How CataPro's AI-Powered Kinetic Prediction Accelerates Enzyme Engineering for Drug Discovery

This article explores the transformative role of AI-assisted enzyme engineering, focusing on the CataPro platform for kinetic parameter prediction (kcat, KM, kcat/KM).

How CataPro's AI-Powered Kinetic Prediction Accelerates Enzyme Engineering for Drug Discovery

Abstract

This article explores the transformative role of AI-assisted enzyme engineering, focusing on the CataPro platform for kinetic parameter prediction (kcat, KM, kcat/KM). Targeted at researchers and drug development professionals, we provide a comprehensive guide covering foundational concepts, practical workflows for engineering enzymes like PETases and P450s, strategies to overcome common pitfalls in model training and data scarcity, and a critical validation against traditional methods. The analysis highlights how integrating CataPro's predictions into directed evolution pipelines drastically reduces experimental screening burdens, enabling the rapid development of enzymes with enhanced activity, stability, and novel functions for biomedical applications.

What is AI-Assisted Enzyme Engineering? Demystifying CataPro and Kinetic Prediction

Application Notes

Traditional enzyme engineering remains a cornerstone of biocatalysis and therapeutic development but is defined by resource-intensive, low-throughput workflows. Within the thesis on AI-assisted enzyme engineering, CataPro’s kinetic parameter prediction emerges as a critical tool to triage and prioritize variants, mitigating the high costs and long timelines of traditional methods.

- Table 1: Comparative Analysis of Traditional vs. AI-Assisted Enzyme Engineering Workflows

| Parameter | Traditional Directed Evolution | AI-Guided Engineering with CataPro |

|---|---|---|

| Library Size | 10^4 – 10^6 variants per round | 10^1 – 10^3 in silico designed variants |

| Primary Screening Throughput | ~10^3 – 10^4 variants/day (activity-based) | ~10^5 – 10^6 variants/day (in silico prediction) |

| Key Kinetic Data (kcat, KM) | Late-stage, low-throughput (< 10^2 variants) | Early-stage, high-throughput prediction for all designs |

| Typical Cycle Time | 3 – 6 months (build, screen, characterize) | 1 – 4 weeks (design, predict, build focused set) |

| Primary Resource Bottleneck | Expression, purification, and low-throughput assays | Computational power and training data quality |

- Table 2: Quantitative Impact of Experimental Bottlenecks in Traditional Workflows (Representative Data)

| Experimental Step | Typical Duration | Approximate Cost per 100 Variants (Reagents & Consumables) | Success Rate/Throughput |

|---|---|---|---|

| Site-Saturation Mutagenesis Library Construction | 1-2 weeks | $1,500 - $3,000 | 90-95% (cloning efficiency) |

| Protein Expression & Purification (Microscale) | 1 week | $2,000 - $5,000 | 60-80% (soluble expression) |

| Initial Activity Screen (e.g., Colorimetric) | 3-5 days | $500 - $1,500 | ~10^3 variants/day |

| Kinetic Characterization (Steady-State) | 2-4 weeks | $3,000 - $8,000 | 1-5 variants/week |

Detailed Experimental Protocols

Protocol 1: Traditional Workflow for Kinetic Characterization of Enzyme Variants

Title: Steady-State Kinetics Assay for Recombinant Enzyme Variants.

Objective: To determine the Michaelis constant (Kₘ) and turnover number (kcat) for purified wild-type and mutant enzymes.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Enzyme Preparation: Dilute purified enzyme stocks into Assay Buffer (without substrate) to a working concentration. Keep on ice.

- Substrate Dilution Series: Prepare at least eight substrate concentrations spanning 0.2Kₘ to 5Kₘ in Assay Buffer.

- Assay Plate Setup: In a 96-well UV-transparent plate, add 198 µL of each substrate concentration per well, in duplicate.

- Reaction Initiation: Rapidly add 2 µL of diluted enzyme to each well using a multichannel pipette, mixing thoroughly. Final reaction volume: 200 µL.

- Initial Rate Measurement: Immediately monitor the change in absorbance (or fluorescence) at the appropriate wavelength for 1-3 minutes using a plate reader maintained at 30°C.

- Data Analysis: Calculate initial velocity (v₀) for each substrate concentration [S] from the linear slope of product formation vs. time. Fit v₀ vs. [S] data to the Michaelis-Menten equation (v₀ = (Vₘₐₓ[S])/(Kₘ + [S])) using non-linear regression software (e.g., GraphPad Prism). Calculate kcat = Vₘₐₓ / [Enzyme].

Protocol 2: Integrating CataPro Predictions into a Focused Validation Pipeline

Title: Targeted Validation of AI-Predicted Enzyme Variants.

Objective: To experimentally validate the catalytic efficiency (kcat/Kₘ) of a small set of enzyme variants pre-screened by CataPro's kinetic parameter predictions.

Procedure:

- AI-Guided Design: Input wild-type sequence and structural data into CataPro. Generate predictions for kcat and Kₘ for all possible single-point mutants in the active site region.

- Variant Prioritization: Select 20-50 variants for experimental testing based on:

- Predicted improved kcat/Kₘ (>2-fold over WT).

- Clustering of promising mutations to inform combinatorial designs.

- Structural plausibility (no severe steric clashes).

- Focused Library Construction: Use site-directed mutagenesis (e.g., KLD method) to construct only the prioritized variants.

- Express & Purify: Follow standard protocols (as above) for the focused variant set.

- Validation Assay: Perform kinetic characterization (Protocol 1) on the purified variants.

- Model Feedback: Input experimental kcat/Kₘ results back into CataPro to refine and improve the AI prediction model for subsequent engineering cycles.

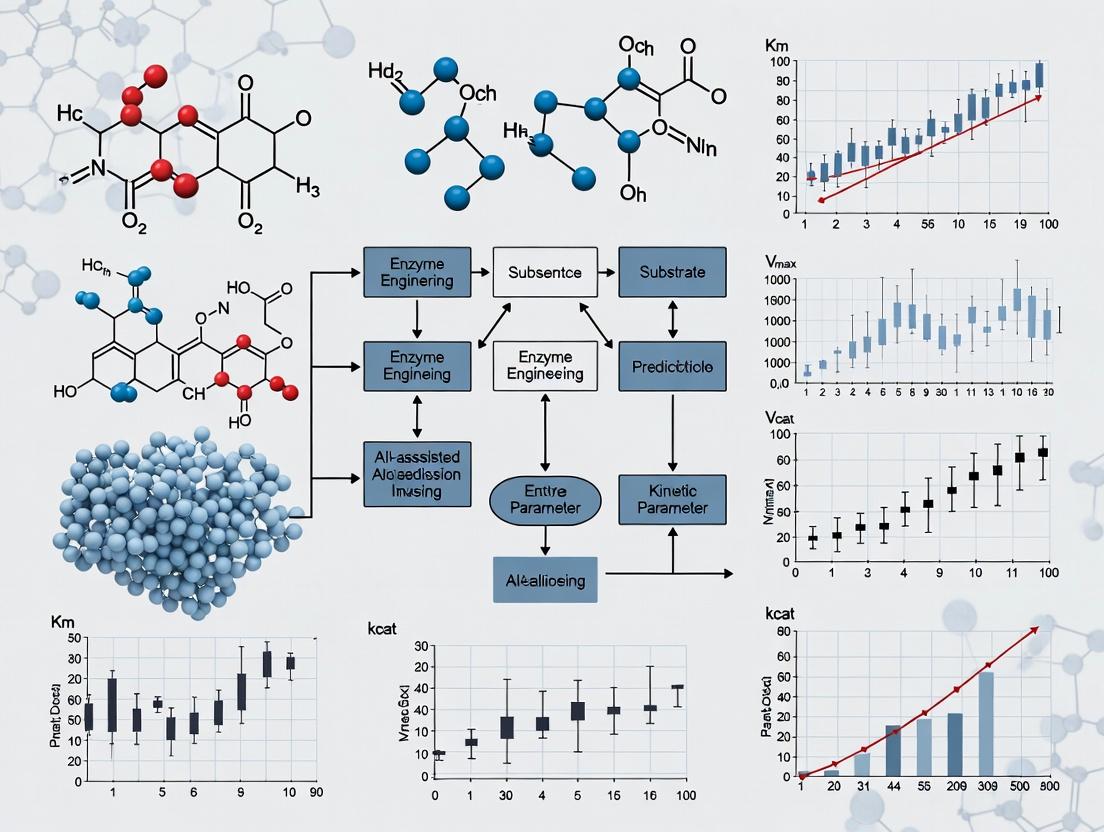

Visualizations

Diagram Title: The Traditional Enzyme Engineering Cycle

Diagram Title: AI-Assisted Engineering with CataPro

The Scientist's Toolkit: Key Research Reagent Solutions

- KLD Enzyme Mix (NEB): A post-PCR enzyme mix (Kinase, Ligase, DpnI) used in site-directed mutagenesis to rapidly and efficiently generate point mutations in plasmid DNA.

- Ni-NTA Superflow Resin (Qiagen): Immobilized metal affinity chromatography (IMAC) resin for high-yield purification of polyhistidine (His-tag)-tagged recombinant proteins.

- SuperSignal West Pico PLUS Chemiluminescent Substrate (Thermo Fisher): A sensitive HRP substrate used in western blotting to confirm protein expression and purity.

- pET Expression Vectors (Novagen/Merck): A widely used series of E. coli expression plasmids featuring a T7 lac promoter for tightly controlled, high-level protein production.

- Chromogenic/Flurogenic Substrate Analogs (e.g., Sigma, Tocris): Synthetic substrates that yield a measurable color or fluorescence change upon enzyme turnover, enabling high-throughput activity screens.

- Precision Plus Protein Kaleidoscope Standards (Bio-Rad): A set of prestained molecular weight markers for accurate size determination of proteins via SDS-PAGE analysis.

Within the context of AI-assisted enzyme engineering, precise characterization of enzyme kinetics is paramount. The kinetic parameters kcat, KM, and their derived ratio kcat/KM are the fundamental quantitative descriptors of enzyme function. In platforms like CataPro, these parameters are not only experimental outputs but also critical training features and predictive targets for machine learning models. This note details the biochemical definitions, experimental determination, and practical significance of these core parameters for researchers leveraging computational tools in enzyme design and optimization.

