The FBA Protocol for Strain Design: A Comprehensive Guide for Researchers in Drug Development

This article provides a detailed guide to Flux Balance Analysis (FBA) for microbial strain design, tailored for researchers, scientists, and drug development professionals.

The FBA Protocol for Strain Design: A Comprehensive Guide for Researchers in Drug Development

Abstract

This article provides a detailed guide to Flux Balance Analysis (FBA) for microbial strain design, tailored for researchers, scientists, and drug development professionals. It covers foundational concepts of constraint-based modeling, step-by-step methodological protocols for metabolic engineering, advanced troubleshooting and optimization strategies, and critical validation and comparative analyses. By addressing key intents from exploration to validation, this guide serves as a practical resource for optimizing strains to produce novel therapeutics and biomolecules efficiently.

What is FBA? Building a Foundational Understanding for Effective Strain Design

Core Principles and Current Context

Constraint-Based Reconstruction and Analysis (COBRA) provides a mathematical framework to analyze metabolic networks at the genome scale. Within a thesis on Flux Balance Analysis (FBA) protocols for microbial strain design, this approach is foundational for predicting optimal genetic modifications to enhance production of biofuels, pharmaceuticals, or biochemicals. The methodology relies on physicochemical constraints (mass balance, reaction directionality, enzyme capacity) to define the space of possible metabolic fluxes.

Table 1: Comparison of Key Constraint-Based Modeling Techniques

| Method | Primary Constraint(s) | Typical Application in Strain Design | Mathematical Formulation |

|---|---|---|---|

| Flux Balance Analysis (FBA) | Steady-state mass balance, reaction bounds. | Predict optimal growth or target metabolite yield. | Max/Min cᵀ v, s.t. S·v = 0, lb ≤ v ≤ ub. |

| Parsimonious FBA (pFBA) | FBA constraints + minimization of total flux. | Identify energetically efficient flux distributions. | Min Σ|vᵢ|, s.t. optimal objective from FBA. |

| Flux Variability Analysis (FVA) | FBA constraints + optimal objective value range. | Determine robustness and flexibility of reaction fluxes. | Max/Min vᵢ, s.t. S·v = 0, lb ≤ v ≤ ub, cᵀ v ≥ Zₒₚₜ·α. |

| OptKnock / OptStrain | FBA constraints + binary variables for gene knockouts. | Design gene deletion strategies for overproduction. | Bi-level optimization: Max product, s.t. Max growth. |

| Minimal Cut Sets (MCS) | Network connectivity and functionality. | Find minimal reaction/ gene sets to delete to force flux. | Computed via duality of elementary modes. |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions and Materials for FBA-Driven Strain Design

| Item | Function in Protocol |

|---|---|

| Genome-Scale Metabolic Model (GSMM) | Structured knowledgebase (SBML format) containing stoichiometric matrix S, gene-protein-reaction rules, and exchange reaction definitions. |

| COBRA Toolbox (MATLAB) or cobrapy (Python) | Software suites for loading models, applying constraints, performing FBA/pFBA/FVA, and simulating knockouts. |

| Defined Growth Media Formulation | List of exchange reaction bounds (lb) specifying available carbon, nitrogen, phosphate, sulfur, and oxygen sources for in silico simulation. |

| Biolog Phenotype MicroArray Data | Experimental data on substrate utilization and chemical sensitivity used to validate and refine model constraints. |

| 13C-Metabolic Flux Analysis (13C-MFA) Data | Quantitative intracellular flux measurements used as an additional constraint set or for model validation. |

| CRISPR/Cas9 Genome Editing System | Experimental toolkit for implementing in silico-predicted gene knockouts, knockdowns, or integrations in the target microbial strain. |

| LC-MS / GC-MS Platform | For quantifying extracellular metabolite exchange rates (uptake/secretion) and intracellular metabolite levels to constrain models and validate predictions. |

Application Notes & Detailed Protocols

Protocol: Performing FBA for Target Metabolite Overproduction

Objective: Use FBA to predict the maximum theoretical yield of a target biochemical (e.g., succinate) in E. coli and identify potential genetic intervention strategies.

Materials:

- A curated E. coli GSMM (e.g., iML1515).

- Cobrapy installed in a Python environment.

- Jupyter Notebook for documentation.

Procedure:

- Model Acquisition and Loading: Download the model in SBML format. Load it using cobrapy:

model = cobra.io.read_sbml_model('iML1515.xml'). - Define Physiological Constraints: Set the glucose uptake rate (e.g.,

EX_glc__D_e: lower_bound = -10 mmol/gDW/hr). Set oxygen uptake for aerobic (EX_o2_e: lower_bound = -20) or anaerobic conditions. Define other nutrient availabilities based on your defined minimal medium. - Set the Objective Function: For wild-type growth simulation, the objective is typically biomass:

model.objective = 'BIOMASS_Ec_iML1515_core_75p37M'. Solve usingsolution = model.optimize(). - Predict Maximum Product Yield: Change the objective to the secretion reaction of the target metabolite (e.g.,

EX_succ_e). Re-solve FBA. The flux through this exchange reaction is the maximum theoretical yield. - Identify Essential Genes for Production (OptKnock-like): Use a strain design algorithm. In cobrapy, use

cobra.flux_analysis.double_gene_deletionor employ thecameopackage for more advanced functions. The algorithm will search for gene/reaction knockouts that couple target metabolite production to growth. - Validate Prediction with FVA: Perform FVA on the wild-type and designed mutant models to assess the stability and flexibility of the predicted production flux under optimal growth conditions.

- Export Results: Document the predicted growth rate, production flux, and suggested gene knockouts. Prepare the model and constraint set for sharing.

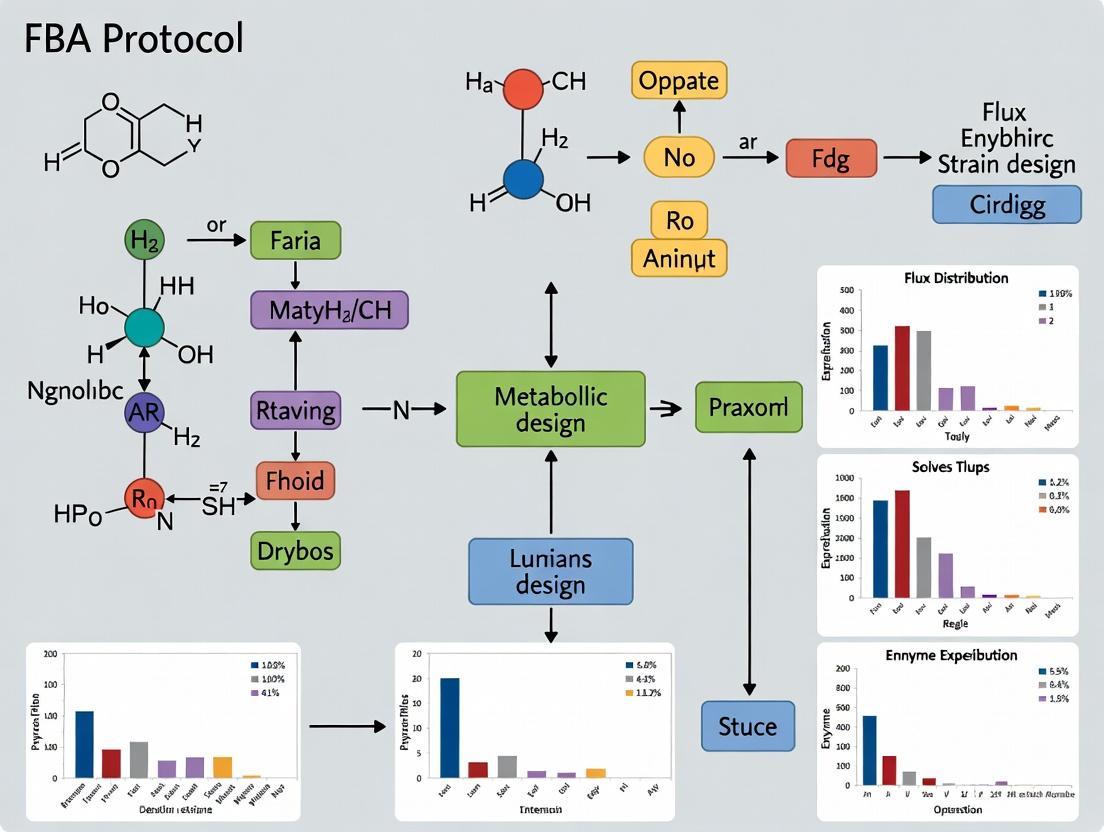

Title: FBA Protocol for Strain Design Workflow

Protocol: Integrating Omics Data to Contextualize Metabolic Models

Objective: Create a tissue- or condition-specific model by integrating transcriptomic data into a generic human metabolic model (e.g., Recon3D) using the INIT algorithm.

Materials:

- Generic human metabolic model (Recon3D).

- Transcriptomics data (RNA-Seq) for your target cell type/condition (as RPKM or TPM values).

- Software: Cobrapy and the

mopedorcameopackage for data integration in Python, or the CORDA algorithm.

Procedure:

- Data Preprocessing: Normalize transcriptomic data (e.g., TPM). Map gene identifiers in the dataset to the gene identifiers used in the metabolic model.

- Define Core and Penalized Reactions: Manually curate a small set of high-confidence metabolic functions that must be active in your cell type (CORE set). Use transcript levels to assign a confidence score (weight) to each reaction based on its associated genes (e.g., using GPR rules).

