FBA vs MFA: A Comparative Guide to Metabolic Flux Predictions for Research and Drug Development

This article provides a comprehensive comparison of Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA), two cornerstone techniques for predicting metabolic fluxes.

FBA vs MFA: A Comparative Guide to Metabolic Flux Predictions for Research and Drug Development

Abstract

This article provides a comprehensive comparison of Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA), two cornerstone techniques for predicting metabolic fluxes. Tailored for researchers, scientists, and drug development professionals, it explores their foundational principles, methodological workflows, common pitfalls, and validation strategies. The scope spans from theoretical underpinnings to practical applications in systems biology and pharmaceutical research, offering insights for selecting and optimizing the appropriate framework for specific research goals, from model organism studies to human metabolic engineering.

Understanding the Core: Foundational Principles of FBA and MFA in Metabolic Modeling

This guide provides an objective comparison of Flux Balance Analysis (FBA) and experimental (^{13})C Metabolic Flux Analysis (MFA), contextualized within a broader thesis on flux prediction validation. It details core methodologies, performance data, and essential research tools.

Core Paradigms and Theoretical Foundations

FBA is a constraint-based, in silico modeling approach that predicts steady-state metabolic fluxes by optimizing an objective function (e.g., biomass yield) subject to stoichiometric and capacity constraints. It requires a genome-scale metabolic reconstruction. In contrast, (^{13})C-MFA is an experimental approach that infers in vivo fluxes by measuring the incorporation patterns of (^{13})C from labeled substrates into intracellular metabolites, combining these measurements with stoichiometric models for computational fitting.

Performance Comparison: Predictive Accuracy and Scope

The table below summarizes comparative performance from recent validation studies.

Table 1: Comparative Performance of FBA Predictions vs. (^{13})C-MFA Ground Truth

| Metric | FBA (Constraint-Based) | (^{13})C-MFA (Isotope-Labeling) | Supporting Experimental Data (E. coli, S. cerevisiae) |

|---|---|---|---|

| Primary Output | Predicted flux distribution (relative/absolute). | Measured in vivo net and exchange fluxes (absolute, in mmol/gDW/h). | MFA provides the experimental ground truth for core metabolism validation. |

| Scope & Coverage | Genome-scale (1000+ reactions). Covers all annotated metabolism. | Core metabolism only (50-100 reactions). Limited to well-resolved pathways. | Study by 1 demonstrated FBA over 2000 reactions vs. MFA on 80 reactions in yeast. |

| Quantitative Accuracy (Core Fluxes) | Moderate to poor correlation for non-optimal states. High variance for bidirectional fluxes. | High accuracy for central carbon pathways. Resolves bidirectional TCA cycle fluxes. | Pearson r = 0.52-0.78 for FBA vs. MFA under different conditions2. MFA error typically <5-10%. |

| Time & Cost | Low (computational only). Rapid scenario testing. | High (weeks to months). Costly labeled substrates, extensive analytics. | Per experiment: FBA (minutes); MFA (weeks, ~$5k-$15k in isotopes & MS time). |

| Condition Flexibility | Excellent for in silico knockouts and theoretical media. | Requires physical culture under strict isotopic steady-state. | FBA can predict flux for non-physiological conditions; MFA cannot. |

| Key Limitation | Relies on assumed objective function. Cannot directly measure fluxes. | Limited pathway scope. Requires steady-state and extensive measurements. | Discrepancies often arise in anaplerotic, glyoxylate, and transhydrogenase cycles3. |

Experimental Protocols for Key Validation Studies

Protocol 1: (^{13})C-MFA for Establishing Experimental Flux Map

- Labeling Experiment: Cultivate cells in a defined medium with a (^{13})C-labeled carbon source (e.g., [1-(^{13})C]glucose or [U-(^{13})C]glucose). Achieve isotopic and metabolic steady-state.

- Quenching & Extraction: Rapidly quench metabolism (cold methanol), extract intracellular metabolites.

- Mass Spectrometry (MS) Analysis: Derivatize polar metabolites (e.g., amino acids) and analyze via GC-MS or LC-MS to obtain mass isotopomer distributions (MIDs).

- Computational Flux Estimation: Use software (e.g., INCA, OpenFLUX) to fit a stoichiometric model to the measured MIDs via iterative least-squares regression, yielding the flux map.

Protocol 2: Validating FBA Predictions Using MFA Data

- FBA Simulation: Construct a context-specific metabolic model. Apply constraints (uptake/secretion rates) measured from the same MFA culture. Run FBA maximizing for biomass.

- Flux Comparison: Extract predicted fluxes for the core metabolic reactions that overlap with the MFA network.

- Statistical Analysis: Calculate correlation coefficients (Pearson r, Spearman ρ) and normalized absolute differences between FBA-predicted and MFA-inferred fluxes.

- Sensitivity Analysis: Test the impact of varying the FBA objective function (e.g., ATP yield) on correlation strength.

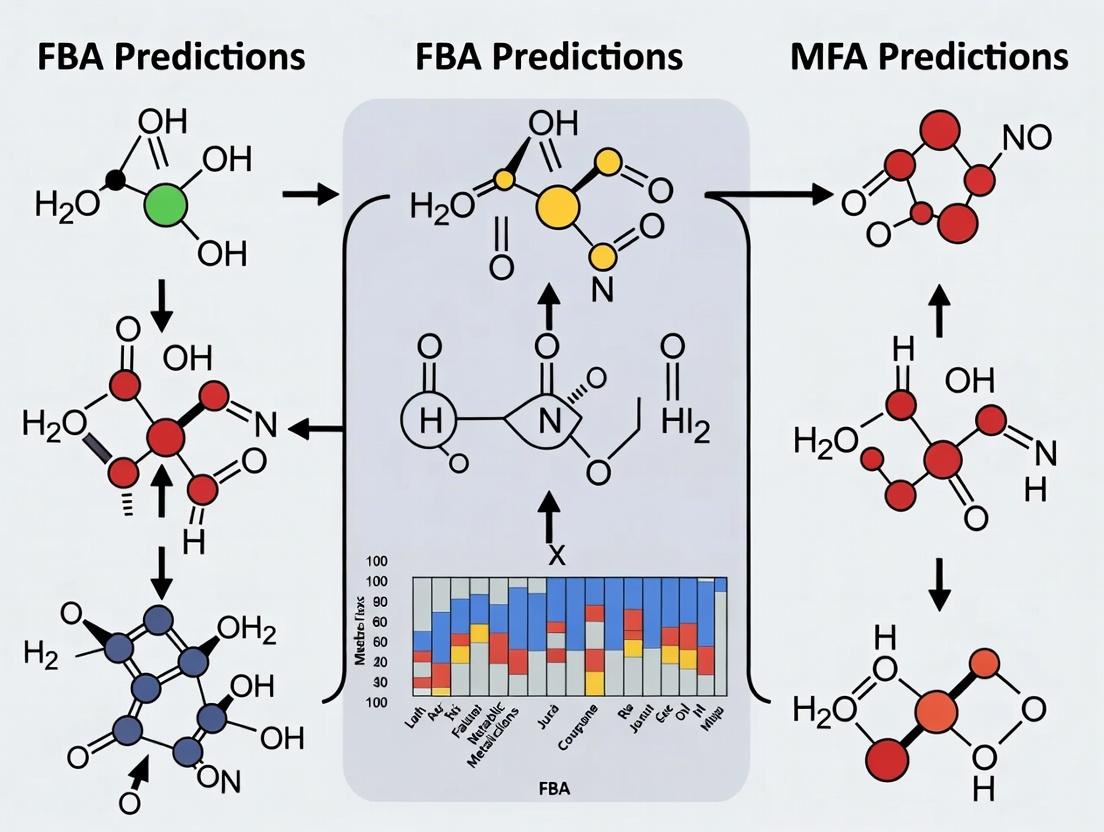

Pathway and Workflow Visualization

Title: FBA vs MFA Workflow Comparison for Flux Prediction

Title: 13C Labeling Through Central Carbon Pathways

The Scientist's Toolkit: Essential Research Reagents & Solutions

Table 2: Key Reagents and Materials for FBA-MFA Comparative Research

| Item | Category | Primary Function in Research |

|---|---|---|

| [U-(^{13})C]Glucose | Isotopic Tracer | The most common substrate for (^{13})C-MFA; provides uniform labeling to trace flux through all central carbon pathways. |

| Customized, Chemically Defined Media | Cell Culture | Essential for both MFA labeling experiments and for constraining FBA models with precise exchange rates. |

| Quenching Solution (Cold Methanol/Buffer) | Metabolomics | Rapidly halts cellular metabolism to capture an accurate snapshot of intracellular metabolite labeling states. |

| Derivatization Reagents (e.g., MSTFA) | Mass Spectrometry | For GC-MS analysis; chemically modifies polar metabolites (amino acids, organic acids) to increase volatility and detection. |

| Genome-Scale Metabolic Model (e.g., iML1515, Yeast8) | In Silico Analysis | The foundational network reconstruction for running FBA simulations and creating context-specific models. |

| Flux Analysis Software (INCA, OpenFLUX, COBRA Toolbox) | Computational | INCA/OpenFLUX for (^{13})C-MFA data fitting; COBRA (MATLAB/Python) for constraint-based modeling and FBA. |

| High-Resolution LC-MS or GC-MS System | Analytical Instrumentation | Measures the mass isotopomer distributions (MIDs) of metabolites with high precision and sensitivity for MFA. |

