 13C tracer, thereby enabling the determination of absolute intracellular flux rates (in µmol/gDW/min) and pool sizes. This protocol is critical for research in systems biology, cancer metabolism, and drug development, where understanding metabolic adaptation and target engagement is paramount.

2. Core Principles of Kinetic Flux Profiling

KFP utilizes dynamic 13C labeling data, typically from LC-MS measurements, to fit parameters of an ordinary differential equation (ODE) model representing the metabolic network. The fitted parameters are the unidirectional fluxes (V) and metabolite pool sizes (Q). This contrasts with steady-state MFA, which solves for net fluxes at isotopic steady-state. KFP's requirement for precise time-series data and sophisticated computational fitting presents both a challenge and a source of richer biological insight.

3. Application Notes: Key Insights from Recent Studies

Recent applications of KFP have elucidated rapid metabolic rewiring in response to stimuli. The following table summarizes quantitative findings from key studies illustrative of the KFP approach.

Table 1: Summary of Quantitative Insights from Recent KFP Studies

| Biological System | Perturbation | Key Metabolic Finding via KFP | Quantified Change (Example) | Implication |

|---|---|---|---|---|

| Cultured Cancer Cells | Acute EGF stimulation | Glycolytic flux increase precedes TCA cycle change | VPFK increased by 80% within 2 minutes | Signaling-driven metabolic prioritization |

| Activated T Cells | Immune receptor engagement | Anaplerotic pyruvate carboxylase (PC) flux surge | VPC increased 5-fold within 1 hour | Supports biomass for proliferation |

| Hepatocytes | Glucagon exposure | Rapid diversion of gluconeogenic flux | VPEPCK doubled within 10 minutes | Hormonal control of metabolic routing |

| Drug-Treated Cells (Thesis Focus) | OXPHOS inhibitor (e.g., Metformin) | Compensatory glycolysis and serine biosynthesis flux | VPHGDH increased by 150% | Identifies potential drug resistance pathways |

4. Detailed Experimental Protocol: 13C-KFP in Mammalian Cells

4.1. Materials and Reagent Solutions

Table 2: The Scientist's Toolkit - Key Reagents for 13C-KFP

| Reagent / Material | Function / Explanation |

|---|---|

| U-13C-Glucose (or other tracer) | Uniformly labeled substrate to initiate labeling kinetics; defines the entry point of label. |

| Custom, Serum-Free Labeling Medium | Chemically defined medium necessary for precise control of extracellular nutrient concentrations. |

| Rapid Sampling Apparatus (e.g., Vacuum Filtration) | Enables quenching of metabolism and collection of samples at sub-second to minute intervals. |

| Pre-chilled Quenching Solution (e.g., 60% Methanol -40°C) | Instantly halts enzymatic activity to preserve metabolic state at time of sampling. |

| LC-MS/MS System with High Resolution | For accurate quantification of metabolite concentrations (via unlabeled peaks) and 13C isotopologue distributions. |

| Computational Software (e.g., INCA, Q-Flux) | Used for kinetic model construction, experimental data integration, and non-linear parameter fitting. |

4.2. Step-by-Step Protocol

Day 1: Cell Preparation

- Seed cells in appropriate dishes to reach 70-80% confluence at time of experiment.

- 24 hours prior to experiment, switch cells to custom serum-free, chemically defined medium matching the future labeling medium except for the tracer.

Day 2: Kinetic Labeling Experiment

- Pre-equilibration: Aspirate medium and wash cells twice with pre-warmed PBS. Add pre-warmed labeling medium containing natural abundance nutrients. Incubate for 60 min to establish a metabolic steady-state under experimental conditions.

- Tracer Switch & Rapid Sampling: Rapidly aspirate medium and immediately add labeling medium containing the 13C tracer (e.g., [U-13C] Glucose). Start timer.

- Sample cells at a pre-determined time series (e.g., 0, 15s, 30s, 1m, 2m, 5m, 10m, 20m, 30m, 60m).

- For adherent cells: Use rapid vacuum aspiration/quenching with cold methanol or direct scraping into quenching solvent.

- Sample Processing: Extracellular medium is also collected at each time point for exometabolite analysis. Cell pellets are extracted using a methanol/water/chloroform extraction. Extracts are centrifuged, and the aqueous phase is dried and stored at -80°C for LC-MS analysis.

Day 3-4: LC-MS Metabolomics

- Reconstitute samples in MS-compatible solvent.

- Run samples on a hydrophilic interaction liquid chromatography (HILIC) or ion-pairing LC system coupled to a high-resolution mass spectrometer.

- Acquire data in full-scan mode to quantify isotopologue distributions (M+0, M+1, M+2, … M+n) for target metabolites (e.g., glycolytic intermediates, TCA cycle acids, amino acids).

- Quantify absolute pool sizes using internal standards and calibration curves run in parallel.

Day 5-7: Computational Modeling & Flux Estimation

- Model Construction: Define a stoichiometric network model including atom transitions.

- Data Integration: Input the measured time-course data: extracellular nutrient/ byproduct rates, intracellular pool sizes (from M+0), and isotopologue fractions.

- Parameter Fitting: Use non-linear least squares optimization to fit the unknown parameters (V, Q) to the labeling kinetics data. This step minimizes the difference between model-simulated and experimentally measured isotopologue time courses.

- Statistical Analysis: Perform Monte Carlo simulations or sensitivity analysis to estimate confidence intervals for the fitted fluxes and pool sizes.

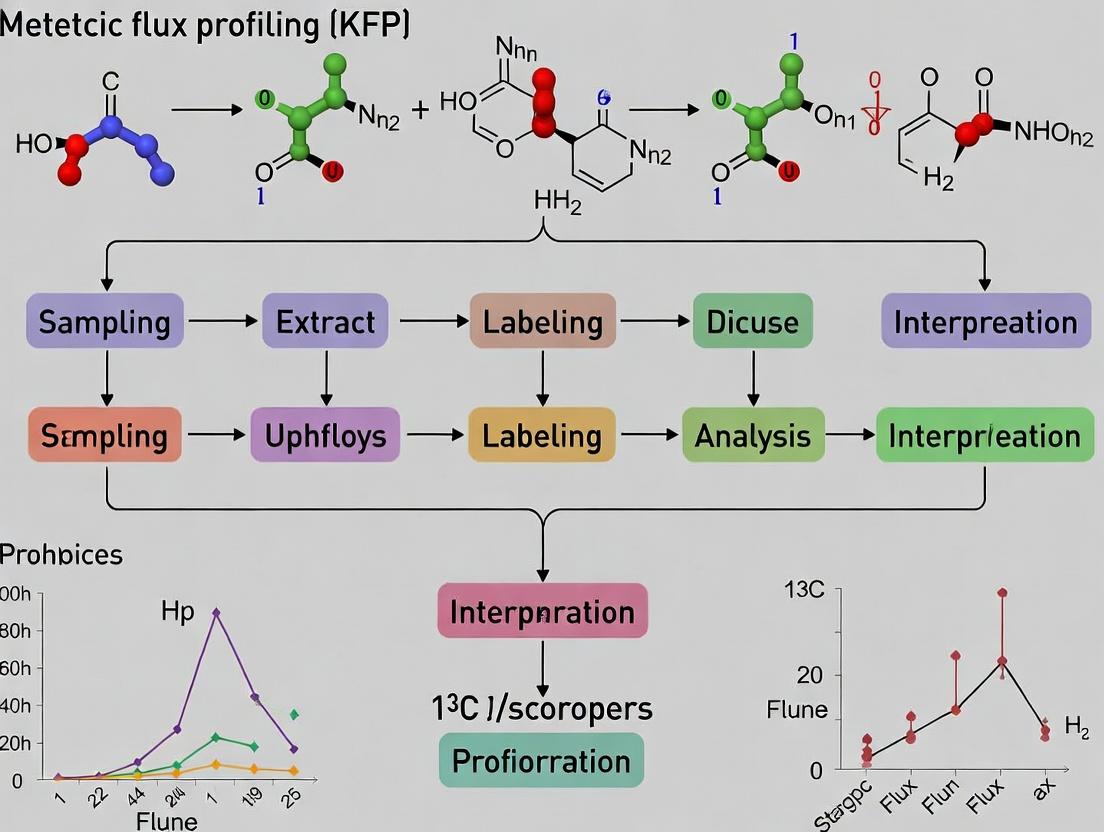

5. Visualizing the KFP Workflow and Metabolic Network

13C Kinetic Flux Profiling (KFP) Core Workflow

Simplified Network for 13C-KFP of Central Metabolism

The Central Role of 13C-Labeled Tracers in Dynamic Flux Measurement

Kinetic Flux Profiling (KFP) is a cornerstone methodology within metabolic research, enabling the quantitative, time-resolved measurement of intracellular reaction rates (fluxes). At the heart of KFP is the use of 13C-labeled tracers, which provide the temporal dimension necessary to observe pathway dynamics, rather than static snapshots. This application note details the protocols and critical considerations for implementing 13C-based KFP within a drug discovery and biomedical research context, where understanding metabolic rewiring is essential.

13C-KFP tracks the incorporation of stable isotope atoms from a labeled nutrient (e.g., [U-13C]glucose) into downstream metabolites over time. The resulting labeling patterns and kinetics are used with computational models to infer absolute metabolic fluxes.