- Run the INIT Algorithm: Formulate and solve a linear programming problem that maximizes the sum of fluxes weighted by the transcript-derived confidence scores, subject to mass balance and network connectivity constraints that force inclusion of the CORE set.

- Generate the Contextualized Model: The algorithm output is a subset of the global network—a context-specific model containing only reactions deemed active.

- Validate the Functional Model: Test if the contextualized model can perform known metabolic functions (e.g., ATP production, known secretion profiles) by performing FBA. Compare predictions against known metabolic phenotypes or 13C-MFA data.

Title: Omics Data Integration to Build Context-Specific Models

Application Notes: Core Principles in Strain Design Research

Flux Balance Analysis (FBA) is a cornerstone constraint-based modeling approach for analyzing metabolic networks, enabling quantitative prediction of metabolic flux distributions essential for strain design in biotechnology and drug development. Its application is pivotal for predicting optimal genetic modifications to enhance product yield, such as biofuels, pharmaceuticals, or biochemicals.

Objectives

The primary objective in FBA is to identify a flux distribution that maximizes or minimizes a defined linear objective function, representing a cellular goal. In strain design, common objectives include:

- Biomass Maximization: Simulating optimal growth conditions.

- Product Yield Maximization: Optimizing fluxes toward a target metabolite (e.g., succinate, penicillin precursor).

- ATP Production Minimization: Studying metabolic efficiency.

- Nutrient Uptake Rate Minimization: Identifying minimal media requirements.

Key Constraints

FBA solutions are bounded by physiochemical and environmental constraints applied to the stoichiometric model (S).

Table 1: Core Constraints in FBA for Strain Design

| Constraint Type | Mathematical Representation | Biological & Experimental Basis | Typical Value Range (E. coli example) |

|---|---|---|---|

| Steady-State | S · v = 0 | Internal metabolite concentrations do not change over time. | N/A (Fundamental assumption) |

| Enzyme Capacity | vmin ≤ v ≤ vmax | Thermodynamic irreversibility and measured enzyme V_max. | vmin = 0 for irreversible rxns; vmax from 10-100 mmol/gDW/h. |

| Nutrient Uptake | vuptake ≤ Uptakemax | Measured substrate consumption rate from chemostat or batch culture. | Glucose: ~10 mmol/gDW/h. O2: ~15 mmol/gDW/h. |

| Secretion | vsecretion ≤ Secretionmax | Measured product or by-product excretion rate. | Acetate: 0-20 mmol/gDW/h. |

| Gene Deletion | v = 0 | Simulating knockout of specific gene(s) encoding enzyme(s). | Applied to specific reaction fluxes. |

Solutions and Interpretation

The solution is a flux vector (v) optimizing the objective (Z = c^T · v). The problem is solved via Linear Programming (LP). Results must be interpreted within the context of model limitations (e.g., static, no regulation).

Table 2: Common FBA Outputs and Their Significance in Strain Design

| Output | Description | Relevance to Strain Design |

|---|---|---|

| Optimal Growth Rate (μ) | Predicted maximum biomass yield. | Benchmark for strain fitness under simulated conditions. |

| Target Flux (v_product) | Predicted flux through product-forming reaction. | Primary indicator of theoretical production capacity. |

| Shadow Price | Change in objective per unit change in metabolite availability. | Identifies limiting metabolites; guides media formulation. |

| Reduced Cost | Sensitivity of optimal solution to flux through a non-active reaction. | Identifies reactions that, if altered, could improve the objective. |

Protocols for FBA in Strain Design

Protocol 2.1: Performing a Standard FBA for Product Yield Prediction

Objective: To computationally predict the maximum theoretical yield of a target metabolite (e.g., Succinate) from a defined carbon source.

Materials: See "Scientist's Toolkit" below. Procedure:

- Model Import/Curation: Load a genome-scale metabolic reconstruction (GEM) (e.g., iML1515 for E. coli) into analysis software (e.g., COBRApy, RAVEN Toolbox).

- Define Environmental Constraints:

- Set the carbon source uptake rate (e.g., glucose: -10 mmol/gDW/h).

- Set oxygen uptake for aerobic/anaerobic conditions.

- Allow typical by-product secretion (e.g., acetate, CO2).

- Define the Objective Function:

- For maximum product yield, set the objective to maximize the flux through the reaction representing succinate export (e.g.,

EX_succ_e).

- For maximum product yield, set the objective to maximize the flux through the reaction representing succinate export (e.g.,

- Apply Genetic Constraints: To simulate a knockout strain, set the flux through the reaction(s) catalyzed by the deleted gene(s) to zero (e.g., set

v_PFL= 0 to knock out pyruvate formate-lyase). - Solve the Linear Programming Problem: Execute the FBA solver.

- Extract and Validate Solution:

- Record optimal product flux and biomass flux.

- Calculate yield: (Product flux) / (Carbon source uptake flux).

- Perform flux variability analysis (FVA) to check solution uniqueness.

Protocol 2.2: Gene Knockout Prediction using OptKnock

Objective: To identify gene deletion strategies that couple growth with enhanced product formation.

Procedure:

- Setup Base Model: Complete steps 2.1.1-2.1.3.

- Formulate the OptKnock Problem: This bi-level optimization problem is framed as: Maximize (product flux) such that biomass is maximized, subject to K reaction deletions.

- Specify Deletion Number: Set the maximum number of allowed gene deletions (K), typically starting with K=1-3.

- Solve using MILP Solver: Use a mixed-integer linear programming (MILP) solver (e.g., Gurobi, CPLEX) via a framework like COBRApy to find the optimal deletion set.

- Analyze and Rank Solutions: The output is a list of suggested gene deletion sets. Rank them by predicted product yield and growth rate.

Visualizations

Title: FBA Computational Workflow

Title: FBA Constraints & Objective Applied to Network

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Computational Tools for FBA

| Item | Category | Function in FBA Protocol |

|---|---|---|

| Genome-Scale Model (GEM) (e.g., iML1515, Yeast8) | Data/Software | Community-curated metabolic network reconstruction; the foundational matrix (S) for simulations. |

| COBRApy / RAVEN Toolbox | Software | MATLAB/Python toolboxes providing functions to constrain, simulate, and analyze metabolic models. |

| LP/MILP Solver (e.g., Gurobi, CPLEX, GLPK) | Software | Computational engine that performs the optimization to find the flux solution. |

| Jupyter Notebook / MATLAB IDE | Software | Environment for scripting analysis workflows, ensuring reproducibility. |

| Phenotypic Growth Data (e.g., uptake/secretion rates) | Experimental Reagent | Quantitative data from bioreactor or microplate experiments to set realistic model constraints (v_max). |

| Knockout Strain Library (e.g., Keio collection) | Biological Material | Physical strains for in vivo validation of FBA-predicted essential genes or beneficial deletions. |

| GC-MS / HPLC System | Analytical Equipment | Measures extracellular metabolite concentrations (secretions) to validate model predictions. |

Application Note 1: Flux Balance Analysis (FBA) for Antibiotic-Producing Strain Design

Flux Balance Analysis is a cornerstone computational method in systems biology for predicting the flow of metabolites through a metabolic network. In the context of strain design for antibiotic production, FBA enables the identification of genetic modifications that maximize the yield of target secondary metabolites, such as penicillin from Penicillium chrysogenum or avermectin from Streptomyces avermitilis. The protocol integrates genomic-scale metabolic models (GEMs) with linear programming to optimize for an objective function, typically biomass or antibiotic precursor production.

Key Quantitative Data from Recent Studies:

Table 1: FBA-Predicted vs. Experimental Yield Improvements in Antibiotic Production

| Host Strain | Target Antibiotic | Key Genetic Modification (Predicted by FBA) | Predicted Yield Increase (%) | Experimental Yield Increase (%) | Reference Year |

|---|---|---|---|---|---|

| S. coelicolor | Actinorhodin | Deletion of pta-ackA pathway | 45 | 38 | 2023 |

| P. chrysogenum | Penicillin G | Overexpression of pcbAB, pcbC, penDE | 220 | 185 | 2024 |

| S. avermitilis | Avermectin B1a | Knockout of gtt2, enhancement of ave genes | 70 | 65 | 2023 |

| E. coli (Engineered) | Erythromycin Precursor (6-deoxyerythronolide B) | Optimization of methylmalonyl-CoA supply | 300 | 260 | 2024 |

Detailed Protocol: FBA-Guided Strain Design for Enhanced Antibiotic Production

Objective: To computationally design and experimentally validate a Streptomyces strain with enhanced polyketide antibiotic yield.

Materials:

- Genome-scale metabolic model (e.g., iMK1208 for S. coelicolor)

- Constraint-based modeling software (CobraPy, Matlab COBRA Toolbox)

- Wild-type Streptomyces strain

- CRISPR-Cas9 or conjugative plasmid system for genetic modification

- HPLC-MS for antibiotic quantification

Procedure:

Model Curation and Contextualization:

- Acquire a relevant GEM from a repository like BioModels.

- Constrain the model using experimental data (e.g., substrate uptake rates from growth assays, measured ATP maintenance costs).

- Set the biochemical production of the target antibiotic (or its direct precursor) as the objective function.

In Silico Intervention Analysis:

- Perform gene knockout simulations (e.g., using OptKnock or RobustKnock algorithms) to identify gene deletions that couple growth with high antibiotic flux.

- Perform gene addition/enhancement simulations (using pFBA or MOMA) to pinpoint potential overexpression targets (biosynthetic genes, precursor suppliers).