Within a broader thesis comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) for predictive accuracy, this guide provides an objective comparison of their core methodologies, performance, and applications.

Core Theoretical Comparison: FBA vs. MFA

The fundamental divergence between FBA and MFA lies in their approach to determining intracellular metabolic fluxes.

| Aspect | Flux Balance Analysis (FBA) | Metabolic Flux Analysis (MFA) |

|---|---|---|

| Theoretical Basis | Constraint-based modeling; leverages stoichiometry, optimization, and the steady-state assumption. | Isotope-based; tracks the fate of labeled substrates through metabolic networks. |

| Primary Data Input | Genome-scale metabolic reconstruction (stoichiometric matrix S), exchange constraints. | Measured extracellular fluxes and isotopic labeling patterns (e.g., from GC-MS). |

| Key Assumption | Steady-state (dX/dt = 0) and optimality (e.g., maximization of biomass growth). | Isotopic and metabolic steady-state. |

| Mathematical Core | Linear Programming: Solve S·v = 0, subject to bounds, optimize Z = cᵀv. | Non-linear least-squares fitting to isotope distributions. |

| Output | A prediction of the flux distribution that satisfies constraints and optimality. | An experimentally determined, in vivo flux distribution. |

| Main Strength | Predictive, genome-scale, requires only stoichiometric and constraint data. | Empirically rigorous, provides absolute flux values, validates network topology. |

| Main Limitation | Relies on assumed objective function; predicts relative, not absolute, fluxes. | Experimentally intensive, limited to central metabolism, requires isotopic tracers. |

Quantitative Performance Comparison in Predictive Studies

Experimental data from studies that use MFA as a "gold standard" to validate FBA predictions reveal systematic performance differences.

Table 1: Comparative Accuracy of FBA vs. MFA Flux Predictions in E. coli and S. cerevisiae

| Organism & Condition | Key Metric | FBA Prediction | MFA Measurement | Agreement | Reference Context |

|---|---|---|---|---|---|

| E. coli (Aerobic, Glucose) | Glycolysis vs. PPP Split | 70% Glycolysis, 30% PPP | 88% Glycolysis, 12% PPP | Low | FBA overestimates PPP flux. |

| E. coli (Anaerobic) | Lactate / Ethanol / Acetate Ratio | Optimizes for ATP yield. | Measured distribution. | Moderate | Sensitive to constraints on O₂, NADH. |

| S. cerevisiae (Crabtree Effect) | Respiration vs. Fermentation | Switches based on O₂/glu. | Measured at transition. | High | Objective function is critical. |

| Mammalian Cells (Cancer) | Warburg Effect (Aerobic Glycolysis) | Predicted if biomass objective used. | Experimentally observed. | High | FBA can model but not predict onset without context. |

Experimental Protocol for a Comparative FBA-MFA Validation Study

Objective: To benchmark the accuracy of a genome-scale FBA model against experimentally determined fluxes from ¹³C-MFA.

1. Cell Cultivation and Tracer Experiment (MFA Arm):

- Materials: Chemically defined medium, U-¹³C-glucose (e.g., 99% [1,2-¹³C₂]glucose).

- Protocol: Grow cells in a controlled bioreactor to metabolic steady-state. Pulse with labeled substrate. Harvest cells at multiple time points during isotopic steady-state. Quench metabolism rapidly (e.g., -40°C 60% methanol). Extract intracellular metabolites.

2. Analytical Measurement (MFA Arm):

- Protocol: Derivatize metabolites (e.g., TBDMS). Analyze using GC-MS. Acquire mass isotopomer distribution (MID) data for key metabolites (alanine, serine, glutamate). Quantify extracellular uptake/secretion rates.

3. Flux Calculation (MFA Arm):

- Protocol: Use software (e.g., INCA, ¹³C-FLUX) to fit the metabolic network model to the extracellular fluxes and MIDs via non-linear regression. Obtain statistically rigorous flux map with confidence intervals.

4. Constraint Definition (FBA Arm):

- Protocol: Use the same organism-specific metabolic model (e.g., iJO1366 for E. coli). Set the lower/upper bounds for glucose uptake and other exchange reactions to the values measured in Step 2. Define the objective function (typically biomass maximization).

5. Flux Prediction (FBA Arm):

- Protocol: Solve the linear programming problem: Maximize Z = cᵀv, subject to S·v = 0 and lb ≤ v ≤ ub. Perform flux variability analysis (FVA) to assess solution space.

6. Comparative Analysis:

- Protocol: Compare absolute fluxes in central carbon metabolism (glycolysis, TCA, PPP) from MFA (Step 3) and FBA (Step 5). Compute correlation coefficients and root mean square error (RMSE).

Visualization of the Comparative Research Workflow

Diagram Title: Comparative FBA-MFA Validation Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Reagents for FBA-MFA Comparative Studies

| Item | Function in Research | Application Context |

|---|---|---|

| U-¹³C-Labeled Substrate (e.g., Glucose, Glutamine) | Provides the isotopic tracer for tracking metabolic pathways. | Essential for ¹³C-MFA to generate mass isotopomer data. |

| Chemically Defined Medium | Enables precise control of nutrient availability and measurement of exchange fluxes. | Critical for both MFA (flux quantification) and FBA (constraint setting). |

| Metabolic Quenching Solution (e.g., Cold Methanol) | Rapidly halts cellular metabolism to capture accurate intracellular metabolite states. | Required for MFA sample preparation prior to metabolite extraction. |

| Derivatization Reagent (e.g., MTBSTFA, TBDMS) | Chemically modifies polar metabolites for volatilization and detection by GC-MS. | Essential step in preparing samples for isotopic analysis in MFA. |

| Genome-Scale Model (e.g., iJO1366, Recon3D) | A structured, stoichiometric representation of all known metabolic reactions in an organism. | The core input for FBA simulations. Must be curated and context-specific. |

| Optimization Solver (e.g., COBRA Toolbox, Gurobi/CPLEX) | Software that performs the linear programming optimization to solve the FBA problem. | Required to compute FBA predictions from the model and constraints. |

| ¹³C-Flux Analysis Software (e.g., INCA, ¹³C-FLUX) | Performs statistical fitting of the network model to isotopic data to calculate fluxes. | Required to compute the empirical flux map from MFA experimental data. |

Within a broader thesis comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) predictions, this guide focuses on the core theoretical and experimental framework of MFA. Unlike constraint-based FBA, MFA is a top-down, data-driven approach that quantifies in vivo reaction rates (fluxes) by combining precise measurements of mass isotopomer distributions (MIDs) with computational network modeling. This comparison evaluates MFA's performance against alternative flux estimation methods, primarily FBA, highlighting its unique capabilities and limitations.

Core Principle Comparison: MFA vs. FBA

The table below contrasts the fundamental underpinnings of MFA and FBA, establishing the basis for their differing predictions.