Table 1: Common 13C-Labeled Tracers and Their Applications in KFP

| Tracer Compound | Labeling Pattern | Primary Pathway Interrogated | Typical Concentration Range | Key Measured Fluxes |

|---|---|---|---|---|

| Glucose | [U-13C] | Glycolysis, PPP, TCA Cycle | 5-25 mM (match media) | Glycolytic flux, Pyruvate dehydrogenase/ carboxylase flux |

| Glucose | [1-13C] | Pentose Phosphate Pathway (PPP) | 5-25 mM | Oxidative vs. non-oxidative PPP flux |

| Glutamine | [U-13C] | Anaplerosis, TCA Cycle, Reductive carboxylation | 2-6 mM (match media) | Glutaminolysis flux, α-KG dehydrogenase flux |

| Acetate | [U-13C] | Acetyl-CoA metabolism | 1-5 mM | Cytosolic vs. mitochondrial acetyl-CoA usage |

| 13C-Lactate | [3-13C] | Gluconeogenesis, Cori cycle | 1-10 mM | Lactate uptake, PC flux |

Table 2: Mass Spectrometry Platforms for 13C-KFP Analysis

| Platform Type | Measured Ions | Typical Time Resolution (for KFP) | Key Advantage for KFP |

|---|---|---|---|

| GC-MS (Quadrupole) | Fragmentation patterns of derivatized metabolites | 5-15 minutes | High reproducibility, extensive libraries |

| LC-MS (Q-TOF/Orbitrap) | Intact metabolite masses (M+, M+1, M+2... M+n) | 2-10 minutes | Broad coverage without derivatization, high mass accuracy |

| LC-MS/MS (TQMS) | Specific fragment ions | 3-7 minutes | Superior sensitivity for low-abundance metabolites |

Detailed Experimental Protocols

Protocol 1: Cell Culture Pulse-Chase Experiment for Central Carbon Metabolism KFP

Objective: To determine dynamic fluxes in glycolysis, TCA cycle, and associated pathways.

Materials:

- Adherent or suspension cells (e.g., cancer cell line, primary hepatocytes)

- Standard growth medium (e.g., DMEM, RPMI)

- Custom tracer medium: Identical composition but with natural glucose replaced by [U-13C]glucose.

- Phosphate-Buffered Saline (PBS), pre-warmed and isotope-free.

- Quenching solution: 60% methanol (LC-MS grade) in water, chilled to -40°C to -80°C.

- Extraction solvent: 80% methanol/water at -80°C.

- Cell scraper or equivalent.

- Centrifuge and vortexer.

- SpeedVac concentrator.

- GC-MS or LC-MS autosampler vials.

Procedure:

- Culture & Preparation: Grow cells to desired confluence (typically 70-80%) in standard medium. Use biological replicates (n≥3).

- Medium Exchange: Rapidly aspirate standard medium. Wash cells twice quickly with pre-warmed PBS to remove natural nutrient traces.

- Pulse Initiation (t=0): Immediately add pre-warmed tracer medium containing [U-13C]glucose.

- Time-Course Sampling: At defined time points (e.g., 0, 15s, 30s, 1min, 2min, 5min, 10min, 30min, 60min): a. Rapidly aspirate tracer medium. b. Immediately add chilled quenching solution (e.g., 1 mL for a 6-well plate well). Place plate on dry ice or at -80°C.

- Metabolite Extraction: Scrape cells in the quenching solution. Transfer cell suspension to a pre-chilled microcentrifuge tube. a. Vortex vigorously for 30 seconds. b. Centrifuge at max speed (>15,000 g) for 10 minutes at 4°C. c. Transfer supernatant to a new tube. d. Dry the supernatant in a SpeedVac concentrator (no heat).

- Sample Analysis: Resuspend dried metabolites in appropriate solvent for MS analysis (e.g., water for LC-MS, methoxyamine/pyridine for GC-MS). Analyze via GC-MS or LC-MS.

Protocol 2: LC-MS/MS Method for Key 13C-Labeled Metabolite Quantification

Objective: To separate and detect the mass isotopomer distribution (MID) of central carbon metabolites.

Chromatography (HILIC Method Example):

- Column: SeQuant ZIC-pHILIC (5 µm, 2.1 x 150 mm)

- Mobile Phase A: 20 mM ammonium carbonate, 0.1% ammonium hydroxide in water

- Mobile Phase B: Acetonitrile

- Gradient: 80% B to 20% B over 20 min, hold 5 min, re-equilibrate.

- Flow Rate: 0.15 mL/min

- Column Temperature: 40°C

- Injection Volume: 5-10 µL

Mass Spectrometry (Q-TOF Example):

- Ionization: Electrospray Ionization (ESI), negative mode for organic acids, positive for amino acids.

- Scan Range: m/z 70-1000

- Source Conditions: Gas Temp 250°C, Drying Gas 10 L/min, Nebulizer 30 psi.

- Data Acquisition: Full scan mode for accurate mass. Data-dependent MS/MS for verification.

- Data Analysis: Use software (e.g., Agilent MassHunter, XCMS, or custom MATLAB/Python scripts) to extract chromatographic peaks and calculate MIDs for metabolites of interest (e.g., glucose-6P, lactate, citrate, malate, aspartate).

Visualization of KFP Concepts and Workflows

Title: KFP Experimental and Computational Workflow

Title: 13C Flow from Glucose to Early TCA Cycle

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for 13C-KFP

| Item | Function/Benefit in KFP | Example Product/Catalog Number (Informational) |

|---|---|---|

| [U-13C]Glucose | Uniformly labeled tracer for comprehensive mapping of carbon fate through glycolysis, PPP, and TCA cycle. Essential for mass balance. | CLM-1396 (Cambridge Isotope Labs) |

| [U-13C]Glutamine | Critical tracer for analyzing glutaminolysis, anaplerotic flux into TCA cycle, and reductive carboxylation in conditions like hypoxia. | CLM-1822 (Cambridge Isotope Labs) |

| Isotope-Free Base Medium | Custom formulated medium lacking the target nutrient (e.g., glucose- or glutamine-free DMEM) for precise tracer medium preparation. | Various (e.g., US Biological, Sigma) |

| Pre-chilled 60% Methanol | Quenching solution that rapidly halts metabolic activity, preserving the in vivo labeling state at the moment of sampling. | Prepared in-house (LC-MS grade) |

| Derivatization Reagent (for GC-MS) | Converts polar metabolites to volatile derivatives (e.g., MOX-TBDMS). Enables gas chromatography separation. | N-Methyl-N-(tert-butyldimethylsilyl)trifluoroacetamide (MTBSTFA) |

| HILIC Chromatography Column | Separates highly polar, water-soluble metabolites (sugar phosphates, organic acids) for LC-MS analysis. | SeQuant ZIC-pHILIC (MilliporeSigma) |

| Internal Standard Mix (13C or 15N labeled) | Corrects for variation in extraction efficiency and instrument response during MS analysis. | MSK-CUS-INDY (Cambridge Isotope Labs) |

| Flux Analysis Software | Performs computational modeling to convert time-course MID data into quantitative flux maps. | INCA, IsoCor, OpenFLUX, 13C-FLUX2 |

Application Notes

13C Kinetic Flux Profiling (KFP) has emerged as a pivotal methodology for quantifying metabolic flux dynamics in living cells. Within the broader thesis on KFP protocol research, this approach directly addresses the core biological question of how intracellular pathway activity is reprogrammed in response to therapeutic intervention, thereby predicting and explaining drug response. Recent advances have demonstrated its utility from basic biology to translational drug development.

Connecting Flux to Phenotype: A primary application is the quantification of flux rewiring in cancer models upon treatment with targeted therapies (e.g., kinase inhibitors) or chemotherapies. KFP can reveal compensatory metabolic pathways that enable cell survival, identifying potential drug targets for combination therapies. For instance, increased glutaminase flux is a known resistance mechanism to PI3K/mTOR inhibitors.

Pharmacodynamic Assessment: KFP serves as a powerful pharmacodynamic (PD) biomarker tool. By tracing 13C-labeled nutrients (e.g., [U-13C]-glucose, [U-13C]-glutamine) into downstream metabolites, researchers can measure the in vivo modulation of specific pathway activities (like glycolysis, TCA cycle, or pentose phosphate pathway) within hours of drug administration, far earlier than tumor volume changes.

Predictive Biomarker Discovery: Pre-treatment fluxomic profiles can classify tumors based on their metabolic dependencies. Tumors reliant on oxidative phosphorylation (OxPhos) may be intrinsically resistant to glycolytic inhibitors but sensitive to mitochondrial poisons. KFP enables the functional annotation of these states beyond genomic signatures.

Quantitative Data Summary:

Table 1: Representative KFP-Derived Flux Changes in Cancer Cell Lines Upon Drug Treatment

| Drug Class (Example) | Target Pathway | Key Flux Alteration (Measured by KFP) | Fold-Change Range | Implication for Response |

|---|---|---|---|---|

| PI3K/mTOR Inhibitor (e.g., Pictilisib) | Glycolysis, PPP | ↓ Glycolytic flux to lactate; ↑ OxPhos; ↑ Pentose Phosphate Pathway flux | Glycolysis: 0.3-0.7x; PPP: 1.5-3.0x | Compensatory NADPH production; Resistance via metabolic plasticity |

| IDH1 Inhibitor (e.g., Ivosidenib) | TCA Cycle | ↓ D-2-hydroxyglutarate production; ↑ glutaminolysis | D2HG: <0.1x; Gln Anaplerosis: 1.8-2.5x | On-target efficacy; Possible adaptive fueling |

| Chemotherapy (e.g., Doxorubicin) | Nucleotide Synthesis | ↑ Pyrimidine de novo synthesis flux from glucose | 2.0-4.0x | Increased demand for DNA repair; Target for sensitization |

| Glutaminase Inhibitor (e.g., CB-839) | Amino Acid Metabolism | ↓ Malate from glutamine; ↑ glucose-derived anaplerosis | Gln→Malate: 0.2-0.5x | Efficacy in glutamine-addicted models; Resistance via glucose fueling |

Table 2: Essential 13C-Labeled Tracers for Drug Response Studies

| Tracer | Primary Pathways Probed | Typical Concentration | Key Drug Response Questions |

|---|---|---|---|

| [U-13C]-Glucose | Glycolysis, PPP, TCA Cycle, Serine Synthesis | 5-25 mM (culture media) | How does drug X affect glycolytic commitment vs. mitochondrial oxidation? |

| [U-13C]-Glutamine | Glutaminolysis, TCA Cycle (anaplerosis), Redox balance | 2-4 mM | Does the drug impair glutamine-fueled biomass/energy production? |

| [1,2-13C]-Glucose | PPP vs. Glycolysis partitioning | 5-25 mM | Is the oxidative PPP induced as a survival mechanism? |

| [U-13C]-Palmitate (with BSA) | Fatty Acid Oxidation (FAO) | 100-200 µM | Does therapy induce a dependency on mitochondrial FAO? |

Detailed Protocols

Protocol 1: KFP Workflow forIn VitroDrug Response Profiling

Objective: To quantify acute changes in central carbon metabolism flux following drug treatment in adherent cancer cell lines.