- Validate predicted essential genes to avoid lethal designs.

Genetic Implementation:

- For gene deletions: Design sgRNAs and homologous repair templates for CRISPR-Cas9 editing of the target loci in the host strain.

- For gene overexpression: Clone the target genes into a strong, constitutive expression plasmid and introduce via conjugation.

- Verify all genetic modifications via PCR and sequencing.

Experimental Validation:

- Cultivate the engineered and wild-type strains in parallel in optimized production media.

- Measure growth (OD600) and substrate consumption over time.

- Extract metabolites at stationary phase and quantify antibiotic titer using HPLC-MS with a standard curve.

- Compare experimental yield increase to FBA predictions.

FBA-Guided Strain Design Workflow

Research Reagent Solutions for FBA-Driven Antibiotic Strain Engineering:

| Reagent/Material | Function in Protocol |

|---|---|

| CobraPy Python Package | Primary software for loading GEMs, applying constraints, and running FBA simulations. |

| CRISPR-Cas9 Kit for Actinobacteria | Enables precise, marker-less gene deletions or insertions in slow-growing Streptomyces. |

| pIJ10257 Conjugative Plasmid | Shuttle vector for stable gene overexpression in Streptomyces from E. coli. |

| HPLC-MS System | Gold-standard for accurate identification and quantification of complex antibiotic molecules. |

| Defined Minimal Media (SMMS) | Provides consistent, chemically defined growth conditions for reproducible flux measurements. |

Application Note 2: FBA-Informed Antigen Selection and Vaccine Vector Design

FBA's utility extends to vaccine development by optimizing microbial chassis (e.g., E. coli, S. cerevisiae, Pichia pastoris) for high-yield recombinant antigen or virus-like particle (VLP) production. FBA models can predict metabolic bottlenecks during heterologous protein expression and guide engineering to redirect resources toward biomass and target protein synthesis, enhancing yield and process scalability for subunit vaccines.

Key Quantitative Data from Recent Studies:

Table 2: Metabolic Engineering for Vaccine Antigen/VLP Production Yield

| Host Organism | Vaccine Target | FBA-Informed Modification | Final Antigen Yield (mg/L) | Fold Increase vs. WT | Reference Year |

|---|---|---|---|---|---|

| Pichia pastoris | Hepatitis B Surface Antigen (HBsAg) | Methanol utilization pathway optimization | 520 | 3.5 | 2023 |

| E. coli BL21(DE3) | HPV L1 Protein (VLP) | Knockout of ackA-pta, T7 RNA polymerase tuning | 120 | 4.0 | 2024 |

| S. cerevisiae | SARS-CoV-2 RBD | Engineering of ER folding & secretory pathways | 85 | 5.2 | 2023 |

| Baculovirus/Insect Cell | Influenza Hemagglutinin VLP | Modulation of glycosylation & apoptosis pathways | 310 | 2.1 | 2024 |

Detailed Protocol: FBA for High-Yield Recombinant Antigen Production in Pichia pastoris

Objective: To use FBA to identify metabolic targets for improving the yield of a recombinant antigen in P. pastoris and validate the design.

Materials:

- P. pastoris GEM (e.g., iLC915)

- Fermentation bioreactor with methanol control

- Plasmid with antigen gene under AOX1 promoter

- ELISA kit for antigen quantification

- Metabolite analyzers (for extracellular flux data)

Procedure:

Dynamic Flux Balance Analysis (dFBA):

- Constrain the model with time-course data from a baseline fermentation (growth, glucose/methanol uptake, antigen production rate).

- Run dFBA simulations to identify periods of metabolic imbalance or insufficient precursor supply (e.g., amino acids, ATP, NADPH) during the methanol induction phase.

Target Identification:

- Use Minimization of Metabolic Adjustment (MOMA) to simulate the overexpression of enzymes in bottlenecked pathways (e.g., methanol oxidation, pentose phosphate pathway for NADPH).

- Use OptKnock to propose gene deletions that may reduce by-product formation (e.g., glycerol) and force flux toward antigen synthesis.

Strain Construction & Fermentation:

- Integrate overexpression cassettes for target genes (e.g., FLD1, ZWF1) into the Pichia genome.

- Perform fed-batch fermentations in a bioreactor: an initial growth phase on glycerol, followed by induction with a controlled methanol feed.

Validation and Scale-Up:

- Monitor biomass, substrate, and metabolite concentrations throughout the fermentation.

- Quantify antigen concentration in culture supernatant via ELISA at multiple time points.

- Compare the antigen yield and productivity (mg/L/h) to the baseline strain and the dFBA prediction.

FBA for Vaccine Antigen Production Optimization

Research Reagent Solutions for FBA-Driven Vaccine Development:

| Reagent/Material | Function in Protocol |

|---|---|

| iLC915 Genome-Scale Model | Comprehensive metabolic network of P. pastoris for in silico predictions. |

| pPICZα Expression Vector | Pichia integration vector with AOX1 promoter for methanol-inducible, secreted expression. |

| Methanol Control Bioreactor | Enables precise feeding of methanol, the inducer and carbon source for AOX1 promoter. |

| Antigen-Specific ELISA Kit | High-throughput, quantitative measurement of recombinant antigen concentration. |

| Extracellular Flux Analyzer | Measures real-time metabolite consumption/production rates to constrain the FBA model. |

Within a broader thesis on Flux Balance Analysis (FBA) protocols for strain design research, the foundational step is the acquisition, reconstruction, and validation of a high-quality Genome-Scale Metabolic Model (GEM). GEMs are computational representations of the metabolic network of an organism, enabling the prediction of phenotypic behaviors from genotypic data. Public databases such as BiGG and ModelSEED are indispensable resources that provide curated models, standardized metabolites, and reaction identifiers, ensuring reproducibility and interoperability in metabolic engineering and drug discovery research.

Public databases host essential data for GEM reconstruction and analysis. The following table summarizes the core features and current status of two primary resources.

Table 1: Comparative Overview of Key GEM Databases

| Feature | BiGG Models | ModelSEED |

|---|---|---|

| Primary Focus | Curated, high-quality models for specific organisms. | Automated reconstruction pipeline for genome annotation to draft models. |

| Core Resource | A knowledgebase of standardized biochemical reactions, metabolites, and genes. | A consistent biochemical database and model reconstruction platform. |

| Number of Models | >100 highly curated models (e.g., E. coli iJO1366, human RECON). | Thousands of draft and curated models across diverse taxa. |

| Key Access Method | Web interface (bigg.ucsd.edu) and API for data retrieval. | Web-based interface and API via the KBase platform. |

| Data Standardization | Strict namespace (BiGG IDs) for metabolites and reactions. | Own namespace, with mappings to BiGG and MetaCyc. |

| Recent Update | BiGG 2 (2022) includes expanded model and reaction coverage. | Integrated with KBase; continuous updates with new genomes. |

| Primary Use Case | Simulation-ready models for detailed mechanistic studies. | Rapid generation of draft models for novel or less-studied organisms. |

Protocol 1: Retrieving and Validating a GEM from a Public Database

This protocol details the steps to acquire a pre-existing GEM from the BiGG database and perform basic validation, a prerequisite for FBA-based strain design.

Materials and Reagents

Research Reagent Solutions:

- Computer with Internet Access: For accessing online databases and tools.

- Python Environment (≥3.8): With essential packages (cobra, requests, pandas).

- Cobrapy Package: A Python toolbox for constraint-based modeling.

- Jupyter Notebook: For interactive code execution and documentation.

- Spreadsheet Software (e.g., Excel, LibreOffice Calc): For manual inspection of model files.

Procedure

Database Query:

- Navigate to the BiGG Models website (

http://bigg.ucsd.edu). - Use the "Models" search function to locate your organism of interest (e.g., "Escherichia coli str. K-12 substr. MG1655").

- Identify the preferred model (e.g.,

iJO1366). Note its BiGG ID.

- Navigate to the BiGG Models website (

Data Retrieval:

- Manual Download: On the model's page, download the model in SBML (Systems Biology Markup Language) format.

- Programmatic Access (via API): Use the following Python script to retrieve the model.

Model Loading and Basic Validation:

- Load the model into cobrapy and perform essential sanity checks.

- Load the model into cobrapy and perform essential sanity checks.

Curation Check:

- Compare the model's statistics (reaction/metabolite counts) against the information listed on its database page.

- Verify the presence of known essential pathways for your research context.

Protocol 2: Drafting a GEM Using ModelSEED

For organisms not available in curated databases, this protocol outlines generating a draft model using the automated ModelSEED pipeline.

Procedure

Input Preparation:

- Obtain the genome sequence of your target organism in FASTA format (

.fnafile). - Ensure the genome is annotated, or prepare to use the RAST annotation pipeline within KBase.

- Obtain the genome sequence of your target organism in FASTA format (

Model Reconstruction via KBase:

- Create an account on the KBase platform (

https://www.kbase.us). - Create a new Narrative.

- Use the "Build Metabolic Model" app. Upload your genome FASTA file.

- Select the appropriate taxonomic classification and annotation parameters.

- Execute the app. It will run RAST for annotation and the ModelSEED pipeline to construct a draft GEM.

- Create an account on the KBase platform (

Model Retrieval and Post-Processing:

- Once the app completes, the draft model will be available as a data object in your Narrative.

- Use the "Export" function to download the model in SBML format.

- Load the draft model in cobrapy. Be aware that draft models often require significant gap-filling and curation.