Core Parameter Definitions & Significance

kcat (Turnover Number): The maximum number of substrate molecules converted to product per enzyme molecule per unit time (typically s⁻¹). It defines the intrinsic catalytic power of a fully saturated enzyme.

KM (Michaelis Constant): The substrate concentration at which the reaction rate is half of Vmax. It is inversely related to the enzyme's apparent affinity for the substrate under steady-state conditions.

Catalytic Efficiency (kcat/KM): A pseudo-second-order rate constant (M⁻¹s⁻¹) describing the enzyme's performance at low, non-saturating substrate concentrations. It represents the enzyme's ability to both bind and convert substrate.

Table 1: Typical Ranges and Interpretation of Kinetic Parameters

| Parameter | Typical Range | Interpretation in AI-Assisted Engineering Context |

|---|---|---|

| kcat | 0.01 - 10⁶ s⁻¹ | Target for optimization in industrial biocatalysis. Higher kcat often desired. AI models predict impact of mutations on transition state stabilization. |

| KM | 1 µM - 100 mM | Target for tuning based on application. Low KM desirable for scarce substrates; engineered KM can match physiological or process conditions. |

| kcat/KM | 10¹ - 10⁸ M⁻¹s⁻¹ | Primary fitness metric for enzyme evolution. Directly relates to in vivo efficacy. CataPro uses this as a key predictive output for variant ranking. |

| Specificity Constant | (kcat/KM)A / (kcat/KM)B | Predictor of substrate selectivity. Critical for drug design (e.g., protease inhibitors) and pathway engineering to avoid cross-talk. |

Key Experimental Protocols

Protocol 1: Determining kcat and KM via Initial Velocity Measurements

Objective: To obtain Michaelis-Menten parameters for a wild-type or engineered enzyme variant.

Research Reagent Solutions:

- Purified Enzyme: Recombinantly expressed and purified target enzyme. Function: The catalyst under study.

- Substrate Solution(s): Prepared in reaction buffer at a stock concentration >> expected KM. Function: The reactant whose conversion is measured.

- Assay Buffer: Optimized for pH, ionic strength, and cofactors. Function: Provides physiologically relevant reaction conditions.

- Detection Reagent: e.g., chromogenic/fluorogenic coupling enzymes, NADH, or direct product probe. Function: Enables quantifiable signal proportional to product formation.

- Stop Solution: (If needed) e.g., acid, base, or inhibitor. Function: Halts reaction at precise timepoints for fixed-time assays.

Methodology:

- Prepare a dilution series of substrate covering a range from ~0.2KM to 5KM (ideally determined from a preliminary experiment).

- Pre-incubate enzyme and substrate separately in a thermostatted plate reader or cuvette holder (e.g., 30°C).

- Initiate reactions by mixing enzyme with substrate. The final enzyme concentration should be << KM to maintain steady-state conditions (typically nM to pM range).

- Monitor the linear increase of product (or decrease of substrate) over time (initial velocity, v0) for each substrate concentration [S].

- Fit the collected data (v0 vs. [S]) to the Michaelis-Menten equation using non-linear regression software:

v0 = (Vmax * [S]) / (KM + [S]) - Calculate kcat:

kcat = Vmax / [E]total, where [E]total is the molar concentration of active enzyme.

Protocol 2: High-Throughput Screening for Catalytic Efficiency (kcat/KM)

Objective: To rapidly rank engineered enzyme variant libraries for catalytic efficiency, enabling prioritization for full kinetic analysis.

Research Reagent Solutions:

- Cell Lysates/Variant Library: Microtiter plates containing expressed variant enzymes. Function: Source of enzyme diversity.

- Single Low-Substrate Concentration Solution: [S] << KM (anticipated). Function: Ensines reaction velocity is approximately proportional to kcat/KM.

- Universal Assay Master Mix: Contains buffer, cofactors, and detection system. Function: Standardizes conditions across all variants.

- Reference Standards: Wild-type enzyme and negative control (e.g., blank, inactive mutant). Function: Enables normalization and quality control.

Methodology:

- Normalize variant expression levels (e.g., via fluorescence, immunoassay, or active site titration) to account for differences in protein concentration/folding.

- Dispense standardized assay master mix containing a single, low concentration of substrate into all wells of a microtiter plate.

- Initiate reaction by adding normalized lysate.

- Measure initial velocities (v0) for all variants under identical conditions.

- Since at [S] << KM, v0 ≈ (kcat/KM) * [E] * [S], the measured v0 (when normalized for [E]) is directly proportional to kcat/KM.

- Rank variants based on normalized activity. Top hits are selected for thorough kinetic characterization via Protocol 1.

Visualization of Concepts & Workflows

Diagram Title: AI-Driven Enzyme Engineering Cycle with Kinetic Screening

Diagram Title: Derivation of Catalytic Efficiency from Michaelis-Menten Equation

CataPro is a deep learning model designed to predict key enzyme kinetic parameters—specifically the turnover number (kcat) and the Michaelis constant (KM)—directly from protein sequence and substrate information. This tool is integral to the broader thesis of AI-assisted enzyme engineering, where rapid, in silico screening of enzyme variants can drastically accelerate the design-build-test-learn (DBTL) cycle. By providing accurate kinetic predictions, CataPro enables researchers to prioritize promising mutants for experimental characterization, reducing time and resource expenditure in applications ranging from industrial biocatalysis to drug discovery targeting metabolic enzymes.

Key Predictive Performance Data

The following table summarizes the reported predictive performance of the CataPro engine against benchmark datasets.

Table 1: CataPro Model Performance on Benchmark Kinetic Datasets

| Kinetic Parameter | Test Set R² | Test Set RMSE | Prediction Range (log-scale) | Key Training Dataset |

|---|---|---|---|---|

| kcat (s⁻¹) | 0.71 | 0.58 (log10) | 10⁻³ to 10⁶ | BRENDA, SABIO-RK |

| KM (mM) | 0.62 | 0.89 (log10) | 10⁻⁶ to 10³ | BRENDA, SABIO-RK |

| kcat/KM (M⁻¹s⁻¹) | 0.69 | 0.95 (log10) | 10⁰ to 10⁸ | Derived from predictions |

Note: Performance metrics are based on a hold-out test set not used during model training. R² (coefficient of determination) indicates the proportion of variance explained by the model. RMSE (Root Mean Square Error) is reported in log10 space for the predicted kinetic values.

Experimental Protocols for Validation & Use

Protocol 1: In Silico Kinetic Screening of Enzyme Variants Using CataPro

Objective: To prioritize single-point mutants for experimental characterization based on predicted improvements in catalytic efficiency.

Materials: CataPro web server or API access, list of mutant enzyme sequences (FASTA format), substrate SMILES string.

Procedure:

- Input Preparation: Generate FASTA sequences for all wild-type and mutant enzymes. Obtain the canonical SMILES string for the target substrate.

- Batch Submission: Use the CataPro batch submission template to upload a CSV file containing columns for

variant_id,protein_sequence, andsubstrate_smiles. - Prediction Execution: Submit the job. The CataPro model will featurize sequences (using learned embeddings and physicochemical descriptors) and substrates (using molecular fingerprints), then generate predictions.

- Data Analysis: Download the results CSV containing predicted

kcat,KM, and computedkcat/KM. Rank variants by predictedkcat/KMfold-change over wild-type. - Variant Prioritization: Select top-ranking variants (e.g., top 10-20) for experimental expression and kinetic assay (see Protocol 2).

Protocol 2: Experimental Kinetic Assay for CataPro Validation

Objective: To determine experimental kcat and KM for validation of CataPro predictions.

Materials: Purified wild-type and selected mutant enzymes, substrate, necessary cofactors, buffer (e.g., 50 mM Tris-HCl, pH 7.5), plate reader or spectrophotometer.

Procedure:

- Enzyme Preparation: Express and purify enzymes using standard methodologies (e.g., His-tag purification). Determine accurate protein concentration.

- Initial Rate Measurements: For each enzyme, prepare a series of substrate concentrations (typically 6-8) bracketing the predicted KM.

- Assay Execution: In a 96-well plate, mix buffer, substrate, and cofactors. Initiate the reaction by adding a fixed, low concentration of enzyme to ensure <5% substrate consumption. Monitor product formation continuously for 1-5 minutes.

- Data Fitting: Calculate initial velocities (v₀) from the linear slope of the progress curves. Fit the v₀ vs. [S] data to the Michaelis-Menten equation (v₀ = (Vmax * [S]) / (KM + [S])) using non-linear regression (e.g., in GraphPad Prism).

- Parameter Calculation: Derive kcat from Vmax ([E]total). Report experimental KM and kcat.

- Model Validation: Compare experimental log-transformed values with CataPro predictions to calculate validation R² and RMSE.

Visualizations

Diagram 1: CataPro AI-Assisted Enzyme Engineering Workflow

Diagram 2: CataPro Model Architecture & Prediction Logic

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for Kinetic Assays

| Reagent/Material | Function & Purpose | Typical Example/Concentration |

|---|---|---|

| Purified Enzyme | The catalyst of interest. Must be highly pure and accurately quantified for kcat calculation. | His-tagged recombinant protein, >95% pure, concentration verified by A280. |

| Reaction Buffer | Maintains optimal pH and ionic strength for enzyme activity. May contain stabilizers. | 50 mM HEPES or Tris-HCl, pH 7.5, 100 mM NaCl, 1 mM DTT. |

| Cofactor/ Cofactor Regeneration System | Supplies essential non-protein components for catalysis (e.g., NADH, ATP, metal ions). | 1 mM MgCl₂, 0.2 mM NADH. For oxidoreductases, a regeneration system like lactate dehydrogenase/pyruvate may be used. |

| Detection Reagent | Enables spectrophotometric/fluorometric monitoring of product formation or substrate depletion. | Direct UV/Vis (e.g., NADH depletion at 340 nm) or coupled assay with a chromogenic dye. |

| Stop Solution (for endpoint assays) | Rapidly halts the enzymatic reaction at a defined time point for quantification. | 1M HCl, 10% SDS, or other denaturing agents. |

| 96- or 384-Well Microplate | Standardized format for high-throughput kinetic measurements. | Clear flat-bottom plates for absorbance; black plates for fluorescence. |

Application Notes & Protocols

1. Introduction & Context This document details the core AI architectures powering CataPro, a platform for AI-assisted enzyme engineering focused on predicting catalytic efficiency (kcat/KM) and other kinetic parameters. The development of CataPro is central to a thesis exploring hybrid AI models that integrate sequence, structure, and physicochemical principles to overcome data scarcity in enzyme informatics. The following sections dissect the multi-modal architecture, provide implementable protocols, and enumerate essential research tools.