I. Materials & Cell Preparation

- Cells in mid-log phase.

- Drug of interest and vehicle control.

- Customized tracer media: DMEM-based, lacking glucose and glutamine, supplemented with dialyzed FBS, 10 mM [U-13C]-Glucose, and 4 mM [U-13C]-Glutamine.

- Quenching solution: 60% cold aqueous methanol (-40°C).

- LC-MS system with appropriate columns (e.g., HILIC for polar metabolites).

II. Procedure

- Seed & Treat: Seed cells at 70% confluence. After 24h, treat with drug or vehicle for the desired pharmacodynamic window (e.g., 2, 6, 24h).

- Tracer Pulse: At the end of drug treatment, quickly aspirate media and replace with pre-warmed 13C tracer media. Incubate for a precisely timed pulse (typically 15 min to 2 h, optimized for linear incorporation).

- Rapid Metabolite Extraction:

- Aspirate tracer media and immediately wash plates with 5 mL of ice-cold 0.9% NaCl.

- Add 1 mL of quenching solution, then scrape cells on dry ice.

- Transfer extract to a cold tube, vortex, and incubate at -40°C for 30 min.

- Centrifuge at 16,000 x g for 15 min at -9°C. Transfer supernatant to a new tube.

- Dry under a gentle stream of nitrogen or in a speed vacuum.

- LC-MS Sample Prep & Analysis:

- Reconstitute dried extracts in 100 µL of LC-MS compatible solvent (e.g., water:acetonitrile, 1:1).

- Centrifuge and transfer to MS vials.

- Run on a HILIC column coupled to a high-resolution mass spectrometer.

- Acquire data in negative/positive ion switching mode to cover a broad metabolome.

- Data Processing: Use software (e.g., El-MAVEN, XCMS) to integrate peaks. Correct for natural isotope abundance and calculate 13C isotopologue distributions (MIDs) for key metabolites.

Protocol 2:In VivoFlux Analysis of Tumor Drug Response

Objective: To measure tumor metabolic flux in situ following drug administration in a mouse xenograft model.

I. Materials

- Tumor-bearing mice (subcutaneous or orthotopic).

- Sterile [U-13C]-Glucose solution in PBS (e.g., 1.5 g/kg body weight).

- Infusion pump or materials for bolus injection.

- Drug or vehicle control.

- Liquid nitrogen or clamp freezer for tissue fixation.

II. Procedure

- Drug Treatment: Administer drug or vehicle to mice at therapeutically relevant dose and schedule.

- 13C-Glucose Infusion: At the pharmacodynamic peak (e.g., 2h post-drug), anesthetize mouse. Perform a tail-vein bolus injection or start a primed, constant infusion of [U-13C]-glucose over a defined period (e.g., 10-30 min).

- Rapid Tissue Collection: At the end of infusion, euthanize the animal and immediately excise the tumor. Submerge tissue in liquid nitrogen within 5-10 seconds. Store at -80°C.

- Tissue Metabolite Extraction:

- Weigh ~50 mg of frozen tissue and homogenize in 1 mL of 80% cold methanol using a bead mill or homogenizer on dry ice.

- Follow similar quenching, centrifugation, and drying steps as in Protocol 1.

- LC-MS Analysis & Modeling: Analyze as in Protocol 1. Use the 13C MID data in computational flux models (e.g., INCA, TFLUX) constrained by the in vivo infusion regimen to estimate absolute metabolic fluxes.

Diagrams

Diagram 1: KFP Drug Response Experimental Workflow

Diagram 2: Core Metabolic Pathways Probed by KFP in Drug Studies

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for KFP Drug Response Studies

| Item | Function in Experiment | Key Considerations |

|---|---|---|

| 13C-Labeled Tracers ([U-13C]-Glucose, etc.) | Source of isotopic label to track atom fate through metabolic networks. | Chemical purity >98%; Use cell culture-tested, sterile filtered solutions. |

| Tracer Media Base (Glucose/Glutamine-Free DMEM) | Provides unlabeled nutrients, vitamins, salts; allows precise control of labeled nutrient concentration. | Must be supplemented with dialyzed serum to remove unlabeled small molecules. |

| Dialyzed Fetal Bovine Serum (FBS) | Provides essential proteins/growth factors without confounding unlabeled nutrients (e.g., glucose, amino acids). | Essential for reducing background in tracer experiments. |

| Cold Metabolite Quenching Solvent (60% Methanol, -40°C) | Instantly halts enzymatic activity to "snapshot" the metabolic state at the moment of sampling. | Must be ice-cold; often contains internal standards for extraction control. |

| HILIC Chromatography Column (e.g., ZIC-pHILIC) | Separates highly polar, charged central carbon metabolites (sugars, organic acids, CoAs) for MS detection. | Critical for resolving isomers (e.g., glucose-6-P vs. fructose-6-P). |

| High-Resolution Mass Spectrometer (Q-Exactive, TripleTOF) | Detects and quantifies metabolites with high mass accuracy to distinguish 13C isotopologues. | Enables untargeted profiling alongside targeted flux analysis. |

| Flux Analysis Software (INCA, IsoCor, TFLUX) | Computational platform to fit 13C MID data to metabolic network models and calculate reaction fluxes (rates). | Requires precise network definition and experimental input constraints. |

| Cryogenic Tissue Preservation Tools (Liquid N2, Clamp Freezer) | For in vivo studies: instantaneously fixes metabolic state in situ upon tissue collection. | Speed is critical to prevent post-mortem metabolic changes. |

This document outlines the essential prerequisites for implementing ¹³C Kinetic Flux Profiling (KFP), a powerful methodology for quantifying metabolic flux dynamics. This protocol is framed within a broader thesis research context aiming to elucidate the metabolic reprogramming induced by oncogenic signaling or therapeutic intervention in cancer models. Successful execution requires integrated capabilities in analytical biochemistry, mammalian cell culture, and computational data analysis.

Laboratory Equipment

The experimental workflow demands specialized instrumentation for precise tracer experiments, metabolite extraction, and analytical separation/detection.

Table 1: Essential Laboratory Equipment

| Equipment Category | Specific Instrument | Critical Specifications | Role in 13C-KFP |

|---|---|---|---|

| Cell Culture | CO₂ Incubator | Stable temperature (±0.2°C), CO₂ control (±0.1%), humidity control | Maintains physiological conditions for consistent cell growth during tracer pulsing. |

| Quenching & Extraction | Rapid Quenching System (e.g., -40°C methanol bath) | Achieves < 5-second quenching | Instantaneously halts metabolism to preserve in vivo labeling states. |

| Sample Preparation | Cryogenic Mill or Sonicator | Efficient lysis at -20°C or below | Disrupts cells in extraction solvent for complete metabolite recovery. |

| Analytical Core | Liquid Chromatography (LC) System | Ultra-High Performance (UHPLC), stable gradients (<2% RSD) | High-resolution separation of polar metabolites (e.g., glycolytic/TCA intermediates). |

| Analytical Core | Tandem Mass Spectrometer (MS) | High-resolution (≥ 60,000 @ m/z 200), fast polarity switching, MS/MS capability | Detects and quantifies mass isotopologue distributions (MIDs) of target metabolites. |

| Ancillary | Centrifuges (refrigerated) | Capable of 15,000 x g at -9°C | Pellet debris during metabolite extraction. |

| Ancillary | Analytical Balances | 0.01 mg sensitivity | Precise weighing of internal standards and reagents. |

Computational Tools & Software

Data analysis is a multi-step process requiring specialized software for MID deconvolution, flux modeling, and statistical evaluation.

Table 2: Essential Computational Tools

| Tool Category | Software/Package | Primary Function | Key Output |

|---|---|---|---|

| Raw Data Processing | Vendor Software (e.g., XCalibur, MassHunter) | LC-MS data acquisition and initial peak integration. | Raw peak areas for mass isotopologues. |

| MID Correction & Analysis | IsoCor2, Metran | Corrects for natural isotope abundance and instrument noise. Calculates mean enrichment (M+0, M+1, ... M+n) fractions. | Natural abundance-corrected MIDs. |

| Flux Modeling & Simulation | INCA (Isotopomer Network Compartmental Analysis), COBRApy | Mathematical modeling of metabolic networks to fit ¹³C-labeling time courses and estimate in vivo reaction rates (fluxes). | Estimated net and exchange fluxes, confidence intervals. |

| Statistical & Data Visualization | R (with ggplot2, pheatmap), Python (Pandas, NumPy, Matplotlib/Seaborn) | Statistical testing (e.g., t-tests on flux estimates), generation of heatmaps, time-course plots, and pathway diagrams. | Publication-quality figures, p-values for differential fluxes. |

| Pathway Visualization | PathVisio, Escher | Graphical representation of metabolic networks and mapping of estimated flux values onto pathways. | Intuitive flux maps. |

Experimental Protocol: 13C-KFP in Adherent Cancer Cell Lines

Protocol: Tracer Experiment and Metabolite Extraction

Objective: To introduce a ¹³C-labeled substrate (e.g., [U-¹³C₆]-Glucose) and trace its incorporation into intracellular metabolites over a finely resolved time course.

Materials:

- Cells of interest (e.g., A549 lung carcinoma cells).

- Growth medium (appropriate formulation, e.g., DMEM).

- Dialyzed Fetal Bovine Serum (dFBS).

- Tracer Substrate: 100 mM [U-¹³C₆]-Glucose solution in PBS, sterile-filtered.

- Quenching/Extraction Solvent: 80% (v/v) HPLC-grade methanol in water, chilled to -40°C.

- Internal Standard Mix: Stable isotope-labeled metabolites (e.g., ¹³C₁₅-ATP, ²H₄-Succinate) in extraction solvent.

Procedure:

- Culture & Preparation: Seed cells in 6-well plates to reach 70-80% confluence at experiment start. 24h prior to experiment, switch cells to medium formulated with dFBS and physiological glucose (e.g., 5.5 mM).

- Tracer Pulse: a. Prepare "time-zero" plates: Aspirate medium, quickly add 1 mL of -40°C quenching solvent, and place plate on dry ice. This is t=0. b. For time points (e.g., 0.25, 0.5, 1, 2, 5, 10, 20 min): Rapidly aspirate medium from a well and immediately add 1 mL of pre-warmed medium containing 11 mM [U-¹³C₆]-Glucose (final conc.: 5.5 mM tracer + 5.5 mM natural abundance glucose). c. Incubate plate for the exact duration.