Initial Gap-Filling (Conceptual):

- Use the

cobrapygap-filling functions or dedicated tools likeCarveMeormetaGEMto add missing reactions based on phenotypic data or phylogenetic similarity. - This step is iterative and organism-specific.

- Use the

Visualizations

Title: GEM Acquisition Workflow for FBA Thesis

Title: From GEM to FBA Outputs in Strain Design

Within the framework of a thesis on Flux Balance Analysis (FBA) protocols for microbial strain design, the primary and most consequential decision is the explicit definition of the biological objective function. This choice mathematically encodes the cellular "goal" and directly dictates the computational predictions and subsequent experimental strategies. This application note delineates the experimental and analytical protocols for three principal design goals: Maximizing Biomass Yield (for growth-coupled production), Maximizing Growth Rate (for host fitness and scalability), and Maximizing Synthesis Rate of a Novel Compound (for discovery and non-native pathways).

Quantitative Comparison of Design Goals

Table 1: Comparative Analysis of Primary Strain Design Objectives

| Design Goal | Primary Objective Function | Typical FBA Formulation | Key Metric | Optimal Use Case | Common Trade-offs |

|---|---|---|---|---|---|

| Maximize Biomass Yield | Maximize mmol product / mmol substrate | Max v_product / v_substrate s.t. steady-state & v_biomass ≥ min |

Yield (Yp/s) | Industrial bioprocessing; Substrate-cost sensitive processes | Often reduces absolute titer and growth rate; May require knock-outs. |

| Maximize Growth Rate | Maximize biomass reaction flux | Max v_biomass s.t. steady-state |

Specific Growth Rate (μ, hr⁻¹) | Generating robust chassis strains; High-cell-density fermentations | Native metabolism dominates; May shunt carbon away from desired products. |

| Maximize Novel Compound Synthesis | Maximize flux through target reaction | Max v_target s.t. steady-state |

Production Rate (mmol/gDCW/hr) | Discovery and prototyping of non-natural products; Pathway feasibility testing | Can lead to non-viable, growth-arrested in silico designs. |

Data synthesized from current literature on metabolic engineering objectives (2023-2024).

Experimental Protocols

Protocol 3.1: Establishing Baseline Metrics for Goal Evaluation

Purpose: To characterize the wild-type or baseline strain under standard conditions, providing data for constraint setting in FBA models. Materials: See "Research Reagent Solutions" (Section 5). Procedure:

- Inoculum Preparation: Grow strain in 5 mL seed medium overnight.

- Batch Cultivation: Dilute to OD600 0.05 in triplicate 250 mL baffled flasks with 50 mL defined medium. Incubate with shaking.

- Growth Monitoring: Measure OD600 every hour for 12 hours, then every 2-4 hours until stationary phase.

- Substrate & Product Analysis: Take 1 mL samples at mid-exponential and stationary phases. Centrifuge (13,000 x g, 5 min). Analyze supernatant via HPLC or GC-MS for substrate (e.g., glucose) consumption and any native product formation.

- Calculation: Calculate μ_max (hr⁻¹) from ln(OD) plot. Calculate biomass yield (gDCW/mmol Glc) and any native product yields.

Protocol 3.2: Strain Design & Evaluation for Yield Maximization

Purpose: To engineer and validate a strain where product formation is obligately linked to growth. Procedure:

- In Silico Design (FBA):

- Load genome-scale model (GEM).

- Set objective: Max

v_product / v_substrate. - Add constraint:

v_biomass ≥ 0.05 * μ_max_wildtype. - Perform Minimization of Metabolic Adjustment (MOMA) or OptKnock to identify gene knockout targets.

- Genetic Implementation: Execute knockout(s) using CRISPR-Cas9 or λ-Red recombinering.

- Chemostat Validation:

- Grow engineered strain in continuous culture at a fixed dilution rate (D = 0.5 * μ_max).

- After 5-10 volume changes, measure steady-state product titer, biomass, and residual substrate.

- Key Output: Plot product yield vs. biomass yield; target is a positive correlation.

Protocol 3.3: Adaptive Laboratory Evolution (ALE) for Growth Maximization

Purpose: To improve the growth rate and fitness of a chassis strain under specific industrial conditions. Procedure:

- Setup: Prepare serial transfer lines (≥ 6) in biological duplicate. Use desired production medium.

- Evolution: Daily, transfer an aliquot (typically 1-10%) to fresh medium. Monitor OD600.

- Monitoring: When accelerated growth is observed, sample populations for sequencing and phenotyping.

- Characterization: Isolate clones. Re-run Protocol 3.1. Integrate evolved mutations as constraints into the GEM (e.g., up-/down-regulation of reaction bounds).

Protocol 3.4: Screening for Novel Compound Synthesis

Purpose: To test the functionality of heterologous pathways and detect novel compounds. Procedure:

- Pathway Implementation: Assemble and transform heterologous gene expression construct(s).

- Cultivation: Grow transformants in deep-well plates with inducing conditions. Include empty-vector controls.

- Metabolite Extraction: Quench metabolism at mid-log phase. Lyse cells. Extract metabolites with solvent (e.g., 40:40:20 MeOH:ACN:H2O).

- Analysis: Perform untargeted LC-MS/MS. Use high-resolution mass spectrometry.

- Data Processing: Use bioinformatics tools (e.g., MZmine, GNPS) to align peaks, identify isotopes/adducts, and compare against controls to highlight novel features.

Visualizations

Title: Decision Workflow for Selecting FBA Design Goal

Title: Metabolic Network with Different FBA Objective Functions

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Strain Design & Evaluation Experiments

| Reagent/Material | Supplier Examples | Function in Protocols |

|---|---|---|

| Defined Minimal Medium Kit | Teknova, Sunrise Science | Provides reproducible, chemically defined growth conditions essential for accurate FBA constraint setting and yield calculations (Protocol 3.1). |

| Genome-Scale Metabolic Model (GEM) | BiGG, MetaNetX, CarveMe | In silico representation of metabolism (e.g., E. coli iML1515, S. cerevisiae Yeast8). Core tool for FBA simulations in all design goals. |

| CRISPR-Cas9 Gene Editing System | Addgene (Plasmids), NEB (Enzymes) | Enables precise gene knockouts/insertions for implementing in silico designs from Protocol 3.2. |

| Biolector or Similar Microbioreactor | Beckman Coulter, m2p-labs | Allows high-throughput, parallel monitoring of growth (OD, pH, DO) and fluorescence in microliter volumes, critical for screening (Protocol 3.4). |

| HPLC System with RI/UV Detector | Agilent, Waters, Shimadzu | Quantifies substrate consumption (e.g., glucose) and product formation for yield calculations (Protocols 3.1, 3.2). |

| High-Resolution LC-MS/MS System | Thermo Fisher (Q-Exactive), Sciex | Enables untargeted metabolomics for novel compound detection and identification (Protocol 3.4). |

| DNA Sequencing Kit (Whole Genome) | Illumina (NovaSeq), Oxford Nanopore | Identifies mutations acquired during Adaptive Laboratory Evolution (Protocol 3.3). |

| Flux Analysis Software (e.g., COBRApy) | The COBRA Project | Python toolbox for performing FBA, OptKnock, and related algorithms to define design goals. |

A Step-by-Step FBA Protocol: From Model Curation to Strain Blueprint

The construction of a high-quality Genome-Scale Metabolic Model (GEM) is the foundational step in any Flux Balance Analysis (FBA) protocol for rational strain design. GEMs are mathematically structured knowledge bases that represent the metabolic network of an organism. Within a strain design pipeline, a well-curated GEM enables the in silico simulation of metabolic fluxes, prediction of gene knockout/gene addition effects, and identification of optimal pathways for enhanced production of target biochemicals or biomolecules.

This Application Note details the systematic protocol for acquiring and curating a high-quality GEM, ensuring it is fit for purpose in downstream FBA and computational strain optimization workflows.

High-quality GEMs can be acquired from multiple repositories. The choice depends on the target organism, desired curation level, and intended application. The following table summarizes the primary sources.

Table 1: Primary Sources for Acquiring Genome-Scale Metabolic Models

| Source Name & URL | Description & Scope | Key Features for Strain Design | Typical File Formats |

|---|---|---|---|

| ModelSEED https://modelseed.org/ | Automated reconstruction platform linked to the RAST annotation server. | Rapid generation of draft models for a wide array of genomes; good starting point for non-model organisms. | SBML, JSON |

| Path2Models (BioModels) https://www.ebi.ac.uk/biomodels/ | Large collection of models generated through automated pipelines. | Broad taxonomic coverage; useful for comparative analysis. | SBML |

| BiGG Models http://bigg.ucsd.edu | A knowledge base of highly curated, standardized models. | Gold standard for model quality; rigorous namespace (BiGG IDs) facilitates integration and comparison. Essential for robust FBA. | SBML, JSON, MAT |

| AGORA & VMH https://www.vmh.life | Resource for human and gut microbiome metabolism (AGORA). | Crucial for strain design in biotherapeutics and understanding host-microbe interactions in drug development. | SBML, MAT, XLS |

| CarveMe https://carveme.readthedocs.io/ | Python-based tool for automated draft model reconstruction. | Creates compartmentalized, ready-to-use models from genome annotation; uses a curated universal model as template. | SBML |

| KBase https://www.kbase.us/ | Integrated systems biology platform. | End-to-end environment: from genome assembly to model reconstruction, simulation, and analysis. | Native to platform, exportable as SBML |

Protocol: A Step-by-Step Workflow for Model Acquisition and Curation

This protocol outlines a systematic approach to obtain and refine a GEM for strain design applications.