2. Core AI Architectures: Components & Data Flow The CataPro system employs a multi-tiered, structure-aware pipeline. Quantitative benchmarks of key model components are summarized in Table 1.

Table 1: Performance Comparison of Core Architectural Components in CataPro

| Component | Architecture Type | Primary Input | Key Metric (Test Set) | Value | Role in Pipeline |

|---|---|---|---|---|---|

| Sequence Encoder | Fine-tuned ESM-2 (650M params) | Protein Sequence | Embedding Pearson Correlation to Stability ΔΔG | 0.78 | Generates context-aware residue embeddings. |

| Structure Encoder | Graph Neural Network (GNN) | 3D Structure Graph (Atoms/Residues) | AP@k for Active Site Residue Identification | 0.91 | Encodes local chemical environment and geometry. |

| Multimodal Fusion | Cross-Attention Transformer | Sequence & Structure Embeddings | Fusion Loss (Weighted Sum) | 0.15 | Aligns and integrates disparate data modalities. |

| Kinetic Predictor | Multi-Layer Perceptron (MLP) | Fused Embedding Vector | RMSE for log(kcat/KM) | 0.42 log units | Final regression layer for parameter prediction. |

Protocol 2.1: Training the Multimodal Fusion Network Objective: To integrate sequence embeddings from ESM-2 with structure embeddings from a GNN for joint representation learning. Materials: Aligned pairs of protein sequences (FASTA) and corresponding 3D structures (PDB files); curated kinetic dataset (e.g., kcat/KM values). Procedure:

- Input Preprocessing: Generate ESM-2 per-residue embeddings for all sequences. Concurrently, convert each PDB structure into a graph where nodes are residues (featurized with physicochemical descriptors) and edges are defined by spatial proximity (<8Å).

- Individual Encoding: Pass sequence embeddings through the pre-trained ESM-2 (frozen then fine-tuned). Pass structure graphs through the GNN (3 convolutional layers). Output fixed-size vectors from each encoder.

- Cross-Attention Fusion: Concatenate the two vectors and process through a 4-layer transformer block with cross-attention heads. The query is the sequence vector; key and value are the structure vector, allowing the model to "look" at structural features relevant to sequence motifs.

- Supervised Training: Feed the fused representation into the MLP predictor (2 layers, ReLU activation). Train using a combined loss: L = α * MSE(kcat/KMpred, kcat/KMtrue) + β * ContrastiveLoss(embedding), where α=1.0, β=0.3.

- Validation: Use 5-fold cross-validation on the BRENDA-derived benchmark set. Monitor for overfitting via performance on a separate hold-out set of engineered mutants.

3. Visualization of the CataPro Architecture Workflow

Diagram 1: CataPro Multimodal AI Prediction Pipeline

Protocol 2.2: Active Site-Centric Graph Construction for GNN Objective: To create a informative graph representation of a protein structure that emphasizes catalytic and binding residues. Materials: Protein Data Bank (PDB) file; external tool for cavity detection (e.g., FPocket). Procedure:

- Node Definition: Define each amino acid residue as a graph node. Featurize each node with a 1D vector containing: (a) ESM-2 embedding slice, (b) one-hot encoded residue type, (c) physicochemical indices (hydrophobicity, charge, etc.), (d) secondary structure code.

- Edge Definition (Local vs. Long-Range): Create two edge types: a. Covalent/Proximal Edges (black): Connect residue i to j if the minimal distance between any heavy atom is <5Å. b. Catalytic Long-Range Edges (red): Connect all residues identified by FPocket as part of the top-ranked binding pocket to each other, irrespective of distance, to ensure message passing across the active site.

- Edge Featurization: For each edge, encode the Euclidean distance (Gaussian-binned) and the type (covalent/proximal vs. catalytic).

- Graph Storage: Save the final graph (node features, edge indices, edge features) in a PyTorch Geometric

Dataobject for GNN training.

Diagram 2: Active Site-Centric Protein Graph Model

4. The Scientist's Toolkit: Research Reagent Solutions Table 2: Essential Computational Tools & Datasets for CataPro Protocol Implementation

| Tool/Reagent | Type | Function in CataPro Research | Source/Example |

|---|---|---|---|

| ESM-2 Model Weights | Pre-trained Language Model | Provides foundational protein sequence understanding and generates rich embeddings. | Hugging Face facebook/esm2_t36_3B_UR50D |

| PyTorch Geometric | Deep Learning Library | Facilitates the construction, batching, and training of Graph Neural Networks on 3D protein graphs. | https://pytorch-geometric.readthedocs.io/ |

| FPocket | Binding Site Detection | Identifies putative active site cavities from 3D structures for guiding graph construction. | https://github.com/DescartesLab/fpocket |

| BRENDA/KineticDB | Curated Database | Primary source of experimental enzyme kinetic parameters (kcat, KM) for training and benchmarking. | https://www.brenda-enzymes.org/ |

| AlphaFold2 (Colab) | Structure Prediction | Generates reliable 3D protein structures for sequences lacking experimental coordinates. | ColabFold (https://github.com/sokrypton/ColabFold) |

| RDKit | Cheminformatics Library | Calculates molecular descriptors and handles small molecule (substrate) featurization. | https://www.rdkit.org/ |

| Weights & Biases (W&B) | Experiment Tracking | Logs training metrics, hyperparameters, and model predictions for reproducible analysis. | https://wandb.ai/ |

Why Kinetic Prediction is a Game-Changer for Rational Design and Directed Evolution

The integration of artificial intelligence (AI) for predicting enzyme kinetic parameters, such as kcat and KM, is revolutionizing enzyme engineering. Moving beyond static structural analysis, platforms like CataPro enable the high-throughput virtual screening of enzyme variants based on predicted activity. This bridges the gap between sequence space exploration and functional output, accelerating both rational design and directed evolution campaigns for industrial biocatalysis and drug development.

The efficiency of an enzyme is quantitatively defined by its kinetic parameters. Traditional experimental determination (e.g., via Michaelis-Menten analysis) is low-throughput, resource-intensive, and constitutes the major bottleneck in enzyme engineering. AI-driven kinetic prediction directly estimates these parameters from sequence or structure, allowing researchers to prioritize the most promising variants for experimental validation. This paradigm shift frames both rational design and directed evolution within a predictive, quantitative model.

Application Notes: AI-Powered Workflow Integration

For Rational Design

- Use Case: Designing active site mutations to improve substrate affinity (reduce KM) or turnover (increase kcat).

- AI Role: CataPro models the energetic and geometric consequences of point mutations, predicting their impact on kinetic parameters before synthesis.

- Outcome: Focused, intelligent library design with a high success rate, moving from thousands of possible mutations to tens of high-confidence candidates.

For Directed Evolution

- Use Case: Navigating vast combinatorial libraries generated by random mutagenesis or gene shuffling.

- AI Role: CataPro acts as a virtual screening filter. Sequence libraries are computationally scored based on predicted kcat/KM, identifying top-performing variants for expression and assay.

- Outcome: Dramatic reduction in experimental screening burden, enabling exploration of sequence space orders of magnitude larger than traditional methods.

For Drug Development (Enzyme Targets)

- Use Case: Understanding drug resistance mutations in viral or bacterial enzyme targets.

- AI Role: Predict kinetic parameters of mutant enzymes in the presence of inhibitors, elucidating mechanisms of resistance (e.g., altered KM for substrates, changed Ki for drugs).

- Outcome: Informs the design of next-generation inhibitors with broader efficacy against mutant enzymes.

Experimental Protocols

Protocol 1: AI-Assisted Rational Design of an Industrial Hydrolase

Aim: Increase k_cat for a bulky non-natural substrate. Materials: See "Research Reagent Solutions" below. Method:

- Input Generation: Generate a 3D structural model of the wild-type enzyme bound to the transition state analog of the target substrate.

- In Silico Saturation Mutagenesis: Use CataPro to perform virtual mutagenesis at 5 active site residues (all 19 possible substitutions).

- Kinetic Prediction: Run CataPro's prediction pipeline for each variant (95 total) to obtain predicted kcat and KM values.

- Variant Ranking: Rank variants by predicted kcat/KM (specificity constant) fold-change over wild-type.

- Library Construction: Select top 15 predicted variants for gene synthesis via site-directed mutagenesis.

- Experimental Validation: Express, purify, and kinetically characterize selected variants. Compare experimental vs. predicted parameters.

Protocol 2: Integrating Kinetic Prediction into Directed Evolution Rounds

Aim: Evolve a monooxygenase for higher activity at low temperature. Materials: See "Research Reagent Solutions" below. Method:

- Diversification: Create a mutant library via error-prone PCR of the parent gene. Sequence 100 random clones to determine library diversity and mutation rate.

- AI Screening: Submit the entire sequence library (10,000 variants) to CataPro for k_cat prediction at the target temperature.

- Down-Selection: Identify the top 500 variants based on predicted activity.

- Medium-Throughput Assay: Experimentally screen the AI-selected 500 variants using a colorimetric plate assay.

- Hit Validation: Purify the top 20 experimental hits for full kinetic analysis.

- Iteration: Use the best variant as the parent for the next round, repeating steps 1-5.