- Quenching & Extraction: a. At the precise time point, aspirate tracer medium and immediately add 1 mL of -40°C 80% methanol. b. Add a pre-determined volume of internal standard mix. c. Scrape cells on dry ice or at -20°C and transfer extract to a pre-chilled microcentrifuge tube. d. Vortex for 30s, then incubate at -20°C for 1 hour. e. Centrifuge at 15,000 x g, -9°C for 15 min. f. Transfer supernatant (soluble metabolite fraction) to a fresh tube. Dry under a gentle stream of nitrogen gas. g. Store dried pellets at -80°C until LC-MS analysis.

- LC-MS Analysis: Reconstitute pellets in appropriate solvent (e.g., 100 µL water:acetonitrile, 98:2). Analyze using a HILIC-UHPLC coupled to a high-resolution Q-Exactive orbitrap MS. Use negative and positive polarity switching.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Key Reagents for 13C-KFP

| Reagent | Function & Importance |

|---|---|

| [U-¹³C₆]-Glucose | The primary tracer. Uniform labeling allows tracing of carbon atoms through glycolysis, PPP, and TCA cycle. Essential for calculating fractional enrichment. |

| Dialyzed Fetal Bovine Serum (dFBS) | Serum processed to remove low-molecular-weight metabolites (e.g., glucose, glutamine). Prevents dilution of the administered tracer, ensuring accurate labeling kinetics. |

| Stable Isotope-Labeled Internal Standards (e.g., ¹³C₁₅-ATP, ²H₄-Succinate) | Added during extraction to correct for variations in sample processing, ionization efficiency, and instrument drift. Crucial for accurate absolute quantitation. |

| HPLC-grade Methanol & Water | Used in quenching/extraction. High purity minimizes background chemical noise during LC-MS analysis, improving signal-to-noise for target metabolites. |

| HILIC UHPLC Column (e.g., BEH Amide) | Stationary phase for separating highly polar, hydrophilic central carbon metabolites that are challenging to retain on reverse-phase columns. |

Required Expertise

- Mammalian Cell Culture (Aseptic Technique): Ability to maintain consistent, contamination-free cultures.

- Analytical Chemistry: Understanding of LC-MS principles, operation, and basic troubleshooting.

- Metabolomics Data Analysis: Proficiency in processing raw MS data, MID correction, and interpreting isotopologue patterns.

- Mathematical Modeling: Comfort with basic principles of kinetic modeling, differential equations, and using software like INCA.

- Programming/Scripting: Basic skills in R or Python for data wrangling, statistical analysis, and visualization.

Visualizations

13C-KFP Core Experimental Workflow

TCA Cycle Labeling from U-13C6 Glucose

Executing the 13C KFP Protocol: A Step-by-Step Experimental and Computational Workflow

Within the broader thesis on developing a robust and standardized 13C Kinetic Flux Profiling (KFP) protocol, Phase 1 is foundational. This phase defines the critical parameters that determine the success of subsequent metabolic flux analysis. Proper selection of isotopic tracers, biological model systems, and sampling time points is essential for capturing dynamic flux rewiring in response to perturbations such as drug treatment.

Tracer Selection and Rationale

The choice of 13C-labeled tracer dictates which metabolic pathways can be interrogated. The tracer should enter metabolism at a point upstream of the pathways of interest. Table 1 summarizes commonly used tracers and their primary applications.

Table 1: Common 13C Tracers for Kinetic Flux Profiling in Mammalian Systems

| Tracer | Common Labeling Pattern | Primary Pathways Illuminated | Key Considerations |

|---|---|---|---|

| [1,2-13C]Glucose | U-13C, 1-13C, or 2-13C | Glycolysis, Pentose Phosphate Pathway (PPP), TCA Cycle via Pyruvate | Standard for central carbon metabolism. U-13C provides most labeling information. |

| [U-13C]Glutamine | Uniformly Labeled (U-13C) | Glutaminolysis, TCA Cycle (anaplerosis via α-KG), Nucleotide synthesis | Critical for studying cancer and rapidly proliferating cells. |

| [U-13C]Palmitate | Uniformly Labeled (U-13C) | Fatty Acid Oxidation (β-oxidation), TCA Cycle | Used for probing lipid metabolism. Requires albumin conjugation for delivery. |

| 13C-Lactate | 3-13C or U-13C | TCA Cycle (via pyruvate), Cori cycle, gluconeogenesis | Gaining importance in tumor metabolism and microenvironment studies. |

| [1-13C]Pyruvate | 1-13C | TCA Cycle entry, lactate production, alanine synthesis | Rapidly metabolized; useful for very short time-course experiments. |

Cell System Selection

The biological model must be chosen based on physiological relevance, growth characteristics, and experimental feasibility.

Table 2: Considerations for Selecting Cell Systems for 13C-KFP

| System Type | Examples | Advantages | Disadvantages |

|---|---|---|---|

| Immortalized Cell Lines | HEK293, HeLa, MCF-7, A549 | High reproducibility, easy culture, readily available. | May have adapted/aberrant metabolism. |

| Primary Cells | Human PBMCs, hepatocytes, fibroblasts | More physiologically relevant. | Limited lifespan, donor variability, can be difficult to culture. |

| Cancer Stem Cells (CSCs) | Patient-derived spheroid cultures | Highly relevant for drug development in oncology. | Technically challenging, heterogeneous. |

| Engineered Cells | KO/KD of specific metabolic enzymes | Enables direct causal links between gene function and flux. | Requires significant time and resources to generate. |

Time-Course Design

Sampling at multiple time points is crucial to distinguish between labeling equilibrium (isotopic steady-state) and metabolic steady-state. Time points must capture the kinetics of label incorporation into metabolites of interest.

Protocol 4.1: Determining an Initial Time-Course

- Preliminary Experiment: Conduct a rapid, dense time-course experiment.

- Cell Preparation: Seed cells in 6-well plates. At ~80% confluency, replace media with tracer-containing media (e.g., 11 mM [U-13C]Glucose in DMEM base).

- Sampling: Quench metabolism at intervals (e.g., 0, 15 min, 30 min, 1h, 2h, 4h, 8h, 12h, 24h) using cold (-20°C) 80% methanol (v/v) in water.

- Analysis: Use LC-MS to track 13C enrichment in key metabolites (e.g., lactate, alanine, citrate, succinate, malate, aspartate).

- Optimization: Plot fractional enrichment vs. time. Design the definitive experiment to capture the exponential rise to plateau for intermediate pools.

Table 3: Suggested Initial Time-Course Ranges for Common Tracers

| Tracer | Recommended Initial Range | Fast-Labeling Metabolite (Check) | Slow-Labeling Metabolite (Check) |

|---|---|---|---|

| [U-13C]Glucose | 15 min to 24 hours | Lactate, Alanine (hours) | Aspartate, Citrate (tens of hours) |

| [U-13C]Glutamine | 15 min to 12 hours | Glutamate (minutes) | Citrate, Aspartate (hours) |

| 13C-Lactate | 5 min to 6 hours | TCA intermediates via PC (minutes-hours) | -- |

Detailed Protocol: Tracer Pulse Experiment Setup

Protocol 5.1: Seeding and Treatment for Adherent Cells Objective: To establish cells in a metabolic steady-state prior to tracer introduction. Materials: Cell line of choice, appropriate growth medium, tracer compound, PBS, trypsin/EDTA, cell culture plates. Procedure:

- Seed cells at a density that will reach 70-80% confluency at the time of the experiment. Use standard growth medium.

- Incubate for the appropriate period (typically 24-48h).

- Pre-incubation (Critical Step): 2 hours before tracer addition, aspirate growth medium and wash cells twice with warm PBS. Add pre-warmed, tracer-free, serum-free "starvation" medium (e.g., DMEM base without glucose/glutamine, supplemented with dialyzed serum). This depletes intracellular pools of unlabeled nutrients.

- Tracer Pulse: At time zero, quickly aspirate the starvation medium and add pre-warmed tracer-containing medium (e.g., DMEM base with 11 mM [U-13C]Glucose and 4 mM [U-12C]Glutamine, with dialyzed serum).

- Time-Course Quenching: At each predetermined time point, rapidly aspirate the tracer medium and immediately add 1 mL of cold (-20°C) 80% methanol to the well. Place the plate on a pre-chilled metal block on dry ice. Scrape cells and transfer the extract to a microcentrifuge tube stored at -80°C.

The Scientist's Toolkit: Essential Research Reagents

Table 4: Key Reagent Solutions for 13C-KFP Experiments

| Reagent/Material | Function/Benefit | Example Product/Catalog # |

|---|---|---|

| [U-13C]Glucose (99%) | Primary tracer for glycolysis, PPP, and TCA cycle. | CLM-1396 (Cambridge Isotope Laboratories) |

| [U-13C]Glutamine (99%) | Primary tracer for glutaminolysis and TCA anaplerosis. | CLM-1822 (Cambridge Isotope Laboratories) |

| Dialyzed Fetal Bovine Serum (FBS) | Removes low-MW nutrients (e.g., glucose, amino acids) to prevent tracer dilution. | 26400044 (Thermo Fisher Gibco) |

| Glucose/Glutamine-Free DMEM | Customizable base medium for precise tracer control. | A1443001 (Thermo Fisher Gibco) |

| Cold 80% Methanol (aq.) | Standard quenching agent; rapidly halts metabolism. | Prepare in-lab with LC-MS grade MeOH and H2O. |

| Cell Culture Plates (6-well) | Standard format for metabolite extraction from adherent cells. | Multiple vendors (e.g., Falcon, Corning) |

| PBS, without Ca2+/Mg2+ | For washing cells without triggering signaling events. | 10010023 (Thermo Fisher Gibco) |

Visualizations

Title: 13C-KFP Phase 1 Experimental Design Workflow

Title: Tracer Entry Points into Core Metabolic Pathways

Within the broader thesis on advancing ¹³C Kinetic Flux Profiling (KFP) protocols for systems metabolism, this phase represents the critical transition from computational modeling to practical bench execution. It focuses on the standardized cultivation of relevant cell models and the precise delivery of isotopic tracers (e.g., [U-¹³C]glucose) to initiate kinetic flux analysis. The reproducibility of this phase directly determines the quality of the time-resolved metabolomic data required for estimating in vivo metabolic flux rates in drug-treated versus control states.