Phase I: Acquisition of a Draft Model

Objective: Select and download a starting model appropriate for your target organism. Procedure:

- Identify Target Organism: Determine the scientific or industrial relevance (e.g., Escherichia coli K-12 for biochemical production, Saccharomyces cerevisiae for biofuels, CHO cells for therapeutic protein synthesis).

- Search Repositories: Query the sources in Table 1 using the organism name or taxonomy ID.

- Selection Criteria: Prioritize models that are:

- Manually Curated: (e.g., from BiGG) if available for your organism.

- Recent: Check publication date to ensure genomic and biochemical knowledge is current.

- Experimentally Validated: Models with growth or phenotype predictions tested against experimental data are preferable.

- Download Model: Acquire the model file, preferring the Systems Biology Markup Language (SBML) format for maximum compatibility with analysis tools (CobraPy, RAVEN, etc.).

Phase II: Diagnostic Evaluation and Gap Analysis

Objective: Assess the quality and completeness of the draft model. Procedure:

- Load Model: Import the SBML file into a preferred software environment (e.g., Python with CobraPy, MATLAB with COBRA Toolbox).

- Perform Basic Diagnostic Checks:

- Reaction & Metabolite Count: Record statistics.

- Check for Mass/Charge Balance: Identify reactions that violate conservation laws.

- Test for Growth on Basic Media: Simulate growth on a defined, minimal medium (e.g., M9 for E. coli). A failure to grow indicates gaps in essential pathways.

- Conduct In Silico Growth Phenotyping (Essentiality Test):

- Simulate single gene knockout (using FBA) and compare predictions to known essential gene datasets (e.g., from Keio collection for E. coli).

- Calculate prediction accuracy metrics (Precision, Recall).

Table 2: Diagnostic Metrics for Model Evaluation

| Metric | Calculation/Description | Target Value for a "High-Quality" Model |

|---|---|---|

| Number of Reactions | Total metabolic reactions in the model. | Organism-specific, but should be consistent with similar models. |

| Number of Metabolites | Unique metabolic compounds. | Organism-specific. |

| Number of Unbalanced Reactions | Reactions not mass/charge balanced. | Minimize (aim for <5% of total reactions). |

| Growth Prediction Accuracy | (TP+TN)/(TP+TN+FP+FN) vs. experimental data. | >80-90% for model organisms. |

| Gene Essentiality Prediction (Precision) | TP/(TP+FP) for essential genes. | >0.75 |

| Gene Essentiality Prediction (Recall) | TP/(TP+FN) for essential genes. | >0.70 |

Phase III: Manual Curation and Refinement

Objective: Address gaps and inaccuracies identified in Phase II. Procedure:

- Gap Filling: Use computational tools (e.g.,

cobra.gapfillin CobraPy) to propose reactions that restore growth or functionality. Manually evaluate each proposed reaction against biochemical literature (KEGG, MetaCyc, BRENDA) before inclusion. - Biomass Reaction Curation: Ensure the biomass objective function accurately reflects the organism's macromolecular composition (DNA, RNA, protein, lipids, etc.) under your target growth condition. Update coefficients based on recent -omics data if available.

- Transport and Exchange Reaction Review: Verify that the model can uptake all nutrients present in your experimental medium and secrete known by-products. Add missing transport reactions.

- Gene-Protein-Reaction (GPR) Rule Verification: Ensure Boolean rules linking genes to reactions are correct and complete based on updated genome annotation.

- Addition of Thermodynamic Constraints (Optional but Recommended): Integrate estimated Gibbs free energy of formation (ΔfG') to constrain reaction directionality via thermodynamics-based flux analysis (TFA).

Phase IV: Validation and Finalization

Objective: Establish confidence in the model's predictive capability. Procedure:

- Multi-Condition Growth Validation: Test the model's ability to predict growth rates/secretion profiles across multiple carbon sources (e.g., glucose, glycerol, acetate) and compare with literature data.

- Phenotype Microarray Validation (if data exists): Compare predicted growth/no-growth phenotypes on a range of nutrients against high-throughput experimental data (e.g., Biolog plates).

- Production Capacity Test: Validate the model's prediction of maximum theoretical yield for a native metabolite (e.g., succinate in E. coli) against established theoretical values.

- Documentation: Create a comprehensive model report detailing all changes made during curation, sources of evidence, and validation results.

Visualization of the Workflow

Title: GEM Acquisition and Curation Protocol Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Computational Tools for GEM Curation

| Item Name | Category | Function/Application in Protocol |

|---|---|---|

| COBRA Toolbox (MATLAB) | Software | Primary suite for loading, analyzing, gap-filling, and simulating metabolic models. |

| cobrapy (Python) | Software | Python equivalent of COBRA Toolbox, enabling programmatic and reproducible model curation. |

| RAVEN Toolbox (MATLAB) | Software | Alternative toolbox with strong reconstruction, gap-filling, and integration of transcriptomics data. |

| MEMOTE | Software | Open-source test suite for standardized and automated quality assessment of genome-scale models. |

| KEGG Database | Database | Reference for metabolic pathways, enzyme functions, and compound information used in manual curation. |

| MetaCyc Database | Database | Curated database of experimentally elucidated metabolic pathways and enzymes. |

| Biolog Phenotype Microarray Data | Experimental Data | High-throughput experimental growth data used for model validation across many carbon/nitrogen sources. |

| Published Essential Gene Datasets | Experimental Data | (e.g., Keio collection for E. coli) used to benchmark gene essentiality predictions. |

| SBML File | Data Format | Standardized XML format for exchanging and storing computational models. Essential for interoperability. |

| Jupyter Notebook / R Markdown | Documentation | Environment to create reproducible, documented scripts for every step of the curation protocol. |

Application Notes

Defining environmental and genetic constraints is a critical second step in a Flux Balance Analysis (FBA) protocol for computational strain design. This step translates biological and experimental realities into mathematical boundaries for the genome-scale metabolic model (GEM). Proper constraint definition directly influences the predictive accuracy of FBA simulations and the feasibility of proposed strain designs for industrial bioproduction or drug target identification.

Environmental Constraints (Media Composition): These are defined by setting the upper and lower bounds for exchange reactions in the model, representing metabolite availability in the growth medium. Precise definition is essential for simulating different industrial conditions (e.g., minimal vs. rich media) or host environments in pathogen studies.

Genetic Constraints (Gene Knockouts): These are applied by constraining the flux through reactions catalyzed by the product of a knocked-out gene to zero. This simulates the phenotypic impact of deletions and is used to design strains with optimized product yield or to identify essential genes as potential drug targets.

Quantitative Data & Common Constraints

Table 1: Standard Constraints for Common Culture Media (mmol/gDW/hr)

| Medium Type | Glucose Uptake | Oxygen Uptake | Ammonia Uptake | Phosphate Uptake | Sulfate Uptake | Carbon Dioxide Exchange | Proton Exchange |

|---|---|---|---|---|---|---|---|

| Minimal (Aerobic) | -10.0 to -15.0 | -15.0 to -20.0 | -∞ (unlimited) | -∞ (unlimited) | -∞ (unlimited) | 0 to ∞ | -∞ to ∞ |

| Minimal (Anaerobic) | -10.0 to -15.0 | 0.0 | -∞ | -∞ | -∞ | 0 to ∞ | -∞ to ∞ |

| Rich (LB-like) | 0.0 | -18.0 to -20.0 | 0.0 | 0.0 | 0.0 | 0 to ∞ | -∞ to ∞ |

| Chemostat (D=0.1 h⁻¹) | -2.0 (calculated) | -∞ | -∞ | -∞ | -∞ | 0 to ∞ | -∞ to ∞ |

Note: Negative values denote uptake; positive values denote secretion. "∞" indicates an unconstrained bound, typically set to ±1000 in simulations.

Table 2: Typical Flux Bounds for Core Reaction Types

| Reaction Type | Default Lower Bound | Default Upper Bound | Constraint for Knockout |

|---|---|---|---|

| ATP Maintenance (ATPM) | 0.0 | ∞ | 0.0 to ∞ |

| Biomass Reaction | 0.0 | ∞ | 0.0 (lethal) or >0 (viable) |

| Internal Metabolic Reaction | -∞ (or -1000) | ∞ (or 1000) | -1000 to 1000 |

| Irreversible Internal Reaction | 0.0 | ∞ (or 1000) | 0.0 to 1000 |

| Exchange Reaction (Substrate) | -∞ (or -1000) | 0.0 | -1000 to 0.0 |

| Exchange Reaction (Product) | 0.0 | ∞ (or 1000) | 0.0 to 1000 |

| Transport Reaction | Variable | Variable | Set to 0 for transporter KO |

Experimental Protocols

Protocol 3.1: Defining Environmental Constraints in a COBRA Toolbox Workflow

Objective: To programmatically set the nutrient uptake rates for a genome-scale model (e.g., E. coli iJO1366) to simulate growth in a defined minimal medium.

Materials:

- Software: MATLAB or Python with COBRA Toolbox installed.

- Model: SBML-formatted genome-scale metabolic model.

Procedure:

- Load the Model:

- Identify Exchange Reactions:

Use

findExcRxns(model)to list all exchange reactions. Identify reaction IDs for key nutrients (e.g.,EX_glc__D_efor glucose). Close All Uptake: Initially, set all exchange reactions to only allow secretion (lower bound = 0) to create a "closed" system.