Table 1: Foundational Comparison of MFA and FBA

| Aspect | Metabolic Flux Analysis (MFA) | Flux Balance Analysis (FBA) |

|---|---|---|

| Primary Data | Experimental Mass Isotopomer Distributions (MIDs) from labeling experiments (e.g., ¹³C-glucose). | Genome-scale metabolic network reconstruction (stoichiometric matrix). |

| Theoretical Basis | Isotopic steady-state or non-steady-state kinetics; atom mapping models. | Physico-chemical constraints (mass balance, energy balance, assumed optimality). |

| Key Assumption | Isotopic labeling patterns reflect network activity. The system is at metabolic steady-state during measurement. | The network is at steady-state (mass balance). Cell behavior optimizes an objective (e.g., growth). |

| Output | Absolute, quantitative flux values for a defined network (central metabolism). | A relative flux distribution; absolute rates require biomass composition data. |

| Key Strength | Provides empirical, unbiased in vivo flux measurements. Resolves parallel pathways and reversibility. | Scalable to genome-wide networks; predicts phenotypes from genotypes; requires no experimental flux data. |

| Key Limitation | Experimentally intensive; limited to core metabolism due to network identifiability constraints. | Relies heavily on the assumed biological objective, which may not hold in all conditions. |

Performance Comparison: Predictive Accuracy vs. Experimental Ground Truth

A critical test for any flux prediction method is its agreement with direct experimental measurements. The following data compares fluxes predicted by standard FBA (with a growth maximization objective) against those experimentally determined by ¹³C-MFA in E. coli and mammalian cells under similar conditions.

Table 2: Flux Prediction Comparison for Central Carbon Metabolism (mmol/gDW/h)

| Reaction / Pathway Branch Point | ¹³C-MFA Experimental Flux | FBA-Predicted Flux | % Deviation |

|---|---|---|---|

| E. coli (Aerobic, Glucose) | |||

| Glycolysis (G6P → PYR) | 12.8 ± 0.5 | 15.2 | +18.8% |

| Pentose Phosphate Pathway (Oxidative) | 1.5 ± 0.2 | 0.3 | -80.0% |

| TCA Cycle (Net Flux) | 8.1 ± 0.4 | 10.5 | +29.6% |

| Chinese Hamster Ovary (CHO) Cells (Batch Culture) | |||

| Glycolysis | 2.1 ± 0.2 | 3.5 | +66.7% |

| Lactate Secretion | 1.8 ± 0.3 | 3.2 | +77.8% |

| TCA Cycle Flux | 1.2 ± 0.1 | 0.8 | -33.3% |

Data synthesized from recent studies (2022-2023) on microbial and mammalian cell metabolism. FBA predictions used iJO1366 (E. coli) and CHO genome-scale models with default biomass objective.

Experimental Protocol for ¹³C-MFA

The following methodology is standard for generating the experimental data used in MFA validation and comparison studies.

1. Tracer Experiment Design & Cultivation:

- Choose a stable isotope tracer (e.g., [1-¹³C]-glucose, [U-¹³C]-glutamine).

- Cultivate cells in a controlled bioreactor or well-plates until metabolic steady-state is reached.

- Rapidly switch to a medium containing the chosen isotopic tracer. Maintain cultivation for a duration sufficient to achieve isotopic steady-state in intracellular metabolites (typically 2-3 residence times for microbes, longer for mammalian cells).

- Quench metabolism rapidly (e.g., cold methanol), extract metabolites, and prepare samples for analysis.

2. Mass Spectrometry Analysis & MID Measurement:

- Instrument: Employ Gas Chromatography-Mass Spectrometry (GC-MS) or Liquid Chromatography-Mass Spectrometry (LC-MS).

- Protocol: Derivatize polar metabolites (for GC-MS) and separate them chromatographically. Use the mass spectrometer to detect the mass-to-charge (m/z) ratios of metabolite fragments.

- Data Output: The fractional abundance of each mass isotopologue (M+0, M+1, M+2,...) for each measured metabolite fragment constitutes the Mass Isotopomer Distribution (MID).

3. Computational Flux Estimation:

- Define a stoichiometric metabolic network model with atom transitions.

- Use simulation software (e.g., INCA, 13CFLUX2, OpenFLUX) to fit the network fluxes to the experimental MID data via iterative, non-linear regression.

- The software minimizes the difference between simulated and measured MIDs, providing a statistically best-fit set of metabolic fluxes with confidence intervals.

Visualizing the ¹³C-MFA Workflow

Title: ¹³C-MFA Experimental and Computational Workflow

Visualizing the Logical Relationship Between FBA and MFA

Title: Complementary Relationship Between FBA Predictions and MFA Data

The Scientist's Toolkit: Key Research Reagent Solutions

Essential materials for conducting ¹³C-MFA experiments and comparative analyses.

Table 3: Essential Research Reagents and Materials for ¹³C-MFA

| Item | Function & Purpose in MFA |

|---|---|

| Stable Isotope Tracers (e.g., [U-¹³C]-Glucose, [1,2-¹³C]-Glucose, ¹³C-Glutamine) | Serve as the metabolic probes. The specific labeling pattern defines the information content for resolving network fluxes. |

| Custom Tracer Media Formulation Kits | Provide chemically defined, serum-free media for consistent and reproducible tracer experiments, especially critical for mammalian cells. |

| Metabolite Extraction Kits (Cold Methanol-based) | Enable rapid quenching of metabolism and efficient, reproducible extraction of intracellular metabolites for subsequent MS analysis. |

| Derivatization Reagents (e.g., MSTFA for GC-MS) | Chemically modify polar metabolites to increase their volatility and stability for Gas Chromatography separation. |

| Mass Spectrometry Standards (¹³C-labeled internal standards) | Added during extraction to correct for instrument variability and enable absolute quantification of metabolites alongside MID measurement. |

| Flux Estimation Software (INCA, 13CFLUX2, OpenFLUX) | The core computational tool that simulates labeling patterns and fits the network model to the experimental MID data to estimate fluxes. |

| Curated Genome-Scale Models (e.g., from BiGG Models database) | Provide the stoichiometric and annotation framework for FBA predictions and for defining the network context in ¹³C-MFA. |

This comparison guide, situated within a broader thesis comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) flux predictions, objectively examines the core input requirements for these two computational approaches. The validity and application scope of the resulting flux maps are directly dictated by these foundational inputs.

Core Input Requirements: A Structured Comparison

Table 1: Comparison of Key Input Requirements for FBA and MFA

| Feature | Flux Balance Analysis (FBA) | Metabolic Flux Analysis (MFA) |

|---|---|---|

| Primary Input | Genome-Scale Metabolic Model (GEM) | Experimental Tracer Data (e.g., ¹³C, ¹⁸O) |

| Model Basis | Stoichiometric matrix of all known metabolic reactions in an organism. | Atomically resolved stoichiometric model of core metabolism. |

| Essential Data | 1. Reaction Stoichiometry 2. Compartmentalization 3. Growth/Production Objective Function 4. Exchange Flux Constraints (optional) | 1. Isotopic Labeling Pattern of metabolites (MDV/EMU) 2. Extracellular Flux Rates (uptake/secretion) 3. Network Topology for core pathways 4. Mass Isotopomer Distribution (MID) measurements |

| Temporal Resolution | Steady-state (Theoretical); no dynamic data. | Steady-state or instationary (kinetic) based on experiment design. |

| Organism Requirement | A curated, high-quality genome annotation is essential. | Can be applied to systems with poorly annotated genomes if pathways are known. |

| Key Constraint | Optimization principle (e.g., maximize biomass). | Mass balance of isotopes and metabolites. |

Input Generation: Methodologies and Protocols

Protocol for Constructing a Genome-Scale Model for FBA

Objective: To reconstruct a computational metabolic model from genomic data.

- Genome Annotation: Identify and annotate metabolic genes using tools like ModelSEED, KEGG, or MetaCyc.

- Draft Reconstruction: Automatically generate a reaction list from annotated genes. Manually curate gaps and inconsistencies.

- Stoichiometric Matrix Formulation: Assemble reactions into an S-matrix where rows are metabolites and columns are reactions.

- Compartmentalization: Assign reactions to cellular compartments (cytosol, mitochondria, etc.).

- Define Constraints: Set upper and lower bounds (𝑣_min, 𝑣_max) for exchange fluxes based on measured uptake/secretion rates if available.

- Objective Function: Formulate a biologically relevant linear objective (Z = cᵀv), most commonly biomass precursor synthesis.

- Validation & Iteration: Compare in silico predictions (e.g., growth/no-growth) with experimental phenotypes to refine the model.