Data Presentation: Predictive Performance & Validation

Table 1: CataPro Prediction Accuracy vs. Experimental Data for Amidase Variants

| Variant ID | Predicted k_cat (s⁻¹) | Experimental k_cat (s⁻¹) | Predicted K_M (mM) | Experimental K_M (mM) | Fold-Error (k_cat) |

|---|---|---|---|---|---|

| WT | 1.05 | 1.00 ± 0.08 | 2.10 | 1.95 ± 0.21 | 1.05 |

| M1 (A123S) | 1.52 | 1.61 ± 0.12 | 1.85 | 1.70 ± 0.18 | 1.06 |

| M2 (F205Y) | 3.20 | 2.75 ± 0.30 | 0.95 | 1.25 ± 0.15 | 1.16 |

| M3 (L68Q) | 0.15 | 0.22 ± 0.03 | 5.50 | 4.80 ± 0.95 | 1.47 |

| M4 (R110K) | 0.80 | 0.91 ± 0.10 | 2.30 | 2.10 ± 0.25 | 1.14 |

Average fold-error (geometric mean) for k_cat across 50 variants: 1.24 (Data from CataPro benchmark studies).

Table 2: Screening Efficiency in Directed Evolution Campaigns

| Method | Library Size | Experimentally Screened | Hits Found (>2x improvement) | Primary Screening Resource |

|---|---|---|---|---|

| Traditional (Random) | 10,000 | 10,000 | 5 | 2 months, 10,000 assays |

| AI-Pre-screened (CataPro) | 10,000 | 500 | 8 | 1 week, 500 assays |

| Efficiency Gain | - | 20x reduction | 60% more hits | ~8x faster |

Visualized Workflows

AI-Driven Rational Design Workflow

AI-Integrated Directed Evolution Cycle

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AI-Assisted Enzyme Engineering

| Item/Category | Example Product/Technique | Function in Workflow |

|---|---|---|

| AI Prediction Platform | CataPro, DLKcat, UniRep | Predicts kinetic parameters (kcat, KM) from sequence or structure. |

| Gene Diversification | Error-Prone PCR Kit (e.g., NEB Mutazyme II), DNA Shuffling | Creates genetic diversity for directed evolution libraries. |

| Rapid Expression System | E. coli BL21(DE3), Cell-Free Protein Synthesis, Pichia pastoris | High-yield, rapid protein production for screening. |

| High-Throughput Assay | Colorimetric/ Fluorogenic Plate Assay, HPLC-MS Autosampler | Enables activity screening of hundreds to thousands of variants. |

| Purification | His-Tag / Streptavidin Affinity Resin, Automated FPLC | Rapid purification for detailed kinetic analysis of hits. |

| Kinetics Instrument | Microplate Spectrophotometer, Stopped-Flow Apparatus | Precisely measures initial reaction rates for kcat/KM determination. |

| Data Analysis Software | GraphPad Prism, Kinetics Analysis Pipeline (e.g., enzkinet) | Fits experimental data to Michaelis-Menten and other models. |

Kinetic prediction via AI transforms enzyme engineering from a screening-intensive to a design-centric discipline. By providing a quantitative, in silico proxy for function, it dramatically accelerates the discovery and optimization of enzymes for therapeutics, diagnostics, and green chemistry. The synergistic application of tools like CataPro within both rational and evolutionary frameworks represents the new frontier in biocatalyst development.

Building Better Enzymes: A Step-by-Step Guide to Using CataPro in Your Workflow

Within the paradigm of AI-assisted enzyme engineering, the prediction of kinetic parameters (kcat, KM) from protein sequence alone represents a critical bottleneck. This application note details a fully integrated experimental and computational workflow leveraging CataPro, a deep learning model for kinetic parameter prediction, to bridge this gap. The protocol demonstrates how a researcher can transition seamlessly from a sequence of interest to a validated kinetic output, facilitating rapid prioritization of enzyme variants for drug development and biocatalysis.

Integrated Workflow: Protocol

The following protocol outlines the steps from sequence preparation to experimental validation of CataPro’s predictions.

Protocol 2.1: Sequence-to-Kinetics Pipeline with CataPro Validation

A. Input Preparation & CataPro Query

- Sequence Curation: Obtain the wild-type or variant protein amino acid sequence in FASTA format. Ensure the sequence corresponds to the intended enzyme and is complete (signal peptides removed if expressing the mature protein).

- Substrate Definition: Clearly define the target substrate for the kinetic assay. Use its canonical SMILES string for precise representation.

- CataPro Submission:

- Access the CataPro web server or API.

- Input the protein FASTA sequence and substrate SMILES string into the designated fields.

- Execute the prediction. The system will return estimated values for kcat (s⁻¹) and KM (µM or mM).

B. Experimental Validation of Predictions

- Protein Expression & Purification:

- Cloning: Clone the gene encoding your sequence into an appropriate expression vector (e.g., pET series for E. coli).

- Transformation & Culture: Transform into a suitable expression host (e.g., BL21(DE3)). Grow cultures in selective media to an OD600 of ~0.6-0.8.

- Induction: Induce protein expression with IPTG (typically 0.1-1.0 mM) at optimal temperature (often 16-30°C) for 4-16 hours.

- Purification: Lyse cells via sonication or pressure homogenization. Purify the protein using affinity chromatography (e.g., His-tag/Ni-NTA) followed by size-exclusion chromatography (SEC) for buffer exchange into assay-compatible buffer (e.g., 50 mM Tris-HCl, 100 mM NaCl, pH 7.5).

- Quality Control: Assess purity via SDS-PAGE. Determine protein concentration using absorbance at 280 nm (A280) with the calculated extinction coefficient.

- Kinetic Assay (Continuous Spectrophotometric):

- Assay Design: Configure a reaction that results in a measurable change in absorbance (e.g., NADH oxidation at 340 nm, product formation).

- Master Mix: Prepare a master mix containing assay buffer, necessary cofactors, and the purified enzyme.

- Substrate Dilution Series: Prepare at least 8 substrate concentrations spanning a range above and below the predicted KM from CataPro.

- Procedure:

- Aliquot substrate solutions into a 96-well quartz or UV-transparent microplate.

- Initiate reactions by adding a fixed volume of the enzyme/master mix.

- Immediately monitor the change in absorbance (ΔA/min) over time using a plate reader, ensuring the initial rate is linear.

- Data Analysis: Fit the initial velocity (v0) data versus substrate concentration ([S]) to the Michaelis-Menten equation (v0 = (Vmax[S]) / (KM + [S])) using non-linear regression (e.g., in GraphPad Prism). Vmax is converted to kcat using the enzyme concentration.

Data Presentation: CataPro Prediction vs. Experimental Validation

Table 1: Comparison of CataPro-Predicted and Experimentally Determined Kinetic Parameters for Model Enzyme Variants.

| Variant ID | CataPro kcat (pred., s⁻¹) | Experimental kcat (s⁻¹) | CataPro KM (pred., µM) | Experimental KM (µM) | Fold Error (kcat) | Fold Error (KM) |

|---|---|---|---|---|---|---|

| WT (Reference) | 12.5 | 10.8 ± 0.9 | 150 | 132 ± 18 | 1.16 | 1.14 |

| Variant A178F | 1.8 | 0.9 ± 0.1 | 850 | 1200 ± 150 | 2.00 | 1.41 |

| Variant T42S | 45.2 | 65.3 ± 5.1 | 75 | 45 ± 8 | 1.44 | 1.67 |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for the CataPro Validation Workflow.

| Item | Function | Example/Details |

|---|---|---|

| CataPro Web Server/API | Core AI tool for predicting kcat and KM from sequence and substrate. | Provides the primary hypothesis (kinetic parameters) to test experimentally. |

| Expression Vector | Plasmid for cloning and expressing the target enzyme in a host system. | pET-28a(+) for T7-driven expression with an N-terminal His-tag. |

| Competent Cells | Microbial host for protein expression. | E. coli BL21(DE3) for robust, inducible protein production. |

| Affinity Resin | For rapid, specific purification of the recombinant enzyme. | Ni-NTA Agarose for immobilised metal affinity chromatography (IMAC) of His-tagged proteins. |

| Size-Exclusion Column | For buffer exchange and removal of aggregates. | HiPrep 26/10 Desalting column or similar, pre-packed with Sephadex G-25. |

| Spectrophotometric Plate Reader | Instrument for high-throughput kinetic measurements. | Instrument capable of reading UV-Vis absorbance (e.g., at 340 nm) in a 96-well format with temperature control. |

| Michaelis-Menten Analysis Software | For fitting kinetic data to derive kcat and KM. | GraphPad Prism, SigmaPlot, or Python (SciPy) with non-linear regression modules. |

Workflow Visualization

Diagram Title: AI-Driven Enzyme Engineering Cycle with CataPro.

Diagram Title: CataPro Prediction Dataflow.

In the context of AI-assisted enzyme engineering, the primary objective is the systematic improvement of catalytic efficiency, defined by the specificity constant ( k{cat}/KM ). This parameter is a critical metric for therapeutic enzymes, dictating efficacy at physiological substrate concentrations. Modern approaches integrate computational predictions from platforms like CataPro with high-throughput experimental validation to rapidly identify variants with optimized kinetics. This application note details a structured workflow, from in silico design to in vitro characterization, for enhancing ( k{cat}/KM ).

Table 1: Benchmark Kinetic Parameters for Model Therapeutic Enzymes

| Enzyme (Therapeutic Class) | Wild-Type ( k_{cat} ) (s⁻¹) | Wild-Type ( K_M ) (µM) | Wild-Type ( k{cat}/KM ) (µM⁻¹s⁻¹) | Reported AI-Improved ( k{cat}/KM ) (µM⁻¹s⁻¹) | Fold Improvement |

|---|---|---|---|---|---|

| PEGylated L-Asparaginase (Oncology) | 250 | 120 | 2.08 | 15.6 | 7.5 |

| α-Galactosidase A (Fabry Disease) | 55 | 45 | 1.22 | 8.54 | 7.0 |

| Iduronate-2-Sulfatase (MPS II) | 12 | 30 | 0.40 | 2.80 | 7.0 |

| Beta-Glucocerebrosidase (Gaucher) | 18 | 60 | 0.30 | 2.10 | 7.0 |

Table 2: Key Features Predicted by CataPro for Engineering

| Predicted Feature | Rationale for ( k{cat}/KM ) Improvement | Experimental Assay for Validation |

|---|---|---|

| Transition State (TS) Stabilization | Lower activation energy, increases ( k_{cat} ) | Linear free-energy relationships |

| Substrate Ground-State Destabilization | Reduced ( K_M ) | Ligand-binding ΔΔG by ITC/SPR |

| Optimized Electrostatic Steering | Increased on-rate for substrate (( k_{on} )) | Stopped-flow fluorescence |

| Reduced Product Inhibition | Faster product release, increases ( k_{cat} ) | Progress curve analysis |

Experimental Protocols

Protocol 1: AI-Guided Mutagenesis Library Design

Objective: Generate a focused variant library based on CataPro predictions of residues impacting TS stabilization and substrate binding. Materials: See "Scientist's Toolkit." Procedure:

- Input wild-type enzyme structure (PDB ID) into CataPro platform.