Key Research Reagent Solutions & Materials

Table 1: Essential Materials for Cell Culture & Tracer Pulse-Chase

| Item/Category | Function & Rationale |

|---|---|

| Cell Line (e.g., HEK293, HepG2, primary hepatocytes) | Biologically relevant model for the metabolic pathway under investigation (e.g., glycolysis, TCA cycle). |

| Glucose- and Glutamine-Free DMEM Base Medium | Allows precise formulation of media with defined concentrations of unlabeled or ¹³C-labeled nutrients. |

| [U-¹³C]Glucose (99% atom purity) | The isotopic tracer; uniformly labeled carbon backbone enables tracking of carbon fate through metabolic networks. |

| Dialyzed Fetal Bovine Serum (dFBS) | Essential growth factors without interfering unlabeled carbon sources that would dilute the tracer. |

| Seahorse XF Calibrant Solution | For pre-experiment calibration of Seahorse XF analyzers when coupling KFP with real-time metabolic phenotyping. |

| PBS (Phosphate Buffered Saline), warm | For gentle washing of cell monolayers to remove residual unlabeled media prior to tracer pulse. |

| Quenching Solution: 60% Methanol (aq.) at -40°C | Rapidly halts metabolism at the designated time point for intracellular metabolome extraction. |

| Liquid Nitrogen | For instantaneous freezing of quenched samples to preserve metabolic state until LC-MS analysis. |

| Trypsin-EDTA (0.25%) | For adherent cell detachment and accurate cell counting prior to seeding for experiments. |

| Cell Counting Kit (e.g., Trypan Blue, automated counter) | Ensures uniform seeding density, a critical variable for reproducible metabolic assays. |

Detailed Experimental Protocols

Protocol A: Preparatory Cell Culture for KFP

Objective: To establish reproducible, logarithmically growing cell cultures in a defined medium baseline.

- Seed cells in appropriate culture vessels (e.g., 6-well plates for extraction, T-175 flasks for large-scale) at a density ensuring ~70% confluence at the experiment start.

- Culture cells in standard growth medium (e.g., high-glucose DMEM + 10% FBS) for 24h to ensure attachment and recovery.

- Adapt to Assay Medium: Aspirate standard medium. Rinse once with warm PBS. Replace with custom assay medium (e.g., DMEM base + 10mM unlabeled glucose + 2mM glutamine + 10% dFBS). Incubate for 18-24h. This step acclimates cells to experimental conditions and depletes residual unlabeled nutrients.

- Confirm Cell State: Visually inspect confluence and morphology. Optionally, measure extracellular acidification rate (ECAR) and oxygen consumption rate (OCR) via Seahorse XF assay to confirm metabolic baseline.

Protocol B: Tracer Pulse-Chase Execution

Objective: To rapidly introduce the ¹³C tracer and subsequently chase its incorporation into intracellular metabolites over a precise time course. Table 2: Example Time-Course Sampling Points

| Time Point (Minutes) | Metabolic Process Captured |

|---|---|

| 0 (pre-pulse) | Baseline, fully unlabeled metabolome. |

| 0.5, 2, 5 | Early glycolytic & pentose phosphate pathway intermediates. |

| 15, 30, 60 | TCA cycle intermediates, anaplerotic fluxes. |

| 120, 240 | Late-turnover metabolites (e.g., nucleotides, fatty acids). |

- Pulse Initiation: Aspirate adaptation medium. Quickly rinse cells twice with warm, tracer-free assay medium. Immediately add pre-warmed ¹³C-labeling medium (identical composition to assay medium but with [U-¹³C]glucose fully replacing unlabeled glucose). Note this as t=0.

- Incubation: Place plates in the incubator (37°C, 5% CO₂).

- Chase Initiation (Optional): For a true pulse-chase, after a short pulse (e.g., 2 min), rapidly aspirate labeling medium, wash twice, and add back excess unlabeled chase medium.

- Termination & Quenching: At each designated time point, rapidly aspirate medium. Immediately add 1 mL of -40°C 60% methanol quenching solution. Place plate on a pre-chilled metal block on dry ice.

- Metabolite Extraction: Add 500 µL of ice-cold water and 500 µL of ice-cold chloroform. Scrape cells on ice. Transfer homogenate to a pre-cooled microcentrifuge tube. Vortex vigorously for 1 min.

- Phase Separation: Centrifuge at 14,000 x g for 15 min at 4°C. The upper aqueous phase (containing polar metabolites for central carbon metabolism) is collected for LC-MS analysis.

- Sample Storage: Dry aqueous extracts under a gentle nitrogen stream or via vacuum concentrator. Store dried extracts at -80°C until reconstitution for LC-MS.

Data Presentation

Table 3: Typical ¹³C Labeling Data from a [U-¹³C]Glucose Pulse (M+3 Fraction of Lactate at 15 min)

| Condition (n=4) | Mean M+3 Fraction (%) | Std. Dev. (±%) | p-value vs. Control |

|---|---|---|---|

| Control (Vehicle) | 85.2 | 2.1 | -- |

| Drug A (10 µM) | 62.7 | 3.5 | 0.003 |

| Drug B (10 µM) | 88.5 | 1.8 | 0.12 |

| Glucose-Free Control | 1.2 | 0.4 | <0.001 |

Visualization Diagrams

Diagram 1: Tracer Pulse-Chase Workflow for KFP

Diagram 2: 13C-Glucose Entry into Core Metabolism

Within a 13C kinetic flux profiling (KFP) thesis, Phase 3 is the critical bridge between the biological experiment and mass spectrometry (MS) analysis. This phase must instantaneously halt metabolic activity (quenching) to preserve the in vivo isotopic labeling distribution, efficiently extract intracellular metabolites, and prepare a sample compatible with high-resolution MS. Any bias or loss introduced here directly compromises flux calculation accuracy.

Application Notes: Core Principles and Strategies

The Quenching Imperative

Metabolite turnover can occur in seconds. Quenching must be faster than the fastest metabolic conversion in the system. For microbial systems, rapid cooling with cold organic solvents (e.g., 60% aqueous methanol at -40°C to -50°C) is standard. For mammalian cells, alternative methods like rapid washing with cold saline may be preferred to minimize cell membrane disruption and metabolite leakage.

Key Consideration: The quenching agent must be compatible with the downstream extraction solvent and must not cause enzymatic degradation or isotopic scrambling.

Extraction Efficiency and Comprehensiveness

No single extraction method recovers all metabolite classes with equal efficiency. The choice is a compromise based on the target metabolome for flux analysis.

Table 1: Comparison of Common Metabolite Extraction Methods

| Method | Solvent System | Typical Temp | Key Advantages | Key Disadvantages | Best For |

|---|---|---|---|---|---|

| Cold Methanol | 40-100% MeOH in H₂O | -40°C to -20°C | Fast quenching, good for labile metabolites, simple. | Can incomplete lyse some cell types, may precipitate proteins poorly. | Polar metabolites (glycolysis, TCA intermediates). |

| Bligh & Dyer | CHCl₃:MeOH:H₂O (1:2:0.8) | 4°C | Simultaneous extraction of polar & lipids, efficient protein removal. | Chlorophyll interference, emulsion risk, chlorinated waste. | Broad profiling including lipids. |

| Hot Ethanol | 75-80% EtOH in H₂O | 80-95°C | Denatures enzymes rapidly, good for ATP-related metabolites. | May degrade heat-labile metabolites, not for volatile compounds. | Energy charge metabolites, phosphorylated sugars. |

| Acetonitrile/Methanol/Water | ACN:MeOH:H₂O (2:2:1) | -20°C | Broad metabolite coverage, good MS compatibility, minimizes degradation. | Requires very low temperature, solvent volatility. | Untargeted and targeted LC-MS. |

Sample Preparation for MS

Extracts contain compounds that can suppress ionization or contaminate the MS instrument.

- Drying & Reconstitution: Extracts are dried under vacuum or nitrogen and reconstituted in MS-compatible solvent (often phase-specific: reverse-phase = ACN/H₂O; HILIC = ACN/H₂O with buffer). Reconstitution volume impacts concentration and detection limits.

- Clean-up: Solid-phase extraction (SPE) may be used for specific classes. Filtration (0.2 µm) is mandatory to remove particulates.

- Derivatization: For GC-MS analysis (common for central carbon metabolites), derivatization (e.g., methoximation and silylation) is required to increase volatility and stability.

Detailed Protocols

Protocol A: Rapid Quenching and Cold Methanol Extraction for Yeast/Bacterial Cells

Objective: Instantaneous metabolic arrest and extraction of polar metabolites for 13C-KFP analysis via LC-MS.

Materials:

- Culture from 13C-labeling experiment (e.g., 5-10 OD-mL)

- 60% (v/v) Methanol in H₂O, pre-chilled to -50°C (in dry ice/ethanol bath)

- Pure methanol, -20°C

- Centrifuge and rotor precooled to -20°C

- Vacuum concentrator (e.g., SpeedVac)

- MS-grade water

Procedure:

- Quenching: Rapidly syringe 1 mL of culture into a 15 mL tube containing 4 mL of -50°C 60% methanol. Vortex immediately for 5-10 seconds. Hold on dry ice/ethanol bath.

- Pellet: Centrifuge at 5,000 x g, -20°C for 5 min. Decant supernatant.

- Extraction: Resuspend cell pellet in 1 mL of -20°C pure methanol. Vortex vigorously for 30 sec.

- Incubation: Place tube at -20°C for 1 hour, vortexing briefly every 15 min.

- Clarification: Centrifuge at 14,000 x g, 4°C for 10 min.

- Collection: Transfer supernatant (metabolite extract) to a new, pre-chilled tube.

- Drying: Dry the extract completely in a vacuum concentrator (~2 hours).

- Reconstitution: Reconstitute dried metabolites in 100 µL of MS-grade water or appropriate LC-MS starting solvent. Vortex thoroughly.