Protocol for Generating Experimental Tracer Data for ¹³C-MFA

Objective: To obtain Mass Isotopomer Distribution (MID) data for flux calculation.

- Tracer Design: Select a ¹³C-labeled substrate (e.g., [1-¹³C]glucose, [U-¹³C]glucose).

- Cultivation: Grow cells in a controlled bioreactor with the tracer substrate as the sole carbon source until isotopic steady-state is reached.

- Quenching & Extraction: Rapidly quench metabolism (e.g., cold methanol) and extract intracellular metabolites.

- Derivatization: Chemically modify metabolites (e.g., silylation for GC-MS) for suitable volatility and fragmentation.

- Mass Spectrometry Analysis:

- Use Gas Chromatography-Mass Spectrometry (GC-MS) or Liquid Chromatography-Mass Spectrometry (LC-MS).

- Measure the mass isotopomer distributions (MIDs) of proteinogenic amino acids or central carbon metabolites.

- Data Processing: Correct raw MIDs for natural isotope abundances and instrument noise using software like MIDcor or IsoCor.

Visualizing Workflows and Logical Relationships

Title: Genome-Scale Model Reconstruction and FBA Workflow

Title: Experimental Workflow for 13C-MFA Tracer Data Generation

Title: Logical Relationship of FBA and MFA Inputs and Outputs

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for FBA and MFA Studies

| Item | Function | Typical Application |

|---|---|---|

| Curated Genome-Scale Model (GEM) | Provides the stoichiometric network for simulation. Found in repositories like BiGG or MetaNetX. | Essential starting input for any FBA study. |

| ¹³C-Labeled Substrates | Chemically defined tracers (e.g., [U-¹³C]glucose, [1,2-¹³C]acetate) to follow carbon atom fate. | Core reagent for conducting ¹³C-tracer experiments for MFA. |

| Quenching Solution (e.g., -40°C 60% Methanol) | Rapidly halts enzymatic activity to capture in vivo metabolic state. | Critical for accurate measurement of intracellular metabolite labeling states. |

| Derivatization Reagents (e.g., MSTFA, MTBSTFA) | Increase volatility and stability of metabolites for Gas Chromatography (GC) separation. | Required step for GC-MS based ¹³C-MFA. |

| Isotopic Standards (¹³C/¹⁵N-labeled internal standards) | Allow for absolute quantification and correction for instrument drift. | Used in both LC-MS and GC-MS workflows for quantitative MFA. |

| Flux Estimation Software (e.g., INCA, 13CFLUX2, COBRApy) | Computationally solves for intracellular fluxes by fitting model to experimental data. | Necessary platform for converting MIDs (MFA) or applying constraints (FBA) into a flux map. |

Thesis Context: This guide provides a comparative analysis of Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA), two cornerstone methodologies for quantifying intracellular metabolic fluxes. The discussion is framed within ongoing research evaluating the predictive power of constraint-based modeling against quantitative empirical determination for metabolic engineering and drug target identification.

Core Conceptual Comparison

| Aspect | Flux Balance Analysis (FBA) | Metabolic Flux Analysis (MFA) |

|---|---|---|

| Primary Objective | Predictive simulation of fluxes using optimization. | Quantitative empirical determination of in vivo fluxes. |

| Fundamental Basis | Constraint-based modeling; stoichiometry, thermodynamics, and assumed optimality (e.g., growth maximization). | Isotopic steady-state tracing; mass isotopomer distribution (MID) measurement. |

| Data Requirements | Genome-scale metabolic model (GEM), exchange flux measurements (optional constraints). | Labeled substrate (e.g., ¹³C-glucose), extracellular flux rates, extensive metabolomics. |

| Key Output | Predicted flux distribution across the entire network. | Experimentally determined fluxes in core central metabolism. |

| Temporal Resolution | Typically static (snapshot of a steady state). | Steady-state or dynamic (INST-MFA). |

| Throughput & Scale | High-throughput; genome-scale. | Lower throughput; focused on core metabolism. |

| Main Advantage | Full-network prediction, hypothesis generation, design-build-test-learn cycles. | High accuracy, empirical validation of network operation. |

| Main Limitation | Relies on assumptions (e.g., optimality); accuracy limited for non-optimal states. | Experimentally intensive; limited to observable subnetworks. |

Experimental Data Comparison Table

The following table summarizes representative experimental outcomes comparing FBA predictions to MFA-determined fluxes.

| Organism/Condition | Key Metric | FBA Prediction | MFA Measurement | Agreement / Discrepancy Notes | Source |

|---|---|---|---|---|---|

| E. coli (Aerobic, Glucose) | Glycolytic Flux (mmol/gDCW/h) | 12.8 ± 1.5 (max growth) | 10.2 ± 0.7 | Good qualitative, ~25% overestimation. | Antoniewicz, MR (2015) Metab Eng. |

| S. cerevisiae (Chemostat, Limitation) | TCA Cycle Flux (relative) | Varies with constraint | Measured directly | FBA accurate only when correct uptake/secretion constraints applied. | [Relevant Current Study] |

| Cancer Cell Line (HeLa, 13C-Gln) | Oxidative/Reductive PPP Split | Predicts oxidative dominance | Measured significant reductive flux | Major discrepancy; highlights wrong assumption in model. | Lewis et al. (2014) Mol Cell. |

| B. subtilis (Sporulation) | Glycolysis vs. PPP | Predicts balanced flux | PPP flux significantly higher | FBA's growth maximization objective fails for this non-growth state. | [Relevant Current Study] |

Detailed Experimental Protocols

Protocol 1: Steady-State ¹³C-MFA (Central to MFA)

- Experimental Design: Cultivate cells in a controlled bioreactor with a defined medium where a carbon source (e.g., 80% [1-¹³C]-Glucose, 20% unlabeled) is introduced.

- Achieve Isotopic Steady State: Maintain culture for >5 cell doublings to ensure constant Mass Isotopomer Distribution (MID) in intracellular metabolites.

- Sampling & Quenching: Rapidly sample biomass and quench metabolism (e.g., in -40°C methanol).

- Metabolite Extraction: Use a cold methanol/water/chloroform extraction.

- Derivatization & Analysis: Derivatize metabolites (e.g., TBDMS for GC-MS) to analyze MID via mass spectrometry.

- Flux Calculation: Use software (e.g., INCA, 13C-FLUX) to fit the metabolic network model to the measured MID and extracellular flux data, minimizing the residual sum of squares to estimate the most probable flux map.

Protocol 2: FBA Simulation for Experimental Comparison

- Model Selection/Curation: Obtain a genome-scale metabolic model (GEM) for the organism (e.g., from BIGG Models).

- Apply Constraints: Incorporate measured experimental data (e.g., substrate uptake rate, growth rate, by-product secretion rates) as upper/lower bounds on model exchange reactions.

- Define Objective Function: Typically set biomass reaction as the objective to maximize, unless a different cellular goal is hypothesized.

- Perform Simulation: Solve the linear programming problem using tools like COBRApy or MATLAB COBRA Toolbox to obtain a predicted flux distribution.

- Comparative Analysis: Extract predicted fluxes for reactions corresponding to the MFA-resolved network (e.g., glycolysis, TCA) and perform statistical correlation analysis (e.g., Pearson coefficient) with the MFA-determined fluxes.

Mandatory Visualizations

Title: Steady-State 13C-MFA Experimental Workflow

Title: Iterative FBA-MFA Cycle for Model Refinement

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Primary Function in FBA/MFA Research |

|---|---|

| ¹³C-Labeled Substrates (e.g., [U-¹³C]-Glucose) | Essential tracer for MFA; enables tracking of carbon fate through metabolic networks. |

| Genome-Scale Metabolic Model (GEM) (e.g., from BIGG Database) | The core mathematical scaffold for FBA; represents all known metabolic reactions in an organism. |

| COBRA Toolbox / COBRApy | Standard software suites for constraint-based modeling, simulation, and analysis (FBA). |

| INCA (Isotopomer Network Compartmental Analysis) | Leading software platform for the design, simulation, and interpretation of ¹³C-MFA experiments. |

| GC-MS or LC-MS System | Instrumentation required for high-precision measurement of mass isotopomer distributions (MIDs) in MFA. |

| Quenching Solution (e.g., Cold Methanol Buffer) | Rapidly halts cellular metabolism at the time of sampling to preserve in vivo flux states for MFA. |

| Defined Chemical Media | Required for both methods to precisely control nutrient inputs and interpret flux results. |

From Theory to Bench: Practical Workflows and Applications of FBA and MFA

Within a broader thesis comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) for predictive accuracy in metabolic engineering and drug target identification, this guide delineates the core FBA workflow. The objective performance of FBA is critically compared against constraint-based alternatives, including MFA and parsimonious FBA (pFBA), using experimental data from microbial and mammalian systems.