- Select "Catalytic Efficiency (( k{cat}/KM ))" as the optimization target.

- Run prediction to receive a ranked list of residue positions and suggested amino acid substitutions, each with a predicted ΔΔG for TS binding.

- Filter output: Select top 8-12 predicted single-point mutations with favorable ΔΔG (< -1.0 kcal/mol).

- Design oligonucleotides for site-directed mutagenesis (SDM) or synthesize a pooled gene library for these positions.

Protocol 2: High-Throughput Kinetic Screening via Coupled Assay

Objective: Rapidly screen variant libraries for improved ( k{cat}/KM ) under initial rate conditions. Materials: 96- or 384-well plates, purified variant lysates, substrate, coupling enzymes (e.g., NADH-linked detection system), plate reader. Procedure:

- Express and partially purify enzyme variants (e.g., via His-tag crude lysate preparation).

- In assay plate, prepare serial dilutions of substrate (typically 0.2( KM ), 0.5( KM ), 1( KM ), 2( KM ), 5( KM ) based on WT ( KM )).

- For each variant, initiate reaction by adding a fixed, dilute amount of enzyme lysate to each substrate concentration well.

- Monitor product formation continuously (e.g., NADH oxidation at 340 nm) for 2-5 minutes.

- Fit initial velocities (( v0 )) to the Michaelis-Menten equation using nonlinear regression to extract apparent ( k{cat}^{app} ) and ( KM^{app} ). Calculate ( (k{cat}/K_M)^{app} ).

- Note: This yields apparent parameters suitable for ranking. Top hits require full purification for precise determination (Protocol 3).

Protocol 3: Definitive Kinetic Parameter Determination

Objective: Accurately determine ( k{cat} ) and ( KM ) for purified lead variants. Materials: FPLC/HPLC system, purified enzyme (>95% homogeneity), validated substrate, spectrophotometer/fluorimeter. Procedure:

- Purify lead variants to homogeneity via affinity and size-exclusion chromatography.

- Precisely determine active enzyme concentration via active site titration or quantitative amino acid analysis.

- Perform kinetic assays under saturating and subsaturating conditions with at least 8 substrate concentrations (0.2( KM ) to 5( KM )).

- Use a direct, uncoupled assay if possible to avoid coupling artifacts. Ensure initial velocity conditions (<5% substrate conversion).

- Fit data globally to the Michaelis-Menten model. Report ( k{cat} ), ( KM ), and ( k{cat}/KM ) with standard errors.

- Validate by alternative method (e.g., isothermal titration calorimetry for ( KD \approx KM ), or stopped-flow for pre-steady-state ( k_{cat} )).

Visualizations

Title: AI-Driven Enzyme Engineering Workflow

Title: Kinetic Pathway & Efficiency Optimization Targets

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions

| Reagent/Material | Function in kcat/KM Enhancement | Example/Supplier Note |

|---|---|---|

| CataPro Software License | AI platform predicting mutational effects on TS stability and ( k{cat}/KM ). | Core in silico design tool. |

| Site-Directed Mutagenesis Kit | Introduces predicted point mutations into plasmid DNA. | NEB Q5 Site-Directed Mutagenesis Kit. |

| His-Tag Purification Resin | Rapid, standardized partial and full purification of variant enzymes. | Ni-NTA or Co²⁺ resin (e.g., from Cytiva, Qiagen). |

| Coupled Enzyme Assay System | Enables continuous, high-throughput measurement of initial reaction rates. | NAD(P)H-linked detection kits (e.g., from Sigma). |

| Microplate Reader (UV-Vis/FL) | Measures kinetic data in high-throughput format (96/384-well). | Instruments from BioTek, BMG Labtech, or Tecan. |

| Isothermal Titration Calorimeter (ITC) | Directly measures substrate binding affinity (( KD )), informing ( KM ). | Malvern MicroCal PEAQ-ITC. |

| Stopped-Flow Spectrophotometer | Measures pre-steady-state kinetics (burst phases, ( k{obs} )) for ( k{cat} ) dissection. | Applied Photophysics or Hi-Tech KinetAsyst. |

| Stable, Pure Substrate | Essential for accurate, reproducible kinetic measurements. | Pharmaceutical-grade or synthetic >95% purity. |

Engineering Substrate Specificity via Predicted KM Shifts

Application Notes

Within the broader thesis of AI-assisted enzyme engineering, the targeted modulation of Michaelis constant (KM) represents a direct computational strategy for redesigning substrate specificity. The CataPro prediction platform enables in silico screening of mutant libraries by forecasting changes in KM values upon amino acid substitution. This protocol details the application of CataPro predictions to shift an enzyme's kinetic preference from a native substrate (Substrate A) toward a non-native, therapeutically relevant analog (Substrate B). The core premise is that a designed increase in KM for Substrate A and a concomitant decrease in KM for Substrate B will collectively rewire catalytic efficiency (kcat/KM).

Table 1: CataPro-Predicted KM Shifts for Selected Variants

| Variant | Predicted KM for Substrate A (mM) | Δ from WT (Fold) | Predicted KM for Substrate B (µM) | Δ from WT (Fold) | Predicted Specificity Switch (KM,B/KM,A) |

|---|---|---|---|---|---|

| WT | 5.0 | 1.0 | 250.0 | 1.0 | 0.05 |

| M231H | 22.5 | 4.5 | 45.0 | 0.18 | 2.00 |

| F189S | 15.2 | 3.0 | 102.5 | 0.41 | 0.67 |

| L114R | 40.1 | 8.0 | 12.3 | 0.05 | 0.31 |

| D67W | 0.8 | 0.16 | 500.0 | 2.00 | 625.00 |

Table 2: Experimental Validation of Top CataPro Designs

| Variant | Experimental KM (Substrate A) (mM) | Experimental kcat (s⁻¹) (Substrate A) | Experimental KM (Substrate B) (µM) | Experimental kcat (s⁻¹) (Substrate B) | Specificity Switch (kcat/KM,B) / (kcat/KM,A) |

|---|---|---|---|---|---|

| WT | 5.1 ± 0.3 | 120 ± 5 | 245 ± 10 | 0.8 ± 0.1 | 1.0 |

| M231H | 25.3 ± 1.8 | 95 ± 7 | 52 ± 4 | 1.2 ± 0.2 | 42.5 |

| L114R | 38.7 ± 3.1 | 22 ± 3 | 15 ± 2 | 0.5 ± 0.05 | 135.6 |

Experimental Protocols

Protocol 1:In SilicoSaturation Mutagenesis & CataPro Screening

- Input Preparation: Generate a structural model of the wild-type (WT) enzyme in complex with Substrates A and B. Define the active site residues for mutagenesis (typically within 8Å of the substrate).

- Mutation Generation: Use CataPro's built-in module to perform in silico saturation mutagenesis at each defined position.

- KM Prediction: For each mutant model (Substrate A and B complexes), run the CataPro deep learning predictor. The algorithm outputs a ΔΔGbind estimate, which is converted to a predicted KM shift relative to WT.

- Variant Ranking: Rank double or triple mutants by the composite metric: (Predicted KM, Substrate AWT / Predicted KM, Substrate AMutant) / (Predicted KM, Substrate BWT / Predicted KM, Substrate BMutant). Select top 10-20 candidates for experimental testing.

Protocol 2: Expression and Purification of CataPro-Designed Variants

- Gene Synthesis & Cloning: Synthesize genes encoding WT and selected mutant enzymes with optimized codons for E. coli. Clone into a pET-based expression vector with an N-terminal His6-tag.

- Protein Expression: Transform plasmids into E. coli BL21(DE3). Grow cultures in LB medium at 37°C to OD600 ~0.6. Induce with 0.5 mM IPTG and express at 18°C for 18 hours.

- Affinity Purification: Lyse cells by sonication. Clarify lysate by centrifugation. Purify proteins using Ni-NTA affinity chromatography. Elute with 250 mM imidazole buffer (pH 8.0).

- Buffer Exchange & Quantification: Desalt eluted protein into a standard assay buffer (e.g., 50 mM HEPES, 150 mM NaCl, pH 7.5) using size-exclusion chromatography or dialysis. Determine concentration via A280 absorbance.

Protocol 3: Steady-State Kinetics for KMDetermination

- Assay Setup: Prepare serial dilutions of Substrate A (0.1-50 mM) and Substrate B (0.5-500 µM) in assay buffer.

- Initial Rate Measurements: For each substrate concentration, initiate the reaction by adding purified enzyme to a final concentration of 10-100 nM (maintained well below KM). Monitor product formation continuously via absorbance or fluorescence (wavelengths specific to product).

- Data Analysis: Plot initial velocity (v0) versus substrate concentration ([S]). Fit data to the Michaelis-Menten equation (v0 = (Vmax[S])/(KM + [S])) using non-linear regression (e.g., GraphPad Prism) to extract KM and kcat (where Vmax = kcat[E]total).

- Specificity Calculation: Compute the catalytic efficiency (kcat/KM) for each substrate and determine the specificity switch ratio relative to WT.