- Filtration: Transfer to a microcentrifuge filter (0.2 µm) and centrifuge at 14,000 x g, 4°C for 5 min. Transfer filtrate to an MS vial. Store at -80°C until analysis.

Protocol B: Dual-Phase Extraction (Modified Bligh & Dyer) for Comprehensive Profiling

Objective: Extract both polar and lipid metabolites from adherent mammalian cells for broad-coverage 13C-KFP.

Materials:

- Washed cell monolayer (on 6-well plate) from 13C experiment

- Pre-chilled Methanol

- Pre-chilled Chloroform

- Pre-chilled Water (LC-MS grade)

- Cryogenic cell scraper

- Phase-lock gel tubes (optional)

Procedure:

- Quenching/Extraction I: Aspirate medium. Immediately add 600 µL of -20°C methanol to each well. Place plate on dry ice.

- Scraping: Use a pre-cooled scraper to dislodge cells. Transfer methanol/cell suspension to a tube on dry ice.

- Extraction II: Add 400 µL of -20°C chloroform to the tube. Vortex 30 sec.

- Phase Induction: Add 200 µL of ice-cold water. Vortex vigorously for 1 min.

- Incubation: Incubate on ice for 10 min. Centrifuge at 14,000 x g, 4°C for 15 min for phase separation.

- Phase Separation: Two clear phases will form (lower organic, upper aqueous). Carefully collect both phases into separate tubes without disturbing the interphase (protein pellet).

- Drying: Dry each phase separately under vacuum or nitrogen stream.

- Reconstitution: Reconstitute polar phase in MS-grade water for LC-MS. Reconstitute lipid phase in chloroform:methanol (1:1) or isopropanol for MS.

- Storage: Store at -80°C.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for Phase 3

| Item | Function | Critical Notes for 13C-KFP |

|---|---|---|

| Quenching Solution (e.g., 60% MeOH, -50°C) | Instantaneously halts enzymatic activity to "freeze" isotopic labeling state. | Temperature is critical. Must be pre-chilled in a dry ice/ethanol slurry, not a -80°C freezer. |

| Extraction Solvents (MeOH, ACN, CHCl₃) | Disrupts cells, solubilizes metabolites, and precipitates macromolecules. | Use highest purity (MS-grade) to avoid background ions. Keep anhydrous and cold to prevent degradation. |

| Isotopically Labeled Internal Standards | Added immediately upon extraction to correct for losses during preparation and matrix effects in MS. | Crucial for quantitative KFP. Use 13C or 15N-labeled versions of target analytes if possible, or stable isotope-labeled analogs. |

| Derivatization Reagents (for GC-MS) | Modify metabolite functional groups to be volatile and thermally stable (e.g., MSTFA for silylation). | Must be anhydrous. Reaction conditions can affect some labile metabolites; optimization is required. |

| SPE Cartridges (e.g., C18, HILIC, Ion-Exchange) | Clean up specific metabolite classes, remove salts, concentrate samples. | Select phase complementary to analytical column. Can introduce selectivity bias; test recovery for key metabolites. |

| MS-Compatible Buffers (Ammonium acetate/formate) | Provide pH control and ion-pairing for chromatographic separation in LC-MS. | Use volatile buffers (e.g., ammonium acetate) at low concentration (<20 mM) to prevent source contamination. |

Visualizations

Title: Workflow for Metabolite Quenching and Extraction

Title: Phase 3 Role in the 13C-KFP Thesis

Mass spectrometry (MS) data acquisition is the critical analytical phase in 13C-Kinetic Flux Profiling (KFP) research. Following the design of tracer experiments (Phase 1), cultivation and quenching (Phase 2), and metabolite extraction (Phase 3), this phase focuses on the precise measurement of isotopomer distributions. The accuracy of this step directly determines the reliability of subsequent computational flux estimation. Within the broader KFP thesis, this phase translates a prepared biological sample into a quantitative digital dataset representing the dynamics of central carbon metabolism.

Core Principles of MS for 13C-Isotopomer Analysis

The objective is to detect and quantify the mass isotopomer distributions (MIDs) of intracellular metabolites. A mass isotopomer is a variant of a metabolite that differs only in the number of heavy isotopes (e.g., 13C) incorporated. Key MS considerations include:

- Mass Resolution: High-resolution accurate mass (HRAM) instruments (e.g., Q-Exactive Orbitrap) are preferred to resolve isobaric interferences.

- Ionization Mode: Electrospray Ionization (ESI), typically in negative mode for phosphorylated glycolytic and TCA cycle intermediates, and positive mode for amino acids and cofactors.

- Scanning Mode: Depending on the instrument, either Full Scan (FS) for high-resolution analyzers or Selected Reaction Monitoring (SRM) on triple quadrupole instruments for maximum sensitivity.

- Chromatography: Essential for separating isomers (e.g., glucose-6-phosphate vs. fructose-6-phosphate). Hydrophilic Interaction Liquid Chromatography (HILIC) is the standard.

Detailed Experimental Protocol

Instrument Calibration and Tuning

- Calibrate the mass spectrometer using the manufacturer's recommended calibration solution for the intended mass range (typically m/z 70-1000).

- Tune source parameters (spray voltage, sheath gas, auxiliary gas, capillary temperature) by infusing a standard mix of target metabolites in solvent matching the starting mobile phase composition.

- Optimize collision energies (for MS/MS or SRM methods) for each target metabolite using authentic standards.

Liquid Chromatography (HILIC) Method

- Column: SeQuant ZIC-pHILIC (150 x 4.6 mm, 5 µm) or equivalent.

- Mobile Phase A: 20 mM ammonium carbonate in water, pH 9.2 with ammonium hydroxide.

- Mobile Phase B: Acetonitrile.

- Gradient:

Time (min) % B Flow Rate (µL/min) 0 80 300 15 50 300 18 50 300 18.1 80 300 25 80 300 - Column Temperature: 40 °C.

- Injection Volume: 10-20 µL (depends on sample concentration).

Mass Spectrometry Method (Orbitrap Example)

- Ionization: ESI Negative.

- Scan Type: Full MS with polarity switching.

- Resolution: 70,000 (at m/z 200).

- Scan Range: m/z 70-1000.

- AGC Target: 1e6.

- Maximum Inject Time: 100 ms.

- Sheath Gas: 40 (arbitrary units).

- Aux Gas: 10 (arbitrary units).

- Spray Voltage: -3.0 kV.

- Capillary Temp: 320 °C.

Sample Queue and Quality Control

- Run a solvent blank at the beginning of the queue to assess carryover.

- Create a pooled QC sample by combining equal volumes of all experimental extracts. Run this QC sample every 4-6 injections to monitor instrument stability.

- Inject samples in randomized order to avoid batch effects.

- Include authentic standard mixtures at known concentrations for MID validation and potential absolute quantification.

Data Acquisition and File Management

- Acquire data in profile mode to accurately define peak shapes for integration.

- Save raw files in the instrument's native format and immediately back up to a secure server.

- Log all metadata (sample ID, injection number, file name, QC flags) in a laboratory information management system (LIMS).

Key Data Outputs and Representation

Table 1: Example Mass Isotopomer Distribution (MID) Data for Alanine

| m/z (M-H)- | Isotopomer Label (M+X) | Measured Intensity (Counts) | Corrected Fraction (M+X) | Natural Abundance Corrected Fraction |

|---|---|---|---|---|

| 88.0404 | M+0 | 1,250,000 | 0.625 | 0.580 |

| 89.0438 | M+1 | 600,000 | 0.300 | 0.285 |

| 90.0472 | M+2 | 140,000 | 0.070 | 0.125 |

| 91.0506 | M+3 | 10,000 | 0.005 | 0.010 |

Note: M+X denotes the number of 13C atoms above the monoisotopic mass. Correction algorithms (e.g., IsoCor) are applied to remove the contribution of naturally occurring 13C and other isotopes.

Table 2: Typical MS Instrument Performance Metrics for KFP

| Metric | Target Specification | Purpose in KFP |

|---|---|---|

| Mass Accuracy | < 3 ppm | Correct metabolite identification. |

| Chromatographic Peak Width (FWHM) | 5-15 seconds | Sufficient points across peak for accurate integration. |

| Signal Intensity RSD (in QC) | < 15% | Indicates acquisition stability. |

| Limit of Detection (for MID) | Signal-to-Noise > 10 for M+0 peak | Ensures detection of low-abundance isotopologues. |

| Dynamic Range | > 10^4 | Allows quantification of metabolites at varying levels. |

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item/Category | Specific Example(s) | Function in MS Acquisition |

|---|---|---|

| Chromatography Column | SeQuant ZIC-pHILIC, 150 x 4.6 mm, 5µm | Separates polar metabolites by hydrophilic interaction. |

| Mobile Phase Modifiers | Ammonium carbonate, Ammonium acetate, Ammonium hydroxide | Provides volatile buffers for LC-MS compatibility and pH control. |

| MS Calibration Solution | Pierce LTQ Velos ESI Positive/Negative Ion Cal Solution | Calibrates mass axis to ensure accurate m/z measurements. |

| Authentic Metabolite Standards | SIGMA MIX I, custom mixes from e.g., Cambridge Isotopes | Used for retention time locking, MID validation, and generation of calibration curves. |

| Internal Standards (IS) | 13C,15N-labeled cell extract or uniformly labeled compounds | Corrects for matrix effects and ionization variability. |

| Needle Wash Solvents | Methanol/Water (80:20), Acetonitrile/Water (50:50) | Minimizes carryover between sample injections. |

| Vials & Caps | LC-MS Certified Glass Vials with Pre-slit PTFE/Silicone Septa | Ensures chemical inertness and prevents contamination. |

Title: MS Data Acquisition Workflow for 13C-KFP

Title: KFP Thesis Phase Relationships

This application note details the computational workflow for converting raw isotopic labeling data from time-series 13C tracer experiments into kinetic flux maps. Positioned within a comprehensive thesis on 13C Kinetic Flux Profiling (KFP) protocol research, this phase bridges experimental metabolomics and quantitative systems biology, enabling dynamic observation of metabolic pathway activities crucial for drug mechanism-of-action studies.