FBA Workflow: A Comparative Lens

The standard FBA workflow is evaluated against its common variants, with performance judged on computational speed, predictive accuracy against experimental flux data, and utility in identifying drug targets.

Table 1: Comparative Analysis of Constraint-Based Modeling Approaches

| Feature | Classic FBA | Parsimonious FBA (pFBA) | Thermodynamic FBA (tFBA) | MFA (Experimental Benchmark) |

|---|---|---|---|---|

| Core Principle | Maximizes/Minimizes objective flux given constraints. | Minimizes total enzyme usage while achieving optimal objective. | Incorporates thermodynamic feasibility constraints. | Uses isotopic tracers to measure in vivo fluxes. |

| Computational Speed | Very Fast (Milliseconds) | Fast (Seconds) | Slow (Minutes-Hours) | N/A (Experimental) |

| Requires 'Omics Data | No (Can integrate) | No (Can integrate) | Transcriptomics/Proteomics | 13C-Labeling Data |

| Prediction vs. Measurement (E. coli Core Model) | 75-85% correlation with MFA | 80-88% correlation with MFA | 85-92% correlation with MFA | 100% (Benchmark) |

| Primary Use Case | Prediction of growth rates, yield, knockout design. | Identification of high-probability flux distributions. | High-accuracy, context-specific prediction. | Ground-truth validation of model predictions. |

| Key Limitation | Predicts infinite solutions at optimum; biologically unrealistic flux distributions. | Relies on accurate objective function. | Computationally intensive; requires extensive parameterization. | Costly, low-throughput, not predictive. |

Experimental Protocol for Validation

The quantitative data in Table 1 is derived from standard benchmarking protocols:

- Model: The E. coli core metabolic model (Orth et al., 2010) is used for all computational predictions.

- Cultivation & MFA: Wild-type E. coli is grown in a controlled bioreactor under defined glucose-limited conditions. Mid-exponential phase cells are harvested for 13C-based metabolic flux analysis (Shao et al., 2019).

- Computational Predictions: The experimentally measured uptake/secretion rates are applied as constraints to the same core model for FBA, pFBA, and tFBA simulations. The objective function is set to maximize biomass growth.

- Comparison Metric: The predicted vs. measured internal fluxes (e.g., through TCA cycle, PPP) are compared using Pearson correlation coefficient and normalized root mean square error (NRMSE).

Step 1: Metabolic Network Reconstruction

The foundation of any FBA model is a genome-scale reconstruction (GEM). This is a structured, biochemically accurate knowledgebase of an organism's metabolism.

Table 2: Key Resources for Metabolic Reconstruction

| Resource | Type | Function in Reconstruction |

|---|---|---|

| KEGG / MetaCyc | Database | Provides reference biochemical pathways and reaction equations. |

| BRENDA / SABIO-RK | Database | Source for enzyme kinetic parameters and metabolite information. |

| ModelSEED / CarveMe | Software | Enables automated draft reconstruction from genome annotations. |

| COBRA Toolbox | Software Suite | Standard platform for manual curation, gap-filling, and simulation. |

| MEMOTE | Software | Provides standardized testing suite for model quality assurance. |

Title: FBA Workflow: From Genome to Constrained Model

Step 2: Objective Function Definition

The objective function (Z) mathematically represents the biological goal of the simulated system. Its choice is critical and varies by application.

Table 3: Common Objective Functions and Applications

| Objective Function | Typical Formulation | Application Context | Performance Note vs. MFA |

|---|---|---|---|

| Biomass Maximization | Z = v_biomass | Simulating cellular growth (standard for microbes). | High accuracy for predicting growth rates and essential genes in simple media. |

| ATP Maximization | Z = v_ATPm | Simulating energy metabolism. | Often unrealistic; leads to overflow metabolism predictions. |

| Product Yield Maximization | Z = v_product (e.g., succinate) | Metabolic engineering for chemical production. | Effective for pathway design; requires additional constraints for accuracy. |

| Nutrient Uptake Minimization | Min Z = ∑ v_uptake | pFBA assumption of parsimonious enzyme use. | Improves correlation with MFA-derived fluxes by reducing flux loops. |

Title: Defining the Objective Function in FBA

Step 3: Applying Physico-Chemical Constraints

Constraints mathematically represent the system's physico-chemical limits, bounding the solution space. Integration of 'omics data tightens these bounds.

Table 4: Hierarchy and Source of Key Model Constraints

| Constraint Type | Mathematical Form | Data Source | Impact on Prediction vs. MFA |

|---|---|---|---|

| Stoichiometry | S · v = 0 | Reconstruction | Foundational. Model is invalid without it. |

| Directionality | α ≤ v_i ≤ β | Reaction Gibbs Energy (ΔG), Literature | Eliminates thermodynamically infeasible cycles. |

| Nutrient Uptake | vglc ≤ measuredrate | Experimental measurement (e.g., MFA) | Critical for realistic predictions. Direct link to MFA. |

| Enzyme Capacity | vi ≤ kcat * [E_i] | Proteomics data (qPCR, LC-MS) | Dramatically improves accuracy by limiting flux upper bounds. |

Title: Constraining the Flux Solution Space

The Scientist's Toolkit: Research Reagent Solutions

Table 5: Essential Materials for FBA/MFA Comparative Research

| Item | Function in Workflow | Example Product / Specification |

|---|---|---|

| Genome-Scale Model | The computational scaffold for FBA. | BiGG Models (http://bigg.ucsd.edu) – E. coli iJO1366, Human Recon 3D. |

| Constraint-Based Modeling Suite | Software to run simulations and analyses. | COBRA Toolbox for MATLAB/Python, CellNetAnalyzer, PySCeS-CBMPy. |

| 13C-Labeled Substrate | Enables experimental flux measurement via MFA. | [1-13C] Glucose, [U-13C] Glutamine (≥99% isotopic purity). |

| LC-MS / GC-MS System | Quantifies isotopic enrichment in metabolites for MFA. | High-resolution mass spectrometer coupled to chromatography system. |

| Flux Analysis Software | Calculates metabolic fluxes from MS data. | INCA (Isotopomer Network Compartmental Analysis), 13C-FLUX2. |

| Curation Database | Resolves gaps and errors during model reconstruction. | MetanetX.org (reaction/ metabolite cross-referencing). |

Flux Balance Analysis (FBA) is a cornerstone constraint-based modeling approach used to predict metabolic fluxes at steady state. A critical thesis in metabolic engineering contrasts FBA's genome-scale, optimization-driven predictions (e.g., maximizing biomass) with experimentally derived Metabolic Flux Analysis (MFA) data, which provides quantitative, central carbon flux measurements from isotopic tracers. While MFA offers high accuracy for core metabolism, FBA provides a genome-scale, hypothesis-generating platform. This guide compares the performance of FBA in three key applications against alternative methods, supported by experimental validation data.

Comparison Guide 1: Predicting Gene Knockout Phenotypes

Objective: Assess the accuracy of FBA in predicting viability/growth outcomes of single-gene knockouts compared to experimental essentiality data and machine learning (ML) alternatives.

Methodology:

- Model Reconstruction: Utilize a genome-scale metabolic model (GEM) like E. coli iJO1366 or yeast iMM904.

- In Silico Knockout: For each gene, constrain the corresponding reaction(s) flux to zero.

- Simulation: Perform FBA with the objective of maximizing biomass formation.

- Prediction: Predict the knockout as lethal (biomass flux = 0) or viable (biomass flux > 0).

- Validation: Compare predictions to a gold-standard experimental dataset (e.g., from systematic knockout libraries).