Open Specific Uptake Channels: Set bounds for allowed carbon, nitrogen, phosphorus, sulfur, and electron acceptor sources.

Set Product Secretion: Allow metabolic products (e.g., CO2) to be secreted.

Verify Constraints: Use

printUptakeBound(model)to display set uptake fluxes.

Protocol 3.2: Simulating Gene Knockouts and Assessing Essentiality

Objective: To simulate single-gene knockout phenotypes and classify genes as essential or non-essential under defined environmental conditions.

Materials:

- Software: Python with cobrapy package.

- Model: Constrained model from Protocol 3.1.

Procedure:

- Import and Prepare Model:

Perform Single-Gene Deletion Analysis: Use the

cobra.flux_analysismodule. Specify the reaction to optimize (typically biomass).Analyze Results and Classify Genes:

- Essential Gene: Biomass flux drops below a threshold (e.g., <5% of wild-type flux).

- Non-essential Gene: Biomass flux remains above the threshold.

Calculate wild-type growth rate first.

Output and Visualization: Create a table of essential genes and export results.

Visualizations

Diagram 1: Constraint Definition Workflow in FBA

Diagram 2: Impact of Constraints on Solution Space

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function/Application in Constraint Definition |

|---|---|

| COBRA Toolbox (MATLAB) | Primary software suite for constraint-based modeling. Functions like changeRxnBounds are used to implement constraints. |

| cobrapy (Python) | Python package for constraint-based reconstruction and analysis. Enables scripting of high-throughput knockout simulations. |

| SBML Model File | Systems Biology Markup Language file encoding the genome-scale metabolic network. The base structure to which constraints are applied. |

| Defined Media Recipes | Precisely formulated chemical compositions (e.g., M9, MOPS minimal medium). Used to determine numerical values for exchange reaction bounds. |

| Gene Deletion Mutant Library | Physical collection of strains (e.g., E. coli Keio collection). Used for experimental validation of in silico predicted knockout phenotypes. |

| Biolog Phenotype Microarray Plates | High-throughput assay plates with different carbon/nitrogen sources. Data informs which exchange reactions should be active in a given condition. |

| Flux Analysis Software (e.g., FVA) | Tools for Flux Variability Analysis. Run after constraint application to assess the range of possible fluxes through each reaction. |

1. Introduction & Thesis Context Within the systematic protocol for constraint-based metabolic modeling and Flux Balance Analysis (FBA) in strain design research, Step 3 is pivotal. It translates the qualitative biological goal of the engineered strain into a quantitative mathematical objective. The objective function defines what the in silico model will optimize, directly determining the predicted flux distribution. For a thesis exploring a comprehensive FBA protocol, this step bridges the gap between constructing a genome-scale model (GEM) and interpreting actionable metabolic insights for bioproduction or drug target identification.

2. Core Objective Functions: Theory & Application

The choice of objective function is hypothesis-driven and must reflect the physiological or engineering context. The table below summarizes the primary objective functions used in contemporary research.

Table 1: Primary Biological Objective Functions in FBA

| Objective Function | Mathematical Form | Primary Use Case | Key Considerations |

|---|---|---|---|

| Maximize Biomass Production | Maximize v_biomass |

Simulating native, growing cell states (e.g., wild-type bacteria, cancer cell proliferation). | Assumes growth is the primary evolutionary driver. Requires a carefully formulated biomass reaction. |

| Maximize Target Metabolite Yield | Maximize v_product (e.g., succinate, penicillin, ethanol) |

Strain design for bioproduction of chemicals, fuels, and pharmaceuticals. | May be coupled with a minimal growth constraint (v_biomass ≥ μ_min) to maintain cell viability. |

| Minimize Metabolic Adjustment (MOMA) | Minimize ∑(vi - vwt_i)² | Predicting flux distributions in knock-out mutants. | Assumes the mutant's flux state is closest to the wild-type's, a parsimonious response. |

| Maximize ATP Yield | Maximize v_ATPM |

Simulating energy metabolism under stress or non-growth conditions. | Useful for studying ATP-generating pathways and energy parasites. |

| Minimize Total Flux (pFBA) | Minimize ∑|v_i| | Identifying the most energetically efficient (parsimonious) flux distribution for a given objective. | Helps reduce flux redundancy and predict enzyme usage. |

3. Protocols for Implementing Objective Functions

Protocol 3.1: Formulating and Applying a Biomass Maximization Objective

- Purpose: To simulate maximum growth potential of an organism under specified environmental conditions.

- Materials: A curated genome-scale metabolic reconstruction (e.g., in SBML format), FBA software (COBRApy, RAVEN Toolbox).

- Procedure:

- Load the metabolic model into your computational environment.

- Verify the presence and accuracy of the biomass objective function (BOF) reaction. This reaction should incorporate all essential macromolecular precursors (amino acids, nucleotides, lipids, cofactors) in their experimentally determined proportions.

- Set the BOF reaction as the objective to maximize:

model.objective = 'BIOMASS_reaction_ID'. - Apply relevant medium constraints (from Step 2 of the thesis protocol).

- Solve the linear programming problem:

solution = optimize(model). - Extract and analyze the growth rate (

solution.objective_value) and associated flux distribution.

- Validation: Compare the predicted growth rate with experimentally measured growth rates in the same medium. Perform sensitivity analysis on critical biomass precursors.

Protocol 3.2: Coupling Growth with Product Synthesis for Strain Design

- Purpose: To predict metabolic states that maximize the production of a target metabolite while maintaining cell viability.

- Materials: Engineered metabolic model (with added/exchanged reactions for production), FBA software.

- Procedure:

- Identify the exchange reaction for the target metabolite (e.g.,

EX_succ_e). - Define a two-tiered objective: a) Primary: Maximize the target metabolite exchange flux. b) Constraint: Impose a lower bound on biomass flux to ensure viability (e.g.,

model.reactions.BIOMASS.lower_bound = 0.05*h_µ_max). - Alternatively, use a bi-level optimization approach such as OptKnock, implemented via the

cameoorCOBRApypackages:

- Identify the exchange reaction for the target metabolite (e.g.,

4. The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Tools for Implementing FBA Objective Functions

| Item / Solution | Function & Application |

|---|---|

| COBRApy (Python) | A primary software toolbox for constraint-based modeling. Used to load models, set objective functions, run FBA, and perform strain design algorithms. |

| RAVEN Toolbox (MATLAB) | An alternative suite for model reconstruction, curation, and simulation, widely used for yeast and mammalian cell models. |

| cameo (Python) | A high-level strain design and modeling platform built on COBRApy. Provides user-friendly access to OptKnock, OptGene, and other advanced algorithms. |

| Commercial GEMs (e.g., from BioModels, Path2Models) | Pre-constructed, often manually curated models for common chassis organisms (E. coli, S. cerevisiae, CHO cells). Provide a starting point with validated biomass functions. |

| SBML Format | The standard Systems Biology Markup Language for model exchange. Ensures objective functions and constraints are portable between software tools. |

| Linear Programming Solvers (e.g., GLPK, CPLEX, Gurobi) | The computational engines that solve the optimization problem. CPLEX and Gurobi are commercial and offer speed for large models; GLPK is open-source. |

5. Visualizations

Title: Objective Function Selection Drives FBA Prediction

Title: Metabolic Flux Partitioning Under Different Objectives

Flux Balance Analysis (FBA) is the computational cornerstone of modern metabolic engineering. Following model reconstruction and curation, running simulations is where predictive hypotheses are tested. This stage involves selecting appropriate numerical solvers, software environments, and simulation platforms to calculate flux distributions, predict growth phenotypes, and identify gene knockout targets. Within a thesis on FBA protocol for strain design, this step translates a static metabolic network into dynamic, actionable predictions for strain optimization.

Core Solvers: The Computational Engines

Solvers are the numerical optimization backends that perform the linear programming (LP) and mixed-integer linear programming (MILP) calculations required by FBA and its advanced applications.

Table 1: Primary Numerical Solvers for FBA Simulations

| Solver Name | Type | Key Features | Typical Use Case in Strain Design | License |

|---|---|---|---|---|

| Gurobi | LP, QP, MILP, MIQP | Extreme speed, robust performance, excellent support | Large-scale gene knockout optimization (e.g., OptKnock) | Commercial |

| CPLEX | LP, QP, MILP, MIQP | High performance, reliable for complex MILP problems | Metabolic engineering with complex constraints | Commercial |

| GLPK | LP, MILP | Open-source, standard LP solver | Basic FBA simulations, educational use | Open Source (GPL) |

| SCIP | MILP, MINLP | Leading open-source non-commercial solver for constraints | OptKnock when commercial solvers are unavailable | Open Source |

| COIN-OR CLP/CBC | LP, MILP | Open-source, integrated with many toolboxes | Medium-scale problems in open-source workflows | Open Source (EPL) |

Software Platforms & Programming Environments

Researchers typically interact with solvers through higher-level software toolboxes that provide an abstraction layer for model manipulation and simulation.

A. COBRA Toolbox

The COBRA (Constraint-Based Reconstruction and Analysis) Toolbox is the most established suite for MATLAB and, via its Python port, for that language. It provides a comprehensive set of functions for running FBA, Flux Variability Analysis (FVA), and strain design algorithms.

Protocol 1: Running FBA and FVA for Target Metabolite Production Using COBRApy Objective: Identify maximum theoretical yield of a target metabolite and assess flux flexibility under optimal production conditions.