Kinetic Flux Profiling moves beyond steady-state Metabolic Flux Analysis (MFA) by quantifying flux dynamics. Computational flux analysis is the engine of KFP, transforming time-resolved mass spectrometry (MS) or nuclear magnetic resonance (NMR) data into a quantitative map of reaction rates (v(t)). This allows researchers to observe how fluxes rewire in response to perturbations, such as drug treatment.

Core Computational Workflow

Title: Computational KFP workflow from data to flux map.

Detailed Protocols

Protocol 5.1: Pre-processing of Raw LC-MS/MS Data for KFP

Objective: Convert raw chromatograms into corrected mass isotopomer distributions (MIDs) for central carbon metabolites. Materials: See Scientist's Toolkit. Procedure:

- Peak Integration & Alignment: Use vendor or open-source software (e.g., XCMS, El-MAVEN) to integrate peaks for target metabolites across all time points and replicates.

- Natural Isotope Correction: Apply an in-house or published algorithm (e.g., accuCor) to subtract the contribution of natural heavy isotopes (13C, 2H, 18O, etc.) from the measured MIDs.

- Background Subtraction: Subtract the average intensity of blank injections from sample peaks.

- Normalization: Normalize metabolite intensities to internal standard peaks and cell count/protein content.

- MID Compilation: For each metabolite at each time point, compile the corrected fractional labeling (M+0, M+1, ... M+n) into a table.

Table 1: Example Processed MID Data for Pyruvate (Time Point: 2 min)

| Metabolite | Time (min) | M+0 Fraction | M+1 Fraction | M+2 Fraction | M+3 Fraction |

|---|---|---|---|---|---|

| Pyruvate | 2 | 0.45 ± 0.02 | 0.31 ± 0.01 | 0.18 ± 0.01 | 0.06 ± 0.005 |

Protocol 5.2: Construction of a KFP-Specific Metabolic Network Model

Objective: Define a stoichiometric model encompassing reactions relevant to the tracer used (e.g., [U-13C] Glucose). Procedure:

- Reaction List: Compile reactions for glycolysis, TCA cycle, pentose phosphate pathway, and anaplerotic/cataplerotic reactions. Include atom transition mappings.

- Compartmentalization: Distinguish cytosolic and mitochondrial pools where necessary (e.g., glutamate vs. α-ketoglutarate).

- Software Implementation: Encode the model in a format compatible with flux estimation tools (e.g., .xml for COBRApy, .txt for INCA). Model Constraints: Provide net reaction bounds based on physiological limits and measured uptake/secretion rates.

Protocol 5.3: Kinetic Parameter Estimation using INST-MFA

Objective: Fit kinetic flux parameters by minimizing the difference between simulated and experimental MIDs. Software: Use dedicated platforms such as INCA (Isotopomer Network Compartmental Analysis) or Wrangler. Procedure:

- Model Import: Load the metabolic network model (Protocol 5.2) into the software.

- Data Import: Input the time-series MID table (from Protocol 5.1).

- Parameter Initialization: Provide initial guesses for free fluxes (

v) and pool sizes (S). - Optimization: Run a least-squares optimization (e.g., Levenberg-Marquardt) to fit parameters.

- Cost Function: Minimize

Σ (MID_exp - MID_sim)^2 / σ^2.

- Cost Function: Minimize

- Statistical Analysis: Perform a chi-square test for goodness-of-fit and generate confidence intervals for estimated parameters via Monte Carlo or parameter continuation methods.

Table 2: Example Fitted Flux Parameters for Key Glycolytic Reactions

| Reaction | Flux (µmol/gDW/min) | 95% Confidence Interval | CV% |

|---|---|---|---|

| HK | 2.50 | [2.35, 2.65] | 3.0 |

| PFK | 2.45 | [2.28, 2.62] | 3.5 |

| PK | 2.30 | [2.10, 2.50] | 4.3 |

| LDHA | 0.40 | [0.30, 0.50] | 12.5 |

Title: Simplified kinetic flux map with fitted reaction rates (v).

The Scientist's Toolkit: Key Reagent Solutions & Software

Table 3: Essential Resources for Computational Flux Analysis

| Item | Function & Purpose | Example Product/Software |

|---|---|---|

| LC-MS Data Processing Suite | Converts raw chromatograms into peak areas and MIDs. | El-MAVEN (open source), XCMS Online, Compound Discoverer (Thermo), MassHunter (Agilent) |

| Natural Isotope Correction Tool | Corrects for inherent heavy isotopes to obtain true 13C enrichment. | accuCor R package, IsoCorrector |

| Metabolic Modeling Software | Performs isotopomer simulation and parameter fitting for KFP/INST-MFA. | INCA (MATLAB), Wrangler (Python), 13CFLUX2, OpenFLUX |

| Stoichiometric Model Database | Provides curated, atom-mapped reaction networks for model construction. | BiGG Models, Metanetx, KEGG |

| Scientific Computing Environment | Platform for custom scripting, data analysis, and visualization. | Python (SciPy, pandas), MATLAB, R |

| High-Performance Computing (HPC) Access | Speeds up computationally intensive parameter fitting and confidence interval estimation. | Local cluster or cloud-based services (AWS, Google Cloud) |

Data Interpretation and Output

The final output is a time-resolved kinetic flux map. Visualize fluxes as bar charts over time or superimpose them on pathway diagrams (as above). Key analyses include:

- Flux Control Coefficients: Quantify the sensitivity of a pathway flux to changes in enzyme activity.

- Drug-Induced Flux Rewiring: Compare flux maps between control and treated cells to identify inhibited or activated pathways.

- Metabolite Pool Size Kinetics: Correlate dynamic changes in metabolite concentrations with flux changes.

Table 4: Comparative Flux Analysis: Control vs. Drug-Treated (Glycolytic Flux at t=60 min)

| Reaction | Flux Control (µmol/gDW/min) | Flux Treated (µmol/gDW/min) | % Change | p-value |

|---|---|---|---|---|

| HK | 2.50 ± 0.08 | 1.20 ± 0.10 | -52.0 | <0.001 |

| PFK | 2.45 ± 0.09 | 1.18 ± 0.09 | -51.8 | <0.001 |

| PK | 2.30 ± 0.10 | 2.10 ± 0.11 | -8.7 | 0.12 |

| LDHA | 0.40 ± 0.05 | 0.05 ± 0.02 | -87.5 | <0.001 |

¹³C Kinetic Flux Profiling (KFP) is a sophisticated mass spectrometry-based methodology that quantifies metabolic reaction rates (fluxes) in living systems by tracing the incorporation of ¹³C-labeled nutrients over time. Within the broader thesis of KFP protocol research, this application note details its pivotal role in oncology. KFP moves beyond static metabolite measurements (metabolomics) to deliver a dynamic, functional readout of pathway activity. This is critical in cancer biology, where metabolic reprogramming is a hallmark of disease, driving proliferation, survival, and therapy resistance. By applying KFP, researchers can precisely map how oncogenic mutations alter metabolic flux, identify tumor-specific metabolic vulnerabilities, and quantitatively assess how pharmacological interventions rewire central carbon metabolism to induce therapeutic effects or reveal mechanisms of resistance.

Key Quantitative Findings in Cancer Metabolism & Drug Response

The following tables summarize core quantitative insights gained from KFP studies in cancer research.

Table 1: KFP-Derived Flux Alterations in Common Cancer Types

| Cancer Type | Key Metabolic Pathway | Flux Change vs. Normal Tissue | Associated Oncogene/Tumor Suppressor | Experimental Model |

|---|---|---|---|---|

| Glioblastoma | Oxidative Pentose Phosphate Pathway (oxPPP) | ~5-8 fold increase | EGFRvIII, IDH1 mutant | Patient-derived xenografts (PDXs) |

| Pancreatic Ductal Adenocarcinoma (PDAC) | Glycolysis to Lactate (Warburg Effect) | ~3-4 fold increase | KRAS G12D | In vitro cell lines, GEMMs |

| Triple-Negative Breast Cancer (TNBC) | Glutaminolysis | ~2-3 fold increase | c-MYC | Cell line models |

| Acute Myeloid Leukemia (AML) | Mitochondrial Oxidative Metabolism (TCA cycle) | Sustained or increased | BCR-ABL, FLT3-ITD | Primary patient cells |

| Clear Cell Renal Cell Carcinoma (ccRCC) | Gluconeogenesis from glutamine | Anapleurotic flux induced | VHL loss/HIF activation | 2D/3D cell culture |

Table 2: Quantified Drug Effects on Metabolic Flux from KFP Studies

| Drug/Target | Cancer Model | Key Fluxmetric Change | Magnitude of Change | Implicated Resistance Mechanism |

|---|---|---|---|---|

| Metformin (Complex I inhibitor) | Colorectal Cancer | ↓ TCA cycle flux (αKG->succinate) | ~60% reduction | Increased pyruvate carboxylase flux |

| CB-839 (Glutaminase inhibitor) | NSCLC (KRAS mutant) | ↓ Glutamine-derived TCA flux | ~70% reduction | Compensatory glycolytic flux increase |

| Venetoclax (BCL-2 inhibitor) in AML | AML (primary cells) | ↓ Oxidative phosphorylation (OXPHOS) flux | ~50% reduction | Upregulated fatty acid oxidation flux |

| PI3Kα inhibitors (Alpelisib) | PIK3CA-mutant Breast Cancer | ↓ Glucose uptake & glycolytic flux | ~40-50% reduction | Increased serine biosynthesis pathway flux |

| IDH1 inhibitor (Ivosidenib) | IDH1-mutant Cholangiocarcinoma | ↓ D-2-HG production, ↑ αKG levels | D-2-HG flux reduced by >90% | Emergence of alternative TCA cycle entry points |

Detailed Experimental Protocols

Protocol 1: Core KFP Workflow for Cancer Cell Drug Response

Objective: To quantify the immediate changes in central carbon metabolism induced by a targeted therapy in adherent cancer cell lines.

Materials: See "Scientist's Toolkit" below. Procedure:

- Cell Preparation: Seed cells in appropriate growth medium in parallel T-75 flasks or 6-well plates. Culture until ~70-80% confluency.

- Pre-equilibration & Drug Treatment: Replace medium with standard growth medium containing the drug of interest or DMSO vehicle. Incubate for a predetermined time (e.g., 4-24 h).