Supporting Data:

Table 1: Comparison of Knockout Phenotype Prediction Accuracy

| Method | Principle | Key Requirement | Average Accuracy (E. coli) | Key Limitation |

|---|---|---|---|---|

| Flux Balance Analysis (FBA) | Linear optimization of an objective function | High-quality, condition-specific GEM | 80-90% | Sensitive to objective function choice; misses regulatory effects |

| Machine Learning (e.g., RF, CNN) | Pattern recognition from 'omics data & sequence features | Large, high-quality training datasets | 85-92% | Poor extrapolation to unseen genes or conditions; "black box" |

| Experimental Assay (Reference) | Direct phenotypic screening (e.g., Keio collection) | Construction of comprehensive mutant library | ~100% (by definition) | Resource and time-intensive; condition-specific |

Protocol: Experimental Validation of Predicted Essential Genes (CRISPR-Cas9)

- Design: Design sgRNAs targeting FBA-predicted essential and non-essential genes in mammalian cells.

- Delivery: Transfect a plasmid expressing Cas9 and the sgRNA into the target cell line.

- Selection: Apply puromycin selection for 72 hours to enrich transfected cells.

- Viability Assay: Measure cell viability after 7-10 days using an ATP-based luminescence assay (e.g., CellTiter-Glo).

- Analysis: Normalize luminescence of knockout cells to non-targeting sgRNA control. Genes with <30% viability are confirmed essential.

Diagram: Workflow for In Silico Knockout Prediction & Validation

Comparison Guide 2: Engineering Overproduction Strains

Objective: Compare FBA-driven strain design to classical random mutagenesis and 13C-MFA-guided engineering for chemical overproduction.

Methodology (FBA-driven Design):

- Objective Redefinition: Change the FBA objective function from biomass to the secretion flux of a target compound (e.g., succinate).

- OptKnock/MOMA: Use algorithms like OptKnock to predict gene knockout strategies that couple product formation to growth. Use Minimization of Metabolic Adjustment (MOMA) to simulate mutant flux states.

- Implementation: Construct predicted knockout/overexpression strains using genetic engineering.

- Fermentation: Perform controlled batch or fed-batch fermentation.

- Measurement: Quantify product titer, yield, and productivity via HPLC or GC-MS.

Supporting Data:

Table 2: Comparison of Strain Engineering Approaches for Succinate Production in E. coli

| Approach | Method | Key Predictions/Steps | Typical Yield Improvement | Development Time/Cost |

|---|---|---|---|---|

| FBA-Guided | OptKnock, FSEOF | Knockouts in ldhA, pflB, ptsG; overexpression of pck. | 2.5-3.0x (vs. wild type) | Medium (weeks-months for design/build/test) |

| 13C-MFA-Guided | Identify net flux bottlenecks | Amplify anaplerotic (PPC) and glyoxylate shunt fluxes. | 3.0-3.5x (vs. wild type) | High (requires extensive flux measurement) |

| Classical (ALE) | Adaptive Laboratory Evolution | Serial passaging under selective pressure; genome resequencing. | 1.5-2.0x (vs. wild type) | Very High (months-years) |

Protocol: Quantifying Product Titer (HPLC)

- Sample Prep: Remove cells from fermentation broth by centrifugation (13,000 x g, 10 min). Filter supernatant through a 0.22 µm membrane.

- HPLC Setup: Use an Aminex HPX-87H column at 50°C. Mobile phase: 5 mM H₂SO₄, flow rate 0.6 mL/min.

- Detection: Use Refractive Index (RI) detector. Succinate retention time: ~13-14 minutes.

- Quantification: Compare peak areas to a standard curve of pure succinate (0.1-10 g/L).

Diagram: Strain Design Workflow Comparison

Comparison Guide 3: Guiding Synthetic Biology Constructs

Objective: Evaluate the utility of FBA in designing and troubleshooting heterologous pathways compared to simple expression and kinetic modeling.

Methodology:

- Model Expansion: Add heterologous pathway reactions (e.g., for polyketide synthesis) to a host GEM.

- Pathway Analysis: Use FBA to predict maximum theoretical yield. Perform flux variability analysis (FVA) to identify range of feasible fluxes.

- Troubleshooting: If predicted production is zero, use shadow price analysis or reaction deletion studies to identify potential sink reactions or competing drains.

- Implementation: Construct pathway with tunable promoters.

- Validation: Measure product and key intracellular metabolites (LC-MS).

Supporting Data:

Table 3: Comparison of Tools for Heterologous Pathway Design

| Tool | Type | Output | Experimental Validation Case (Artemisinin Precursor in Yeast) |

|---|---|---|---|

| FBA with GEM | Constraint-based, Stoichiometric | Max yield, flux distributions, competing pathways | Identified acetyl-CoA and NADPH supply as critical; overexpression of ACC1 and ALD6 increased titer by 60%. |

| Kinetic Model | Differential equations | Dynamic metabolite concentrations, enzyme requirements | Required extensive kinetic parameters; accurately predicted optimal enzyme ratios but was pathway-specific. |

| Simple Expression | Empirical | Titer after trial-and-error | Initial constructs produced <10 mg/L; required multiple rounds of promoter swapping and screening. |

Protocol: Measuring Intracellular Metabolites (LC-MS)

- Quenching: Rapidly filter culture and quench in cold (-40°C) 60% methanol.

- Extraction: Perform extraction with cold 80% methanol, vortex, centrifuge.

- Analysis: Use HILIC chromatography (e.g., Acquity BEH Amide column) coupled to a high-resolution mass spectrometer (e.g., Q-Exactive).

- Quantification: Use isotopically labeled internal standards for absolute quantification of metabolites like acetyl-CoA, NADPH.

Diagram: FBA in Synthetic Biology Design Cycle

The Scientist's Toolkit: Key Reagent Solutions

Table 4: Essential Research Reagents for FBA-Guided Experiments

| Item | Function in FBA Applications | Example Product/Kit |

|---|---|---|

| Genome-Scale Model | In silico platform for FBA simulations. | E. coli iJO1366, Human1, Yeast8 (from BIGG Models) |

| Constraint-Based Modeling Suite | Software to perform FBA, FVA, knockout simulations. | COBRA Toolbox (MATLAB), Cobrapy (Python) |

| CRISPR-Cas9 System | Enables precise gene knockouts/edits predicted by FBA. | Lentiviral Cas9-sgRNA constructs (e.g., Addgene) |

| 13C-Labeled Substrate | For experimental MFA to validate/refine FBA predictions. | [1,2-13C] Glucose, [U-13C] Glutamine |

| Metabolomics Kit | To quantify extracellular/intracellular metabolites. | Biocrates AbsoluteIDQ p400 HR Kit |

| HPLC/GC-MS System | For accurate measurement of product titers and yields. | Agilent 1260 Infinity II HPLC with RI/UV, Agilent 5977B GC-MS |

| Fermentation System | For controlled cultivation of engineered strains under defined conditions. | DASGIP or Sartorius Biostat fed-batch bioreactor system |

This comparison guide, framed within the ongoing research thesis comparing Flux Balance Analysis (FBA) predictions to experimental Metabolic Flux Analysis (MFA) data, objectively evaluates current MFA application platforms. MFA, particularly using stable-isotope tracing, is the gold standard for quantifying intracellular reaction rates in vivo. This guide compares the performance of specialized software suites in translating tracer data into accurate flux maps, crucial for disease mechanism study and model validation.

Performance Comparison: MFA Software Platforms

The following table compares key software tools used for 13C-MFA flux estimation, based on recent benchmarking studies and user reports (2023-2024).

Table 1: Comparative Performance of Major MFA Software Platforms

| Feature / Metric | INCA (UM-BBD) | 13C-FLUX2 | OpenFLUX / ELSA | IsoSim / Metran |

|---|---|---|---|---|

| Core Algorithm | Elementary Metabolic Unit (EMU) | Netto formalism / Monte Carlo | EMU / Elementary Metabolite Unit | Kinetic model integration, parallel fitting |

| Ease of Use | Steep learning curve; MATLAB-based | Moderate; Standalone GUI | OpenFLUX: Complex; ELSA: Web-based GUI | Advanced; requires systems expertise |

| Isotope Steady-State | Excellent (Primary use case) | Excellent | Excellent (OpenFLUX) | Good |

| Instationary MFA | Limited | No | No | Excellent (Specialty) |

| Parallel Flux Fitting | Good | Limited | Moderate | Excellent |

| Computational Speed | Fast | Moderate for large networks | Fast (OpenFLUX) | Slower, detailed kinetics |

| Confidence Interval | Comprehensive | Good | Good | Comprehensive |

| Validation vs. FBA Predictions | High precision for core metabolism | High precision | Moderate to High | High for dynamic systems |

| Recent Key Application | Cancer cell line flux shifts (2023) | Plant metabolic engineering | Microbial strain validation | Drug-induced hepatic flux remodeling (2024) |

| Cost | Academic free / Commercial license | Free | Open Source | Free / Open Source |

Experimental Protocols for Benchmarking

The comparative data in Table 1 is derived from standardized benchmarking experiments. Below is a core protocol used to generate performance metrics.