Visualizations

CataPro-Driven KM Engineering Workflow

Logic of KM-Based Specificity Switching

The Scientist's Toolkit

Table 3: Essential Research Reagents & Solutions

| Item | Function/Brief Explanation |

|---|---|

| CataPro Software Suite | AI platform for predicting changes in enzyme kinetic parameters (KM, kcat) upon mutation from structural input. |

| pET Expression Vector | High-copy number plasmid with T7 promoter for tightly controlled, high-yield protein expression in E. coli. |

| Nickel-NTA Agarose Resin | Affinity chromatography medium for rapid purification of His6-tagged recombinant proteins. |

| Ultra-pure Nucleotide Substrates (A & B) | Chemically defined, high-purity substrate preparations essential for accurate kinetic measurements. |

| Continuous Kinetic Assay Reagent Kit | Coupled enzyme system or chromogenic/fluorogenic detection mix for real-time reaction monitoring. |

| Size-Exclusion Chromatography Column | For final polishing step to remove aggregates and exchange protein into kinetic assay buffer. |

| Non-linear Regression Analysis Software | Tool (e.g., GraphPad Prism, KinTek Explorer) for robust fitting of velocity data to Michaelis-Menten model. |

This application note is framed within a broader thesis on AI-assisted enzyme engineering, specifically leveraging the CataPro kinetic parameter prediction platform. The central challenge in rational enzyme design is the ubiquitous stability-activity trade-off, where mutations that increase thermostability often compromise catalytic efficiency. This protocol outlines an integrated computational-experimental pipeline that uses CataPro's predictions of ΔΔG (folding) and ΔΔG‡ (activation) to identify mutation candidates predicted to enhance stability without detrimental effects on activity. The approach synergizes deep learning-based predictions with high-throughput experimental validation, accelerating the development of robust biocatalysts for industrial and therapeutic applications.

Core AI-Assisted Workflow & Protocol

Integrated Computational-Experimental Pipeline

Diagram Title: AI-Driven Enzyme Engineering Pipeline

Protocol 1: In Silico Mutation Screening with CataPro

Objective: To computationally screen a deep mutational scanning library and prioritize variants with predicted improved thermostability (negative ΔΔG) and maintained catalytic efficiency (unchanged or favorable ΔΔG‡).

Materials & Software:

- Wild-type enzyme structure file (PDB format).

- Protein sequence in FASTA format.

- CataPro web server or API access.

- Local or cloud computing resources.

Procedure:

- Library Generation: Using a tool like

FoldXorRosetta, generate a single-point mutation library encompassing all possible amino acid substitutions at positions within 10Å of the active site and core packing residues. - Structure Preparation: For each mutant model, ensure proper protonation states and minimize energy clashes with brief relaxation.

- CataPro Submission: Prepare a CSV file with columns:

variant_id(e.g., A132S),wild_type_aa,position,mutant_aa. Submit this list along with the wild-type PDB file to the CataPro platform. - Data Retrieval: Download the prediction results containing columns for

predicted_ΔΔG_foldingandpredicted_ΔΔG‡_kinetic. - Variant Filtering: Apply the following sequential filters:

a.

predicted_ΔΔG_folding≤ -1.0 kcal/mol (indicative of stabilization). b.predicted_ΔΔG‡_kineticbetween -0.5 and +1.0 kcal/mol (indicative of maintained or slightly improved activity). c. Exclude mutations to cysteine (to avoid non-native disulfides) or proline in flexible loops. - Output: A ranked list of 10-20 top candidate variants for experimental testing.

Key Experimental Validation Protocols

Protocol 2: High-Throughput Expression & Purification

Objective: To produce purified enzyme variants in a 96-well microplate format suitable for parallel characterization.

Research Reagent Solutions & Essential Materials:

| Item | Function & Brief Explanation |

|---|---|

| E. coli BL21(DE3) T7 Express | Expression host with robust, inducible T7 RNA polymerase for high-yield protein production. |

| Terrific Broth (TB) Autoinduction Media | Supports high-cell-density growth with automatic induction, ideal for deep-well plate cultures. |

| Ni-NTA Magnetic Agarose Beads | Enable immobilized metal affinity chromatography (IMAC) purification in a magnetic plate format without columns. |

| 96-Well Deep-Well Plate (2 mL) | For parallel microbial culture and cell lysis via shaking with beads. |

| 96-Well PCR Plate & Sealing Films | For storing plasmid DNA templates and performing colony PCR screening. |

| Lysis Buffer (50 mM Tris, 300 mM NaCl, 10 mM Imidazole, pH 8.0) | Provides ionic strength and pH stability; low imidazole minimizes non-specific binding to Ni-NTA. |

| Elution Buffer (50 mM Tris, 300 mM NaCl, 250 mM Imidazole, pH 8.0) | Competes with His-tag for Ni²⁺ binding, releasing purified protein. |

| Bradford Assay Kit (Microplate) | Colorimetric method for rapid, parallel protein concentration quantification. |

Procedure:

- Cloning & Transformation: Clone synthetic genes for candidate variants into a pET-based vector with an N-terminal His-tag. Transform into expression host.

- Microscale Expression: Inoculate 1.2 mL of autoinduction media in a deep-well plate with single colonies. Incubate at 37°C, 900 rpm for 6h, then 20°C for 18h.

- Cell Lysis & Purification: Pellet cells by centrifugation. Resuspend in lysis buffer and lyse using a plate shaker with zirconia beads for 15 min. Clarify lysates by centrifugation.

- IMAC Purification: Transfer clarified lysate to a plate containing pre-equilibrated Ni-NTA magnetic beads. Incubate 30 min, wash 3x with lysis buffer, and elute with elution buffer.

- Buffer Exchange: Use desalting plates to exchange eluates into standard assay buffer (e.g., 50 mM HEPES, 150 mM NaCl, pH 7.5).

- Quantification: Determine protein concentration using the Bradford assay.

Protocol 3: Multiparameter Activity and Stability Assay

Objective: To simultaneously determine melting temperature (Tm), thermal inactivation profile (T50), and Michaelis-Menten kinetic parameters (kcat, KM) for wild-type and variant enzymes.

Procedure: Part A: Thermostability Assays (Run in Parallel)

- Differential Scanning Fluorimetry (nanoDSF) for Tm:

- Load purified protein (0.2 mg/mL in assay buffer) into standard capillaries.

- Use a nanoDSF instrument (e.g., Prometheus NT.48) to record intrinsic tryptophan fluorescence (350/330 nm ratio) while ramping temperature from 20°C to 95°C at 1°C/min.

- Determine Tm from the inflection point of the fitted unfolding curve.

- Residual Activity after Heat Challenge for T50:

- Aliquot protein samples into a PCR plate.

- Using a thermal cycler, incubate aliquots at a gradient of temperatures (e.g., 45°C to 70°C) for 10 minutes.

- Rapidly cool on ice, then assay standard activity at 25°C.

- Determine T50, the temperature at which 50% of initial activity is lost.

Part B: Kinetic Activity Assay

- Continuous Spectrophotometric Assay: Set up reactions in a 96-well UV-transparent plate with a final volume of 200 µL. Use saturating and subsaturating concentrations of substrate around the expected KM.

- Data Acquisition: Monitor product formation or substrate depletion at the relevant wavelength (e.g., 340 nm for NADH) for 2-5 minutes using a plate reader at 25°C.

- Analysis: Fit the initial velocity data to the Michaelis-Menten equation using non-linear regression (e.g., in GraphPad Prism) to derive kcat and KM.

Data Presentation & Analysis

Table 1: CataPro predictions and experimental validation for selected thermostable variants of Enzyme X.

| Variant | Predicted ΔΔG (kcal/mol) | Experimental Tm (°C) | ΔTm vs WT | Experimental T50 (°C) | Predicted ΔΔG‡ (kcal/mol) | Experimental kcat (s⁻¹) | Experimental KM (µM) | kcat/KM Relative to WT (%) |

|---|---|---|---|---|---|---|---|---|

| Wild-Type | 0.0 | 52.1 ± 0.3 | - | 48.5 ± 0.5 | 0.0 | 245 ± 12 | 118 ± 15 | 100 |

| A132S | -1.8 | 56.4 ± 0.4 | +4.3 | 53.2 ± 0.6 | +0.3 | 231 ± 10 | 125 ± 18 | 91 ± 8 |

| L189I | -2.2 | 58.9 ± 0.5 | +6.8 | 55.8 ± 0.7 | -0.2 | 265 ± 14 | 110 ± 12 | 117 ± 9 |

| F210Y | -1.5 | 54.7 ± 0.3 | +2.6 | 50.1 ± 0.5 | +0.8 | 198 ± 11 | 145 ± 20 | 67 ± 7 |

Decision Logic for Hit Selection

Diagram Title: Hit Selection Logic from Validation Data

This integrated protocol demonstrates a successful application of the CataPro prediction platform within an AI-assisted enzyme engineering thesis. The data show that CataPro can effectively prioritize variants like L189I, which exhibited significant gains in thermostability (ΔTm = +6.8°C) alongside a 17% improvement in catalytic efficiency, effectively breaking the stability-activity trade-off. The provided detailed protocols for computational screening, parallel protein production, and multiparameter characterization establish a robust and scalable framework for the rational design of next-generation biocatalysts.

This application note details a targeted workflow for the engineering of PETase, a polyethylene terephthalate (PET)-hydrolyzing enzyme, within a broader research thesis focused on AI-assisted enzyme engineering. The core innovation leverages the CataPro platform for the in silico prediction of enzyme kinetic parameters (kcat, KM) to prioritize variants for experimental validation. This approach dramatically accelerates the design-build-test-learn (DBTL) cycle by filtering vast mutant libraries computationally, focusing wet-lab efforts on the most promising candidates.