- ¹³C Tracer Pulse: Quickly wash cells twice with warm, tracer-free, serum-free medium (e.g., DMEM base). Immediately add pre-warmed ¹³C-labeling medium (e.g., [U-¹³C]-Glucose in DMEM, no serum). Place plates/flasks in the incubator.

- Time-Course Quenching: At precisely defined time points (e.g., 0, 1, 5, 15, 30, 60, 120 min), rapidly aspirate the labeling medium and quench metabolism by adding -20°C methanol (40% v/v final). Immediately place culture vessel on a dry ice/ethanol bath.

- Metabolite Extraction: Scrape cells in the cold methanol. Transfer suspension to a pre-chilled microcentrifuge tube. Add cold water and chloroform (40:20:40 MeOH:H₂O:CHCl₃). Vortex vigorously for 10 min at 4°C.

- Phase Separation: Centrifuge at 14,000 x g for 15 min at 4°C. Collect the upper aqueous phase (containing polar metabolites) into a new tube.

- Sample Analysis: Dry aqueous extracts in a vacuum concentrator. Reconstitute in LC-MS suitable solvent. Analyze via Liquid Chromatography-High Resolution Mass Spectrometry (LC-HRMS) using hydrophilic interaction chromatography (HILIC) for polar metabolites.

- Data Processing & Flux Fitting: Use specialized software (e.g., INCA, isotopomer network compartmental analysis) to correct raw MS data for natural isotope abundance, calculate ¹³C isotopologue distributions (MIDs), and fit the data to a kinetic metabolic network model to estimate metabolic fluxes.

Protocol 2:In VivoKFP in Patient-Derived Xenograft (PDX) Tumors

Objective: To measure tumor metabolic fluxes in a physiological, in vivo context following drug treatment. Procedure:

- PDX Model & Treatment: Establish PDX tumors in immunodeficient mice. Randomize mice into treatment and control groups upon tumors reaching ~200-300 mm³. Administer drug or vehicle.

- In Vivo ¹³C Infusion: At the desired time post-treatment, anesthetize the mouse. Cannulate the tail vein. Initiate a constant infusion of a ¹³C tracer (e.g., [U-¹³C]-Glucose in saline) using a precision pump for a defined period (typically 30-120 min).

- Tumor Harvest & Snap-Freezing: At the end of the infusion period, quickly excise the tumor. Using a precooled bioposy punch or scalpel, rapidly dissect a portion of the tumor (avoiding necrotic areas) and immediately freeze it in liquid nitrogen-clamped aluminum tongs (Wollenberger clamp). Store at -80°C.

- Tissue Metabolite Extraction: Pulverize the frozen tissue under liquid nitrogen using a cryomill. Weigh the powder and extract metabolites using a cold methanol/water/chloroform method (as in Protocol 1, step 5-6), scaling volumes by tissue weight.

- Blood Plasma Collection: During tumor harvest, collect blood via cardiac puncture into a heparinized tube. Centrifuge immediately to separate plasma. Extract metabolites from plasma with cold methanol.

- LC-MS & Modeling: Analyze tissue and plasma extracts via LC-HRMS. Use the plasma ¹³C enrichment time-course as the input function for the computational model to estimate in vivo tumor metabolic fluxes.

Visualization of Pathways and Workflows

Diagram 1: KFP workflow and core cancer metabolism.

Diagram 2: Oncogene-driven flux and drug mechanism.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in KFP Cancer Research | Example/Notes |

|---|---|---|

| ¹³C Tracer Substrates | Provide the isotopic label to trace metabolic fate. | [U-¹³C]-Glucose (glycolysis, PPP, TCA); [U-¹³C]-Glutamine (glutaminolysis, TCA); [1,2-¹³C]-Glucose (for pathway branching). |

| Stable Isotope-Labeled Internal Standards | Enable absolute quantification and correct for MS ionization variability. | ¹³C/¹⁵N-labeled amino acid mixes, uniformly labeled cell extracts (SILEC). |

| Polar Metabolite Extraction Kits | Standardize and optimize recovery of central carbon metabolites. | Methanol/water/chloroform-based kits from vendors like Biotage or Thermo Fisher. |

| HILIC LC Columns | Separate polar, hydrophilic metabolites for optimal MS analysis. | Waters ACQUITY UPLC BEH Amide, Millipore SeQuant ZIC-pHILIC. |

| High-Resolution Mass Spectrometer | Resolve and detect ¹³C isotopologues with high mass accuracy. | Orbitrap (Thermo) or Q-TOF (Agilent, Waters) systems coupled to UHPLC. |

| Flux Analysis Software | Model kinetic ¹³C labeling data to calculate metabolic fluxes. | INCA (isotopomer network compartmental analysis), Escher-FBA, PySCeS. |

| Specialized Cell Culture Media | Defined, serum-free media for precise tracer delivery. | Glucose- and glutamine-free DMEM base, for custom ¹³C tracer formulation. |

| In Vivo Infusion Pumps | Enable precise, constant delivery of ¹³C tracers in animal models. | Syringe pumps (e.g., from Harvard Apparatus) for tail-vein cannulation. |

Overcoming Challenges: Troubleshooting and Optimizing Your KFP Experiments

Common Pitfalls in Tracer Experiment Design and How to Avoid Them

Within the framework of advancing 13C Kinetic Flux Profiling (KFP) protocols for metabolic network analysis in drug discovery, meticulous experimental design is paramount. This document outlines common pitfalls and provides application notes for robust tracer experiments.

Table 1: Common Pitfalls, Consequences, and Mitigation Strategies

| Pitfall Category | Specific Example | Consequence | Recommended Mitigation |

|---|---|---|---|

| Tracer Selection & Purity | Using [1,2-13C]glucose instead of [U-13C]glucose for pentose phosphate pathway (PPP) flux quantitation. | Inability to resolve PPP flux from glycolysis due to insufficient labeling patterns. | Precisely define metabolic question; select tracer that yields unique, quantifiable fragments for target pathways. |

| Labeling Steady-State Assumption | Sampling before isotopic steady state in intracellular metabolites during 13C-glutamine infusion. | Incorrect flux estimates due to time-variant labeling, violating modeling assumptions. | Perform time-course pilot studies to determine steady-state time for each metabolite pool. |

| Quenching & Extraction | Slow quenching in adherent cancer cell cultures, allowing metabolic activity to continue. | Artifactual labeling patterns and concentrations not reflective of in vivo state. | Use rapid, cold (< -40°C) methanol-buffered saline quenching solution optimized for cell type. |

| Mass Spectrometry Analysis | In-source fragmentation of labile metabolites (e.g., ATP, acetyl-CoA) confounding isotopologue distributions. | Overestimation of M+1 or M+2 peaks, skewing flux calculation. | Optimize MS source conditions (low fragmentation energy, desolvation temp); use LC methods that separate isomers. |

| Tracer Dilution | Unaccounted for endogenous nutrient sources (e.g., serum glutamine in media). | Dilution of tracer label, leading to underestimated enrichment and flux rates. | Quantify and match natural isotope abundance background; use tracer mixtures (e.g., [U-13C] + [12C]) to calculate dilution. |

Detailed Protocol: Standardized 13C-Glucose Kinetic Flux Profiling in Cultured Cells

Objective: To achieve a time-resolved, high-quality dataset for central carbon metabolism flux analysis.

Materials & Reagents:

- Cells of interest (e.g., HepG2, primary hepatocytes).

- Custom, serum-free, glucose-free culture medium.

- [U-13C6] Glucose (99% atom purity).

- Quenching Solution: 60% aqueous methanol, 0.9 mM ammonium bicarbonate, pH 7.4, held at -80°C.

- Extraction Solution: 40% methanol, 40% acetonitrile, 20% water, with 0.1% formic acid, at -20°C.

- LC-MS/MS system with hydrophilic interaction chromatography (HILIC) capability.

Procedure:

Preparation & Equilibration:

- Culture cells to 70-80% confluency in standard medium.

- 24 hours pre-experiment, switch to custom, serum-free, glucose-free medium supplemented with 5 mM unlabeled glucose to standardize metabolic baseline.

- 2 hours pre-experiment, replace medium with fresh identical medium.

Tracer Pulse:

- At T=0, rapidly aspirate medium and replace with pre-warmed tracer medium (identical composition, but with 5 mM [U-13C6] glucose as sole glucose source). Record exact time.

- Place plates back into incubator (37°C, 5% CO2).

Time-Course Sampling & Quenching:

- For each biological replicate and time point (e.g., 0, 15s, 30s, 1m, 5m, 15m, 60m): a. Rapidly aspirate medium. b. Immediately add 1 mL of cold Quenching Solution (-80°C). c. Swiftly scrape cells and transfer suspension to a pre-chilled (-80°C) microcentrifuge tube. d. Store samples at -80°C for ≥30 min.

Metabolite Extraction:

- Thaw samples on ice.

- Add 0.5 mL of cold Extraction Solution.

- Vortex vigorously for 30 seconds.

- Centrifuge at 21,000 x g for 15 minutes at 4°C.

- Transfer 900 µL of supernatant to a fresh LC-MS vial.

- Dry under a gentle stream of nitrogen or vacuum concentrator.

- Reconstitute in 100 µL of LC-MS compatible solvent (e.g., 95:5 water:acetonitrile) for analysis.

LC-MS/MS Analysis:

- Inject sample onto a HILIC column (e.g., BEH Amide) maintained at 40°C.

- Use mobile phase A: 95:5 Water:Acetonitrile with 20 mM ammonium acetate, pH 9.4; B: Acetonitrile.

- Elute with a gradient from 85% B to 40% B over 10-15 minutes.

- Operate mass spectrometer in negative/positive switching electrospray ionization mode.

- Acquire data in full-scan, high-resolution mode (resolution > 60,000) to resolve isotopologues.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in 13C KFP |

|---|---|

| Stable Isotope Tracers (e.g., [U-13C6]-Glucose, [U-13C5]-Glutamine) | The core reagent. Introduces non-radioactive, detectable mass labels into metabolism to track atom fate. |

| Mass Spectrometry-Grade Solvents (Methanol, Acetonitrile, Water) | Essential for reproducible metabolite extraction and LC-MS analysis with minimal background interference. |