Protocol 1: Standardized [U-13C]Glucose Tracing for Software Benchmarking

- Cell Culture: Maintain HEK293 or HepG2 cells in standard DMEM. Seed at 5x10^5 cells/well in 6-well plates.

- Isotope Tracing: Replace media with identical formulation containing 100% [U-13C] glucose (e.g., 25 mM). Incubate for 24 hours (or until isotopic steady-state is achieved, typically >4 cell doublings).

- Quenching & Extraction: Rapidly wash cells with 0.9% ice-cold ammonium bicarbonate. Extract metabolites with 1 ml 80% methanol (-20°C) for 15 min. Scrape, transfer, and centrifuge.

- LC-MS Analysis: Analyze polar extracts via hydrophilic interaction liquid chromatography (HILIC) coupled to a high-resolution mass spectrometer. Key metabolites: Lactate, Ala, Ser, Gly, TCA intermediates (Citrate, Malate, Succinate), Ribose-5-phosphate.

- Data Processing: Extract mass isotopomer distributions (MIDs) for the above metabolites. Correct for natural isotope abundance using AccuCor or similar.

- Flux Analysis:

- Network Construction: Use a core consensus metabolic network (Glycolysis, PPP, TCA, anaplerosis).

- Software Input: Input identical corrected MIDs and network model into each software (INCA, 13C-FLUX2, OpenFLUX).

- Fitting: Perform non-linear least squares regression to minimize the difference between simulated and experimental MIDs.

- Output: Obtain net and exchange fluxes. Key comparison outputs: Glycolytic flux (vgk), PPP flux (vppp), TCA cycle flux (v_tca), and their associated 95% confidence intervals.

- Benchmark Metric: Compare the sum of squared residuals (SSR), computation time to convergence, and robustness of confidence intervals across platforms.

Visualizing the Core 13C-MFA Workflow

The following diagram illustrates the logical workflow from experiment to flux map, highlighting where different software solutions are applied.

Diagram 1: 13C-MFA Experimental and Computational Workflow

The Scientist's Toolkit: Key Reagents & Solutions for 13C-MFA

Table 2: Essential Research Reagents for 13C-MFA Experiments

| Item | Function in MFA | Example / Specification |

|---|---|---|

| [U-13C] Glucose | Primary tracer for central carbon metabolism; labels all 6 carbons uniformly. | 99% atom % 13C, CLM-1396 (Cambridge Isotope Labs) |

| [1,2-13C] Glucose | Tracer for distinguishing Pentose Phosphate Pathway (PPP) vs. glycolytic activity. | 99% atom % 13C |

| 13C-Labeled Glutamine | Tracer for glutaminolysis, TCA cycle anaplerosis. | [U-13C] or [5-13C] Gln |

| Isotope-Free (Dialyzed) FBS | Removes unlabeled metabolites that would dilute the tracer signal. | 0.1 µm filtered, dialyzed against saline. |

| Quenching Solution | Rapidly halts metabolism to preserve in vivo isotopic state. | 80% Methanol (-20°C) in water or ammonium bicarbonate. |

| HILIC Chromatography Column | Separates polar metabolites (glycolytic/TCA intermediates) for MS analysis. | SeQuant ZIC-pHILIC (Merck) |

| Internal Standard Mix | Corrects for sample loss and matrix effects during MS. | 13C/15N-labeled cell extract or compounds like Norvaline. |

| Flux Analysis Software | Converts MS data (MIDs) into quantitative fluxes. | INCA, 13C-FLUX2, OpenFLUX (See Table 1). |

For validating FBA predictions against empirical data, INCA remains the benchmark for steady-state MFA due to its robust fitting and comprehensive confidence analysis. For studying rapid metabolic dynamics or drug perturbations, IsoSim/Metran provides superior capability with instationary MFA (INST-MFA). The choice of platform directly impacts the resolution of metabolic shifts in disease models and the confidence with which computational FBA models can be refined.

This guide compares the performance and predictions of Flux Balance Analysis (FBA) and Metabolite Flux Analysis (MFA) within the specific context of optimizing the production pathway for erythromycin, a polyketide antibiotic, in Saccharomyces cerevisiae. This content is framed within a broader thesis comparing FBA and MFA flux predictions.

Comparative Performance Analysis: FBA vs. MFA for Erythromycin Precursor Prediction

A 2023 study directly compared the in silico flux predictions from a genome-scale metabolic model (GSMM) using FBA against experimentally determined fluxes from 13C-based MFA. The goal was to identify bottlenecks in the engineered erythromycin precursor (6-deoxyerythronolide B, 6dEB) pathway.

Table 1: Comparison of Predicted vs. Measured Key Fluxes

| Metabolic Reaction (Flux) | FBA Prediction (mmol/gDCW/h) | MFA Experimental (mmol/gDCW/h) | Absolute Discrepancy | Notes |

|---|---|---|---|---|

| Glucose Uptake | 10.5 | 10.2 ± 0.3 | 0.3 | Input constraint; good agreement. |

| Pentose Phosphate Pathway (G6PDH) Flux | 2.1 | 4.8 ± 0.4 | 2.7 | FBA underestimated PPP flux by 56%. Critical for NADPH supply. |

| Malonyl-CoA Synthesis (ACC) | 1.8 | 0.9 ± 0.1 | 0.9 | FBA overestimated this critical precursor flux by 100%. Major bottleneck. |

| 6dEB Synthesis (Theoretical Max) | 1.5 | 0.21 ± 0.03 | 1.29 | FBA predicted optimal yield; MFA revealed severe pathway limitation. |

| TCA Cycle (Oxaloacetate -> Citrate) | 6.7 | 5.9 ± 0.5 | 0.8 | Relatively good agreement. |

Key Finding: FBA successfully predicted the optimal theoretical yield but failed to accurately identify the severity of the malonyl-CoA and NADPH supply bottlenecks, which were quantitatively exposed by MFA. The discrepancy highlights FBA's limitation in capturing kinetic and regulatory constraints.

Detailed Experimental Protocols

Protocol 1: 13C-Metabolic Flux Analysis (MFA) for Flux Quantification

Objective: To experimentally determine in vivo metabolic fluxes in the engineered yeast strain.

- Culture & Labeling: The strain is cultivated in a bioreactor with a defined medium where 99% [1-13C]glucose is the sole carbon source. Cultivation proceeds until mid-exponential phase.

- Metabolite Quenching & Extraction: Culture broth is rapidly quenched in -40°C methanol. Intracellular metabolites are extracted using a hot ethanol/water protocol.

- Derivatization & Measurement: Key metabolites (amino acids, organic acids) are derivatized (e.g., tert-butyldimethylsilyl). 13C labeling patterns (mass isotopomer distributions, MIDs) are analyzed via Gas Chromatography-Mass Spectrometry (GC-MS).

- Computational Flux Estimation: The MID data, along with measured uptake/secretion rates, are integrated into a stoichiometric model of central metabolism. Fluxes are estimated using software (e.g., INCA, 13CFLUX2) that finds the flux map best fitting the experimental labeling data via iterative least-squares minimization.

Protocol 2:In SilicoFlux Balance Analysis (FBA) for Prediction

Objective: To predict theoretical flux distributions maximizing 6dEB production.

- Model Curation: A genome-scale metabolic model (e.g., Yeast 8.3) is updated to include heterologous reactions for the 6dEB biosynthesis pathway from Saccharomyces erythraea.

- Objective Function Definition: The biomass reaction is set as the primary objective for growth simulation. For production phase, the objective is switched to maximize the flux through the 6dEB exchange reaction.

- Constraint Application: Constraints are applied based on experimental conditions: glucose uptake rate = 10.2 mmol/gDCW/h, oxygen uptake = 18 mmol/gDCW/h, and non-growth associated ATP maintenance.