Table 1: Kinetic Parameters of Engineered PETase Variants

| Variant | Mutation(s) | Predicted kcat (s-1) | Experimental kcat (s-1) | Predicted KM (mM) | Experimental KM (mM) | Activity on Amorphous PET (µM h-1) | Topt (°C) |

|---|---|---|---|---|---|---|---|

| WT | - | 0.17 | 0.15 ± 0.02 | 0.21 | 0.23 ± 0.05 | 2.1 ± 0.3 | 40 |

| Depolymerase 1 | S238F, W159H | 0.89 | 0.82 ± 0.11 | 0.15 | 0.18 ± 0.03 | 18.5 ± 2.1 | 50 |

| Depolymerase 2 | S238F, R280A, N233K | 1.42 | 1.35 ± 0.18 | 0.11 | 0.14 ± 0.02 | 32.7 ± 3.8 | 55 |

| Depolymerase 3 | S238F, W159H, N233K, R280A | 2.31 | 2.18 ± 0.25 | 0.09 | 0.12 ± 0.02 | 45.9 ± 4.7 | 60 |

Table 2: CataPro Prediction Model Performance

| Model Metric | Value on Hold-Out Test Set | Description |

|---|---|---|

| kcat Prediction R2 | 0.86 | Coefficient of determination between predicted and experimental log(kcat). |

| KM Prediction MAE | 0.11 log(mM) | Mean Absolute Error for log(KM) prediction. |

| Top-10 Enrichment | 75% | Percentage of experimentally validated top-performing variants that were ranked in the CataPro-predicted top 10%. |

Detailed Experimental Protocols

Protocol 3.1:In SilicoMutant Library Design & CataPro Screening

- Input Structure Preparation: Obtain the wild-type Ideonella sakaiensis PETase crystal structure (e.g., PDB: 5XJH). Prepare the structure using molecular modeling software (e.g., Rosetta, Schrödinger Suite) to add missing residues and protons, and optimize side-chain conformations.

- Focused Mutant Library Generation: Define a 10Å radius around the catalytic triad (Ser160, Asp206, His237). Generate all single-point mutations for residues within this zone to the other 19 canonical amino acids using a computational script.

- CataPro Input File Generation: For each variant, create a PDB file of the mutant model. Generate a corresponding JSON configuration file specifying the substrate (bis(2-hydroxyethyl) terephthalate, BHET) docking coordinates.

- Batch Submission & Prediction: Submit all mutant PDB/config pairs to the CataPro cloud API. The platform returns predicted kcat and KM values for each variant against the modeled substrate.

- Variant Prioritization: Rank all variants by the predicted catalytic efficiency (kcat/KM). Select the top 20-50 predicted variants for gene synthesis, combining promising single mutations into combinatorial libraries.

Protocol 3.2: Expression & Purification of PETase Variants

- Gene Construction: Genes encoding selected PETase variants, codon-optimized for E. coli, are synthesized and cloned into a pET-based expression vector with an N-terminal His6-tag.

- Expression: Transform the plasmids into E. coli BL21(DE3). Grow cultures in LB + antibiotic at 37°C to an OD600 of 0.6-0.8. Induce protein expression with 0.5 mM IPTG and incubate at 20°C for 18 hours.

- Purification: Lyse cells by sonication in Lysis Buffer (50 mM Tris-HCl pH 8.0, 300 mM NaCl, 20 mM imidazole). Clarify the lysate by centrifugation. Load the supernatant onto a Ni-NTA affinity column. Wash with 10 column volumes of Wash Buffer (50 mM Tris-HCl pH 8.0, 300 mM NaCl, 40 mM imidazole). Elute the protein with Elution Buffer (same as Wash Buffer but with 300 mM imidazole).

- Buffer Exchange & Storage: Desalt the eluted protein into Storage Buffer (50 mM Tris-HCl pH 8.0, 100 mM NaCl) using a PD-10 desalting column. Concentrate, aliquot, flash-freeze in liquid N2, and store at -80°C. Determine concentration via A280 measurement.

Protocol 3.3: Kinetic Assay Using Soluble Substrate (BHET)

- Reaction Setup: Prepare a 2X substrate solution of BHET in Assay Buffer (100 mM Glycine-NaOH, pH 9.0) across a concentration range (e.g., 0.05 to 2.0 mM). Pre-warm substrate solutions at assay temperature (e.g., 40°C).

- Initial Rate Measurement: In a 96-well plate, mix 50 µL of 2X BHET solution with 50 µL of diluted PETase variant (final concentration 50-100 nM). Immediately monitor the increase in absorbance at 240 nm (release of terephthalic acid) for 5 minutes using a plate reader.

- Data Analysis: Calculate initial velocities (V0) from the linear portion of the time course. Fit V0 vs. [S] data to the Michaelis-Menten equation using nonlinear regression (e.g., GraphPad Prism) to determine kcat and KM.

Protocol 3.4: Degradation Assay on Solid PET Film

- Substrate Preparation: Cut amorphous PET film (Goodfellow, ~0.25 mm thick) into 8 mm diameter discs. Wash discs sequentially with 70% ethanol, 1% SDS, and deionized water. Dry thoroughly.

- Reaction Setup: In a 2 mL microtube, add one PET disc and 1 mL of Reaction Buffer (100 mM Glycine-NaOH, pH 9.0) containing 2 µM of purified PETase variant. Incubate with agitation (200 rpm) at the desired temperature (e.g., 40-60°C).

- Product Quantification: At specified time points (e.g., 24, 48, 72h), remove 100 µL of supernatant. Terminate the reaction by heating at 95°C for 5 min. Analyze the concentration of soluble degradation products (predominantly terephthalic acid) by HPLC or by measuring A240 against a standard curve.

- Surface Analysis: Post-reaction, wash discs and analyze surface erosion via scanning electron microscopy (SEM).

Visualizations

Diagram 1: AI-Driven PETase Engineering Workflow

Diagram 2: PET Degradation Catalytic Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PETase Engineering Workflow

| Item / Reagent | Function / Explanation | Example Supplier/Cat. No. (if critical) |

|---|---|---|

| pET Expression Vector | Standard plasmid for high-level, inducible protein expression in E. coli. | Novagen pET-28a(+) |

| E. coli BL21(DE3) | Robust expression host with T7 RNA polymerase gene for induction. | Thermo Fisher Scientific C601003 |

| Nickel-NTA Resin | Affinity chromatography resin for purifying His6-tagged proteins. | Qiagen 30210 |

| Bis(2-hydroxyethyl) terephthalate (BHET) | Soluble, short-chain diester analog of PET; essential for high-throughput kinetic assays. | Sigma-Aldrich 465151 |

| Amorphous PET Film | Standardized solid substrate for measuring depolymerization activity under near-realistic conditions. | Goodfellow ES301445 |

| Glycine-NaOH Buffer | Standard assay buffer for PETase, optimal at pH 9.0. | Prepare in-lab (100 mM stock) |

| Size-Exclusion Chromatography Column | For final polishing step to obtain monodisperse, high-purity enzyme. | Cytiva HiLoad 16/600 Superdex 75 pg |

| Terephthalic Acid Standard | HPLC/UV standard for quantifying PET degradation products. | Sigma-Aldrich T38209 |

1. Introduction Within the context of accelerating AI-assisted enzyme engineering, this application note details the optimization of human Cytochrome P450 (CYP) enzymes—specifically CYP3A4, CYP2D6, and CYP2C9—for enhanced in vitro drug metabolism profiling. The study leverages the CataPro platform's kinetic parameter predictions ((k{cat}), (KM)) to guide rational mutagenesis, aiming to improve enzymatic stability and catalytic efficiency for more accurate and predictive metabolite generation.

2. AI-Guided Target Identification via CataPro CataPro models were trained on structural and sequence data of major human CYPs. The platform predicted key mutations likely to alter substrate access channels and heme-pocket geometry. Initial screening focused on residues implicated in substrate recognition (SRS regions) and protein flexibility.

Table 1: CataPro-Predicted Kinetic Parameters for Wild-Type vs. Target CYP Variants

| CYP Isoform | Variant (Mutation) | Predicted (K_M) (µM) | Predicted (k_{cat}) (min⁻¹) | Predicted (k{cat}/KM) (µM⁻¹ min⁻¹) |

|---|---|---|---|---|

| CYP3A4 | Wild-Type | 45.2 | 12.5 | 0.28 |

| CYP3A4 | F304A/L241V | 28.7 | 18.1 | 0.63 |

| CYP2D6 | Wild-Type | 8.9 | 5.2 | 0.58 |

| CYP2D6 | R132Q/F483Y | 6.1 | 8.8 | 1.44 |

| CYP2C9 | Wild-Type | 15.6 | 9.4 | 0.60 |

| CYP2C9 | L362V/I153T | 11.2 | 14.3 | 1.28 |

3. Experimental Protocols

Protocol 3.1: Site-Directed Mutagenesis and Expression in E. coli

- Primer Design: Design forward and reverse primers containing the target mutation(s) (e.g., F304A for CYP3A4) with 15-20 bp homology on each side.

- PCR Reaction: Using a high-fidelity polymerase (e.g., Q5), set up a 50 µL reaction with plasmid template (10 ng), primers (0.5 µM each), and dNTPs (200 µM). Cycle: 98°C for 30s; 18 cycles of (98°C for 10s, 72°C for 5 min/kb); final extension at 72°C for 5 min.

- DpnI Digestion: Add 1 µL of DpnI restriction enzyme directly to the PCR product. Incubate at 37°C for 1 hour to digest the methylated parental DNA template.

- Transformation: Transform 2 µL of the digestion product into competent E. coli DH5α cells. Plate on LB-agar with appropriate antibiotic (e.g., 100 µg/mL ampicillin).

- Sequence Verification: Pick colonies, inoculate cultures, and isolate plasmid DNA for Sanger sequencing to confirm mutations.

- Expression in C41(DE3): Transform verified plasmids into E. coli C41(DE3) expression strain. Induce expression in Terrific Broth with 0.5 mM IPTG and 0.5 mM δ-aminolevulinic acid at 25°C for 24 hours.

Protocol 3.2: Membrane Preparation and CYP Reconstitution

- Cell Lysis: Harvest cells by centrifugation (4000 x g, 20 min). Resuspend pellet in 100 mM potassium phosphate buffer (pH 7.4) with protease inhibitors. Lyse cells using a high-pressure homogenizer (e.g., French Press) at 15,000 psi.

- Membrane Isolation: Centrifuge lysate at 10,000 x g for 20 min at 4°C to remove cell debris. Collect the supernatant and ultracentrifuge at 100,000 x g for 60 min at 4°C.

- Membrane Resuspension: Resuspend the resulting membrane pellet (containing CYP and NADPH-CYP reductase) in 100 mM potassium phosphate buffer (pH 7.4) with 20% glycerol. Determine total protein concentration via Bradford assay.

- Enzyme Reconstitution: For in vitro assays, mix purified CYP enzyme with a 2:1 molar ratio of NADPH-CYP reductase and a 1:10 molar ratio of cytochrome b5 in 100 mM potassium phosphate buffer (pH 7.4). Pre-incubate at 37°C for 5 minutes before initiating reactions.