- Prerequisites: Install COBRApy (

pip install cobra). Have a genome-scale metabolic model (e.g.,iML1515.json) loaded. Set Model Objective: Define biomass reaction as the primary objective for growth simulation.

Run FBA for Growth: Calculate the maximal growth rate.

Modify Objective for Production: Change the objective to a target metabolite exchange reaction (e.g., succinate).

Run Flux Variability Analysis (FVA): Determine the range of possible fluxes for all reactions at optimal production (e.g., at 90% of max production).

Analyze Results: Identify reactions with fixed (non-flexible) fluxes as potential metabolic engineering targets.

B. Cameo

Cameo is a high-level Python framework built on top of COBRApy, specifically designed for metabolic engineering with a more user-friendly API and advanced strain design methods.

Protocol 2: Performing OptKnock Strain Design Using Cameo Objective: Use a bi-level optimization (OptKnock) to identify gene knockout strategies that maximize product yield while coupling it to growth.

- Prerequisites: Install cameo (

pip install cameo). Load a model. Define Target and Simulation Conditions:

Configure and Run OptKnock:

Interpret Results:

C. MATLAB vs. Python: A Comparison

Table 2: Comparison of Primary FBA Simulation Environments

| Feature | MATLAB + COBRA Toolbox | Python + COBRApy/Cameo |

|---|---|---|

| Primary Audience | Traditional systems biology, academia with licenses | Growing community, bioinformatics, open-source advocates |

| Strengths | Mature, extensive algorithm library, excellent documentation, tight integration with SimBiology | Free, versatile, easier integration with ML/AI libraries, modern development tools |

| Weaknesses | Requires expensive commercial license | Can have steeper integration/configuration learning curves |

| Typical Workflow | GUI available, but primarily script-based analysis | Script-based and notebook (Jupyter) driven analysis |

| Solver Integration | Seamless with Gurobi, CPLEX; GLPK included | Requires separate installation of solvers (e.g., pip install gurobipy) |

Visualization of the Simulation Workflow

Title: Workflow for Running FBA Simulations in Strain Design

The Scientist's Toolkit: Essential Research Reagents & Software

Table 3: Key Resources for Running FBA Simulations

| Item | Category | Function in Simulation Protocol |

|---|---|---|

| Gurobi Optimizer | Commercial Solver | High-performance solver for fast computation of LP/MILP problems in large models. |

| COBRA Toolbox for MATLAB | Software Library | Provides core functions for model loading, constraint manipulation, FBA, and pathway analysis. |

| COBRApy & Cameo | Python Libraries | Open-source Python alternatives for COBRA, with Cameo specializing in user-friendly strain design. |

| A Standard Laptop/Workstation (16GB+ RAM) | Hardware | Sufficient for most GSMM simulations; very large models or many parallel simulations may require HPC. |

| Jupyter Notebook / MATLAB Live Script | Interactive Environment | Enables reproducible, documented, and interactive exploration of simulation results. |

| SBML Model File (.xml or .json) | Data Input | The standardized, curated metabolic model that is the input for all simulations. |

| Pandas & NumPy (Python) / Statistics Toolbox (MATLAB) | Data Analysis Libraries | For post-processing, statistical analysis, and visualization of flux results. |

Within the broader thesis on Flux Balance Analysis (FBA) protocols for microbial strain design, the interpretation of simulation results is the critical translational step. This phase moves beyond computational predictions to actionable biological insight. The objective is to parse FBA outputs—including optimal growth rates, flux distributions, and shadow prices—to pinpoint metabolic reactions, corresponding genes, and genetic or environmental intervention strategies that enhance the production of a target compound (e.g., a biofuel or therapeutic precursor) while maintaining organismal viability.

Key Quantitative Outputs from FBA and Their Interpretation

FBA simulations generate several key metrics. The following table summarizes these outputs and their relevance for identifying intervention targets.

Table 1: Core FBA Outputs and Their Interpretive Significance

| Output Metric | Typical Range/Value | Interpretation for Strain Design | Implied Intervention |

|---|---|---|---|

| Objective Function (e.g., Growth Rate, μ) | 0 - ~1.0 h⁻¹ | Maximized rate of biomass production under constraints. A decrease upon inserting a production pathway indicates a trade-off. | Identify and relieve bottlenecks limiting co-optimal growth and product synthesis. |

| Target Product Flux (v_product) | mmol/gDW/h | The simulated production rate of the desired compound (e.g., succinate, lycopene). | Reactions carrying high flux toward the product are candidate amplification targets. |

| Flux Variability Range | Min/Max flux values | The permissible range a reaction flux can assume while achieving optimal objective. Low variability indicates a rigid, often essential, pathway. | Reactions with low variability and high flux are potential knock-out targets only if non-essential. Reactions with high variability offer flexibility. |

| Shadow Price (of a metabolite) | Negative, Zero, or Positive value | The change in the objective function per unit change in the availability of a metabolite. A highly negative price indicates the metabolite is severely limiting growth. | Metabolites with highly negative shadow prices are prime candidates for supplementation or pathway upregulation to enhance flux. |

| Reduced Cost (of a reaction flux) | Negative, Zero, or Positive value | The amount by which the objective would improve if a constrained reaction's bound was relaxed by one unit. Non-zero values indicate the reaction is limiting. | Reactions with large magnitude reduced costs are key constraints; their enzymatic genes are prime targets for overexpression or deregulation. |

Protocol: From FBA Results to Candidate Gene List

This protocol details the steps to transition from raw FBA simulation data to a shortlist of genes for genetic engineering.

Protocol 3.1: Systematic Identification of Key Reactions and Genes

Objective: To identify and prioritize gene targets for knockout, upregulation, or downregulation based on FBA flux distributions and sensitivity analysis. Materials: FBA model (e.g., in SBML format), simulation results (flux vectors, shadow prices), genome-scale reconstruction gene-reaction rules database (e.g., BIGG Models), bioinformatics software (COBRA Toolbox for MATLAB/Python, or similar). Procedure:

- Perform Flux Parsing: Run FBA with the objective of maximizing target product synthesis, often with a constrained minimal growth rate (e.g., 10% of wild-type). Export the resultant flux distribution (

v_opt). - Identify High-Impact Reactions:

- High-Flux Reactions: Sort absolute flux values in

v_opt. Identify the top 10-20 reactions carrying the highest flux in the product synthesis pathway and central metabolism. - Sensitivity Analysis: Perform in silico gene knockout simulations (e.g., using FBA with minimization of metabolic adjustment, MOMA). Rank genes by the simulated impact on product yield when deleted.

- Flux Variability Analysis (FVA): For the optimal objective, calculate the min/max flux of each reaction. Reactions with a small range (e.g., max - min < 0.1 mmol/gDW/h) and high flux are potential bottlenecks.

- High-Flux Reactions: Sort absolute flux values in

- Map Reactions to Genes: Using the model's

grRules(gene-protein-reaction rules), map each prioritized reaction to its encoding gene(s). Note Boolean relationships (AND for complexes, OR for isozymes). - Contextualize with Shadow Prices/Reduced Costs: Cross-reference the gene list with metabolites exhibiting highly negative shadow prices in the production simulation. Prioritize genes involved in the synthesis or transport of those metabolites.

- Generate Prioritized Candidate List: Create a final table ranking candidate genes. Include columns for: Gene ID, Associated Reaction(s), Flux Value, Knockout Impact (Predicted % Yield Change), Proposed Intervention (Knockout, Attenuate, Overexpress), and Rationale.

Experimental Validation Workflow

Computational predictions require empirical testing. This workflow integrates in silico predictions with laboratory experiments in an iterative design-build-test-learn (DBTL) cycle.

The Scientist's Toolkit: Key Reagents and Materials

Table 2: Essential Research Reagent Solutions for Strain Design & Validation

| Reagent/Material | Function in Protocol | Example/Supplier Note |

|---|---|---|

| Genome-Scale Metabolic Model | In silico platform for FBA simulations and target prediction. | Curated models from BIGG Database or MetaNetX. Used with COBRApy. |

| COBRA Toolbox | Software suite for constraint-based modeling and analysis. | Implemented in MATLAB or Python (COBRApy). Essential for running FBA, FVA, and knockout simulations. |

| CRISPR-Cas9 Toolkit | Enables precise gene knockouts, knockdowns, and integrations in the host strain. | Includes Cas9 expression plasmid, gRNA vectors, and DNA repair templates for the target organism (e.g., E. coli, S. cerevisiae). |

| Promoter & RBS Library | For fine-tuning gene expression levels of targeted pathways. | Collections of characterized promoters and ribosome binding sites of varying strengths for predictable metabolic engineering. |

| Defined Minimal Medium | Essential for controlled fermentation experiments to correlate model predictions (nutrient constraints) with growth and product yield. | Formulations like M9 (bacteria) or SM (yeast) with precise carbon source and supplementation as per simulation insights. |

| LC-MS/MS System | Quantifies extracellular and intracellular metabolite concentrations (fluxomics/metabolomics) to validate flux predictions. | Critical for measuring target product titer, yield, and byproduct secretion. |

| qPCR or RNA-Seq Reagents | Validates transcriptional changes in engineered strains (e.g., confirmation of gene overexpression or knockdown). | Provides a layer of mechanistic insight between genetic intervention and observed phenotypic changes. |

Protocol:In VivoValidation of Predicted Gene Knockouts

Objective: To experimentally test the impact of a computationally-predicted gene knockout on microbial growth and product formation. Materials: Wild-type microbial strain, CRISPR-Cas9 plasmids or lambda Red recombinering system for gene deletion, primers for gene knockout and verification, selective agar plates, defined minimal medium, bioreactor or deep-well plates, LC-MS or HPLC for product quantification. Procedure:

- Strain Construction: Design gRNAs or homology arms for the target gene. Transform the editing system into the host strain. Select clones on appropriate antibiotic plates.

- Genotypic Validation: Confirm the knockout via colony PCR using primers flanking the deletion site and Sanger sequencing of the amplicon.

- Phenotypic Screening: Inoculate confirmed knockout and wild-type control strains in defined minimal medium in biological triplicate. Use a microplate reader to monitor optical density (OD600) over 24-48 hours to assess growth impact.

- Product Titer Analysis: At stationary phase, centrifuge cultures. Filter the supernatant and analyze via HPLC or LC-MS to quantify the target product and key byproducts (e.g., acetate, lactate). Compare yields between knockout and wild-type.

- Data Integration: Compare experimental growth rate and product yield with FBA predictions for the corresponding in silico knockout. Significant discrepancies may indicate model gaps (e.g., missing regulation) and inform model refinement.

Application Notes: Metabolic Engineering for Precursor Augmentation

Within the broader thesis framework employing Flux Balance Analysis (FBA) for strain design, a critical practical application is the development of microbial production hosts with enhanced supply of polyketide precursors. Polyketides, a diverse class of natural products with potent pharmaceutical activities (e.g., antibiotics, statins, antifungals), are biosynthesized from simple acyl-CoA precursors like malonyl-CoA and methylmalonyl-CoA. Native host metabolism often inadequately supplies these precursors, creating a bottleneck identified through in silico FBA simulations.

The primary engineering targets are:

- Acetyl-CoA carboxylase (ACC): Catalyzes the ATP-dependent carboxylation of acetyl-CoA to malonyl-CoA.

- Propionyl-CoA carboxylase (PCC): Catalyzes the carboxylation of propionyl-CoA to (S)-methylmalonyl-CoA.

- Precursor competing pathways: Pathways that divert carbon flux away from acetyl-CoA and propionyl-CoA pools.

Recent advances (2023-2024) highlight the integration of FBA with kinetic modeling and omics data to pinpoint non-intuitive gene knockout/upregulation targets that maximize precursor yield while maintaining cellular robustness.

Table 1: Key Precursor Pathways and Recent Engineering Targets

| Precursor | Primary Biosynthetic Route | Key Enzymes | Recent Engineering Strategy (2023-2024) | Reported Yield Increase |

|---|---|---|---|---|

| Malonyl-CoA | Acetyl-CoA → Malonyl-CoA | ACC complex (AccA, AccB, AccC, AccD) | Heterologous expression of Corynebacterium glutamicum ACC with modified biotin ligase (BirA) in E. coli. | 2.8-fold vs. native |

| (S)-Methylmalonyl-CoA | Propionyl-CoA → (S)-Methylmalonyl-CoA | PCC complex (PccA, PccB) | CRISPRi-mediated downregulation of succinate dehydrogenase (SdhA) to reduce TCA cycle drain on succinyl-CoA, a precursor to propionyl-CoA. | 1.9-fold vs. control |

| Acetyl-CoA Pool | Glycolysis → Pyruvate → Acetyl-CoA | Pyruvate dehydrogenase (PDH), ATP-citrate lyase (ACL) | Expression of heterologous ACL from Yarrowia lipolytica in cytosol of S. cerevisiae, bypassing PDH complex. | 3.1-fold cytosolic acetyl-CoA |

Table 2: Quantitative Impact of Common Gene Manipulations on Precursor Flux (FBA Predictions vs. Experimental)

| Target Gene | Modification | Host | FBA-Predicted Δ Flux (mmol/gDCW/h) | Experimentally Measured Δ Flux | Polyketide Titer Outcome |

|---|---|---|---|---|---|

| pta (phosphotransacetylase) | Knockout | E. coli | +0.18 (Malonyl-CoA) | +0.15 ± 0.03 | 110% increase for 6-MSA |

| accBC (ACC subunits) | Plasmid-based overexpression | Streptomyces coelicolor | +0.32 (Malonyl-CoA) | +0.28 ± 0.05 | 75% increase for actinorhodin |

| sucCD (succinyl-CoA synthetase) | Knockdown (CRISPRi) | Pseudomonas putida | +0.12 (Methylmalonyl-CoA) | +0.09 ± 0.02 | Data not yet published |

Detailed Experimental Protocols

Protocol 2.1: FBA-Guided Identification of Precursor-Limiting Reactions

This protocol is integral to the thesis methodology for initial strain design.

Materials: Genome-scale metabolic model (GEM) of host organism (e.g., iML1515 for E. coli), constraint-based modeling software (COBRApy or MATLAB COBRA Toolbox).

Procedure:

- Load and Condition Model: Import the GEM. Set constraints to reflect your experimental conditions (e.g., glucose M9 minimal medium, aerobic growth).

- Define Objective: Set biomass reaction as the objective for initial simulation to establish wild-type flux distribution.

- Perform Flux Variability Analysis (FVA): For the wild-type model, calculate the minimum and maximum possible flux through the malonyl-CoA and methylmalonyl-CoA synthesis reactions (e.g.,

MACCOASfor malonyl-CoA in E. coli models). - Simulate Precursor Overproduction: Add a demand reaction for the target precursor (e.g.,

DM_malcoa) to the model. Progressively increase its lower bound and simulate growth. Plot growth rate vs. precursor production rate to identify the theoretical trade-off. - Gene Essentiality and Knockout Screening: Use the

singleGeneDeletionfunction. Identify gene knockouts that minimize the reduction in growth while maximizing the in silico flux through the precursor demand reaction. - Output: Generate a ranked list of gene knockout targets. Prioritize those involving competing pathways (e.g., fatty acid biosynthesis) or redirecting flux from central metabolism.

Protocol 2.2: Implementing CRISPRi-MediatedsucCDKnockdown for Methylmalonyl-CoA Enhancement inP. putida

Materials: P. putida KT2440 strain, pSEVA231-dCas9 plasmid, sgRNA expression plasmid targeting sucCD sequence, LB and M9 media, antibiotics (gentamicin, kanamycin), RT-qPCR reagents, LC-MS/MS for methylmalonyl-CoA quantification.

Procedure:

- sgRNA Cloning: Design and synthesize oligos for the sucCD target site (20 bp NGG PAM). Anneal and ligate into the BsaI site of the sgRNA expression plasmid. Transform into E. coli DH5α and sequence-verify.

- Strain Construction: Co-transform the dCas9 plasmid and the verified sgRNA plasmid into P. putida via electroporation. Select on plates with gentamicin and kanamycin.

- Validation of Knockdown:

- Growth Phenotype: Inoculate engineered and control strains in M9 + 20 mM succinate. Monitor OD600 over 24h. Expect a slight growth defect due to TCA cycle perturbation.

- Transcript Level: Harvest cells at mid-log. Extract RNA, synthesize cDNA, perform RT-qPCR for sucCD using housekeeping gene (e.g., rpoD) for normalization.

- Precursor Quantification: Quench metabolism rapidly, perform metabolite extraction. Analyze (S)-methylmalonyl-CoA levels using LC-MS/MS with a stable isotope-labeled internal standard.

Mandatory Visualizations

Diagram 1: Engineered Pathways for Polyketide Precursor Supply

Diagram 2: FBA Workflow for Strain Design

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in Precursor Engineering | Example Product/Catalog |

|---|---|---|

| Genome-Scale Metabolic Model (GEM) | In silico platform for FBA to predict flux distributions and identify engineering targets. | BiGG Models (e.g., iML1515, iJN1463). CarveMe for model reconstruction. |

| CRISPRi/dCas9 System | Enables tunable, reversible gene knockdown without knockout; crucial for testing essential gene targets. | pDawn (blue-light inducible) or pSEVA series (constitutive) dCas9 plasmids. |

| LC-MS/MS Metabolite Standards | Absolute quantification of intracellular precursor pools (malonyl-CoA, methylmalonyl-CoA). | 13C3-labeled Malonyl-CoA & (S)-Methylmalonyl-CoA (Sigma-Aldrich, Cambridge Isotopes). |

| Acetyl-CoA Carboxylase (ACC) Enzyme Assay Kit | Measures enzymatic activity of ACC in cell lysates to confirm functional overexpression. | Colorimetric/Fluorometric ACC Activity Assay Kit (Abcam, BioVision). |

| M9 Minimal Media (Custom Formulation) | Defined medium for consistent metabolic flux analysis; allows control of carbon source (e.g., propionate for methylmalonyl-CoA). | Prepared in-house or commercial base (e.g., Teknova M9 Salts). |

| COBRA Software Toolbox | Primary computational environment for performing FBA, FVA, and gene deletion simulations. | COBRApy (Python) or COBRA Toolbox (MATLAB). |

Advanced FBA: Troubleshooting Common Pitfalls and Optimizing Design Predictions

Diagnosing and Resolving Infeasible FBA Solutions and Unrealistic Flux Distributions

1. Introduction Within a broader thesis on developing robust Flux Balance Analysis (FBA) protocols for metabolic engineering and strain design, a critical challenge is the generation of infeasible solutions or unrealistic flux distributions. These outputs undermine model predictions and obstruct rational design. This document provides application notes and protocols to systematically diagnose root causes and implement corrective measures.