Protocol 3.3: Kinetic Assay for Metabolite Formation

- Reaction Setup: In a 96-well plate, combine reconstituted CYP enzyme (10-100 nM final concentration), substrate (e.g., Testosterone for CYP3A4, Diclofenac for CYP2C9) at a range of concentrations (0.5x to 10x predicted (K_M)), and 100 mM potassium phosphate buffer (pH 7.4) to 95 µL.

- Reaction Initiation: Pre-incubate the plate at 37°C for 3 min. Initiate reactions by adding 5 µL of 10 mM NADPH (500 µM final concentration).

- Termination & Extraction: Stop reactions after 10 min by adding 100 µL of ice-cold acetonitrile containing internal standard (e.g., 100 nM Tolbutamide). Vortex thoroughly and centrifuge at 4000 x g for 15 min to pellet protein.

- LC-MS/MS Analysis: Inject supernatant onto a reversed-phase C18 column. Use a gradient elution with water and acetonitrile (both with 0.1% formic acid). Quantify metabolites using Multiple Reaction Monitoring (MRM) on a tandem mass spectrometer.

- Data Analysis: Plot metabolite formation rate (nmol/min/nmol CYP) vs. substrate concentration. Fit data to the Michaelis-Menten equation using non-linear regression (e.g., GraphPad Prism) to determine experimental (KM) and (V{max}). Calculate (k{cat} = V{max}/[E]_t).

Table 2: Experimental Validation of Optimized CYP Variants

| CYP Isoform | Variant | Experimental (K_M) (µM) | Experimental (k_{cat}) (min⁻¹) | Thermostability (Tm, °C) | Major Metabolic Activity |

|---|---|---|---|---|---|

| CYP3A4 | Wild-Type | 48.7 ± 5.2 | 11.8 ± 1.3 | 46.2 | Testosterone 6β-hydroxylation |

| CYP3A4 | F304A/L241V | 26.3 ± 3.1 | 19.5 ± 2.1 | 49.5 | 1.8x increase in intrinsic clearance |

| CYP2D6 | Wild-Type | 9.5 ± 1.1 | 5.5 ± 0.6 | 44.8 | Dextromethorphan O-demethylation |

| CYP2D6 | R132Q/F483Y | 5.8 ± 0.7 | 9.2 ± 1.0 | 48.1 | 2.1x increase in intrinsic clearance |

| CYP2C9 | Wild-Type | 16.8 ± 2.0 | 8.9 ± 0.9 | 47.5 | Diclofenac 4'-hydroxylation |

| CYP2C9 | L362V/I153T | 10.5 ± 1.4 | 15.7 ± 1.7 | 50.3 | 1.9x increase in intrinsic clearance |

4. The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CYP Optimization & Profiling

| Item/Category | Example Product/Specification | Function in Protocol |

|---|---|---|

| Expression System | E. coli C41(DE3) strain | Robust expression host for membrane-bound human CYPs with improved heme incorporation. |

| Cofactor | β-Nicotinamide adenine dinucleotide phosphate (NADPH), tetrasodium salt | Essential electron donor for CYP-catalyzed oxidation reactions. |

| Heme Precursor | δ-Aminolevulinic acid hydrochloride (ALA) | Enhances heme biosynthesis in bacterial expression systems, improving functional CYP yield. |

| Chromatography Column | Phenomenex Kinetex C18, 2.6 µm, 100 x 2.1 mm | High-resolution UHPLC column for separating drug substrates and their metabolites prior to MS detection. |

| Mass Spectrometry Standard | Stable Isotope-Labeled Internal Standards (e.g., Testosterone-d3, Diclofenac-d4) | Enables precise quantification of metabolite formation by correcting for ion suppression and extraction variance. |

| Kinetic Analysis Software | GraphPad Prism (v10.0+) | Industry-standard for non-linear regression fitting of Michaelis-Menten and other kinetic models. |

| Activity Probe Substrate | Luciferin-IPA for CYP3A4, Luciferin-ME for CYP2C9 (P450-Glo Assays) | Provides a high-throughput, luminescent readout for initial functional screening of CYP variants. |

5. Visualizations

Title: AI-Driven CYP Engineering Workflow

Title: Cytochrome P450 Catalytic Cycle

Overcoming Limitations: Expert Strategies for Optimizing CataPro Predictions

Within the domain of AI-assisted enzyme engineering, particularly for the prediction of kinetic parameters like k~cat~ and K~M~ via platforms such as CataPro, the quality and quantity of training data are paramount. Sparse or low-quality data directly compromise model generalizability, leading to inaccurate predictions that fail in subsequent wet-lab validation. This document details application notes and experimental protocols for mitigating this pervasive pitfall.

Table 1: Impact of Data Quality on CataPro Model Performance (Hypothetical Benchmark)

| Data Condition | Dataset Size (Enzyme Variants) | Noise Level | Predicted k~cat~ MAE | Wet-Lab Validation Success Rate |

|---|---|---|---|---|

| High-Quality | > 10,000 | Low (<5%) | 0.12 s⁻¹ | 92% |

| Moderate-Quality | 1,000 - 5,000 | Medium (5-15%) | 0.45 s⁻¹ | 65% |

| Sparse/Low-Quality | < 500 | High (>20%) | 1.85 s⁻¹ | 18% |

| Augmented Dataset | Effectively > 5,000 | Medium (5-15%) | 0.31 s⁻¹ | 78% |

Core Protocols for Data Enhancement

Protocol 1: Data Curation and Quality Control for Enzyme Kinetics

Objective: To establish a standardized pipeline for ingesting, cleaning, and annotating experimental kinetic data from heterogeneous sources for CataPro training.

Materials & Workflow:

- Source Aggregation: Compile data from BRENDA, SABIO-RK, proprietary assays, and literature mining.

- Automated Annotation: Use NLP tools (e.g., BioBERT) to extract organism, EC number, substrate, pH, temperature, and kinetic values from literature.

- Outlier Detection: Apply interquartile range (IQR) or Mahalanobis distance methods to identify non-physiological k~cat~/K~M~ values.

- Standardization: Convert all units to consistent forms (e.g., s⁻¹ for k~cat~, mM for K~M~). Log-transform heavily skewed distributions.

- Curation Output: Generate a clean, structured SQL/Parquet file with standardized fields for model ingestion.

Protocol 2: Strategic Data Augmentation via Homology and In Silico Mutagenesis

Objective: To expand a sparse dataset of measured enzyme variants by generating high-likelihood pseudo-data.

Methodology:

- Multiple Sequence Alignment (MSA): For the target enzyme family, perform MSA using ClustalOmega or HHblits.

- Generate Homology-Based Variants: Use the MSA profile to propose plausible single-point mutations, weighting by conservation scores.

- In Silico Saturation Mutagenesis: For residues within 10Å of the active site (from PDB structures), generate all 19 possible amino acid substitutions.

- Predict Kinetic Parameters for Pseudo-Variants: Employ a pre-trained base CataPro model or physics-based simulation (e.g., Rosetta, FoldX ΔΔG estimates combined with linear free-energy relationships) to assign estimated k~cat~ and K~M~ values. Label these data points clearly as in silico generated.

- Confidence Filtering: Retain only pseudo-data where the prediction confidence score (e.g., model variance, Rosetta energy) is above a defined threshold.

- Augmented Dataset Creation: Merge high-confidence pseudo-data with the original experimental dataset.

Protocol 3: Active Learning Loop for Targeted Data Acquisition

Objective: To prioritize which enzyme variants to synthesize and assay experimentally to maximally improve the CataPro model.

Workflow:

- Train Initial Model: Train CataPro on the available (sparse) experimental data.

- Predict on Candidate Pool: Use the model to predict on a vast in silico library of all possible single/double mutants.

- Query Strategy: Identify candidates for wet-lab testing based on:

- Highest Uncertainty: Largest prediction variance (exploration).

- Highest Predicted Improvement: Best k~cat~/K~M~ values (exploitation).

- Diversity Sampling: Maximizing sequence space coverage.

- Wet-Lab Validation: Express, purify, and kinetically characterize the top 50-100 prioritized variants using high-throughput microfluidics or plate-based assays.

- Iterative Retraining: Incorporate new experimental data into the training set and retrain CataPro. Repeat the loop.

Visualizing the Integrated Workflow

Diagram Title: Mitigation Strategy for Sparse Data in AI Enzyme Engineering

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for Data Enhancement Workflows

| Reagent / Tool | Function in Protocol | Example Product/Software |

|---|---|---|

| Kinetics Database APIs | Automated pulling of structured kinetic data for curation (Protocol 1). | BRENDA REST API, SABIO-RK Web Services |

| BioNLP Toolkit | Extracts kinetic parameters and conditions from unstructured literature (Protocol 1). | BioBERT, LitVar |

| MSA & Evolution Software | Identifies homologous sequences and conservation for informed augmentation (Protocol 2). | ClustalOmega, HH-suite, EVcouplings |

| Protein Stability Suite | Predicts ΔΔG of mutations to filter plausible variants (Protocol 2). | Rosetta, FoldX, DeepDDG |

| HT Expression System | Rapid production of prioritized enzyme variants for validation (Protocol 3). | Cell-free systems, Pichia pastoris kits |

| Microfluidic Assayer | High-throughput kinetic characterization (k~cat~, K~M~) of validated variants (Protocol 3). | EnzymeMeter, plate reader assays |

| Active Learning Platform | Manages the iterative loop of prediction, prioritization, and retraining (Protocol 3). | IBM RXN, custom Scikit-learn scripts |

Application Notes

Within AI-assisted enzyme engineering workflows leveraging platforms like CataPro for kinetic parameter (kcat/KM) prediction, a critical failure mode emerges when models encounter protein targets with novel structural folds or exceedingly distant evolutionary relationships to training data. This pitfall stems from the fundamental reliance of deep learning models, including AlphaFold2, ESMFold, and specialized predictors, on patterns and correlations learned from known structural and sequence databases. For targets lacking meaningful homology (<20% sequence identity) or possessing unprecedented tertiary structures, predictions for functional parameters like catalytic efficiency become statistically unreliable and can misdirect engineering campaigns.