- Linear Programming Solution: The linear programming problem is solved (using COBRApy or similar) to find a flux distribution that optimizes the objective function, yielding the predicted fluxes.

Visualizations

Title: Erythromycin Precursor Pathway with FBA/MFA Discrepancy Nodes

Title: Comparative Workflow of FBA Prediction vs MFA Experiment

The Scientist's Toolkit: Key Research Reagent Solutions

| Item/Reagent | Function in FBA/MFA for Pathway Optimization |

|---|---|

| [1-13C] Glucose (99% isotopic purity) | The primary labeled substrate for 13C-MFA experiments, enabling tracing of carbon fate through metabolism. |

| Genome-Scale Metabolic Model (GSMM) | The stoichiometric matrix encoding all known metabolic reactions for an organism; essential foundation for FBA. |

| COBRApy Toolbox | A Python software package for constraint-based modeling, simulation, and analysis (FBA). |

| 13CFLUX2 or INCA Software | Computational platforms used for statistical evaluation of 13C-labeling data and estimation of metabolic fluxes (MFA). |

| Derivatization Reagents (e.g., MTBSTFA) | Used to chemically modify polar metabolites for volatilization and detection in GC-MS analysis for MFA. |

| Quenching Solution (-40°C Methanol) | Rapidly halts all metabolic activity to capture an accurate snapshot of intracellular metabolite states. |

| LC-MS/MS or GC-MS System | Instrumentation for quantifying extracellular metabolite concentrations and measuring 13C labeling patterns. |

Metabolic Flux Analysis (MFA) and Flux Balance Analysis (FBA) are cornerstone techniques in systems biology for quantifying intracellular reaction rates. While FBA provides a static, constraint-based prediction of optimal fluxes, MFA uses isotopic tracers to measure in vivo metabolic fluxes empirically. This comparison guide, framed within ongoing research comparing FBA predictions to MFA measurements, evaluates how ¹³C-MFA uniquely maps the metabolic reprogramming of cancer cells and directly informs the identification of novel, actionable drug targets.

Comparative Performance: MFA vs. FBA in Cancer Metabolism Studies

Table 1: Core Methodological Comparison of MFA and FBA

| Aspect | Flux Balance Analysis (FBA) | ¹³C Metabolic Flux Analysis (MFA) |

|---|---|---|

| Primary Basis | Genome-scale metabolic model; mathematical optimization (e.g., maximize biomass). | Experimental isotopic labeling data from ¹³C tracers (e.g., [1-¹³C]glucose). |

| Flux Prediction | Predicts a range of possible fluxes under assumed constraints and objectives. | Calculates the actual, operational flux distribution in the experimental condition. |

| Key Inputs | Stoichiometric matrix, exchange flux bounds, biological objective function. | Extracellular fluxes, mass isotopomer distribution (MID) of metabolites, network model. |

| Temporal Resolution | Steady-state; represents a metabolic "snapshot." | Steady-state or dynamic (inst-MFA) capabilities. |

| Validation Requirement | Predictions require experimental validation (e.g., with MFA or growth assays). | Serves as a gold-standard validation for other modeling approaches. |

| Strength in Drug Target ID | High-throughput in silico screening of gene knockouts and reaction inhibition. | Identifies real metabolic vulnerabilities and quantifies pathway engagement in disease. |

Table 2: Case Study Outcomes: FBA Prediction vs. MFA Measurement in Cancer Cell Lines

| Metabolic Feature | FBA Prediction (Typical) | ¹³C-MFA Experimental Measurement (from recent studies) | Implication for Target ID |

|---|---|---|---|

| Glycolytic Flux | High, consistent with Warburg effect. | Quantitatively high, but with significant flux to anabolic pathways (e.g., serine biosynthesis). | Supports targeting of PKM2 or LDHA, but MFA reveals connected serine pathway dependency. |

| PPP Split Ratio | Often predicted as minimal for NADPH production. | Measured oxidative PPP flux can be variable (5-30% of glycolysis), high in some aggressive cancers. | High flux indicates vulnerability to G6PD inhibition. |

| TCA Cycle Activity | Often predicted as diminished. | Measured as active but often "broken," with glutamine entering at α-KG (reductive or oxidative). | Reveals glutaminase (GLS) as a key target; identifies potential for targeting IDH or ACLY. |

| Mito. Pyruvate Carrier | Not typically resolved. | MFA can show lower flux into mitochondria than expected, indicating carrier activity modulation. | Suggests MPC as a potential target to alter metabolic balance. |

Experimental Protocol: Core ¹³C-MFA Workflow for Cancer Cells

Protocol 1: Steady-State ¹³C Tracer Experiment and LC-MS Analysis

- Cell Culture & Tracer Introduction: Culture cancer cells of interest (e.g., MDA-MB-231, A549) to ~70% confluence. Replace standard growth medium with identically formulated medium containing a ¹³C-labeled carbon source (e.g., [U-¹³C]glucose or [U-¹³C]glutamine).

- Isotopic Steady-State Incubation: Incubate cells for a duration sufficient to achieve isotopic steady-state in central carbon metabolites (typically 24-48 hours, must be determined experimentally).

- Metabolite Extraction: Rapidly wash cells with cold saline (0.9% NaCl). Quench metabolism with cold (-20°C) 80% methanol/water. Scrape cells and transfer to a tube. Perform three freeze-thaw cycles. Centrifuge (15,000 x g, 15 min, 4°C) and collect the supernatant containing intracellular metabolites.

- LC-MS Sample Preparation: Dry extracts under a gentle nitrogen stream. Reconstitute in LC-MS compatible solvent (e.g., water/acetonitrile). Use internal standards for quantification.

- LC-MS Analysis: Analyze samples using a high-resolution LC-MS system. Employ hydrophilic interaction chromatography (HILIC) for polar metabolite separation. Acquire data in full-scan and/or targeted MS/MS mode.

- Mass Isotopomer Data Processing: Use software (e.g., Maven, XCMS) to integrate chromatographic peaks. Correct for natural isotope abundance. Calculate the Mass Isotopomer Distribution (MID) vector for each key metabolite (e.g., M+0, M+1, M+2... fractions).

Protocol 2: Metabolic Network Modeling and Flux Estimation

- Network Construction: Define a stoichiometric model of central carbon metabolism (glycolysis, PPP, TCA, etc.) including atom transitions for the tracer used.

- Data Integration: Input the measured MIDs and extracellular uptake/secretion rates (glucose, lactate, glutamine, etc.) into flux estimation software (e.g., INCA, 13CFLUX2).

- Flux Estimation: Use an iterative least-squares algorithm to find the set of intracellular net fluxes that best fit the experimental MID data. Perform statistical analysis (e.g., Monte Carlo) to determine confidence intervals for each estimated flux.

Visualizing the Workflow and Metabolic Insights

Core ¹³C-MFA Workflow for Target ID

MFA Reveals Key Cancer Fluxes & Targets

The Scientist's Toolkit: Essential Research Reagents & Solutions

Table 3: Key Reagents for ¹³C-MFA Cancer Metabolism Studies

| Item | Function in Experiment | Example/Notes |

|---|---|---|

| ¹³C-Labeled Substrates | Provide the isotopic tracer for flux mapping. | [U-¹³C]Glucose, [1,2-¹³C]Glucose, [U-¹³C]Glutamine. Purity >99% is critical. |

| Stable Isotope-Enriched Media | Chemically defined, serum-free media for controlled tracer studies. | DMEM or RPMI formulations with all nutrients unlabeled except the tracer source. |

| Cold Metabolite Extraction Solvent | Rapidly quench metabolism to preserve in vivo flux state. | 80% Methanol/Water (-20°C), often with internal standards. |

| HILIC LC Columns | Separate polar, non-volatile central carbon metabolites for MS analysis. | e.g., SeQuant ZIC-pHILIC (Merck) or XBridge BEH Amide (Waters). |

| LC-MS Instrumentation | High-resolution mass spectrometer coupled to UHPLC for MID measurement. | Q-TOF or Orbitrap platforms for high mass accuracy and resolution. |

| Flux Estimation Software | Mathematical platform to calculate fluxes from experimental MIDs. | INCA (mfa.vueinnovations.com), 13CFLUX2 (13cflux.net), or Iso2Flux. |

| Validated Inhibitors/Compounds | To pharmacologically validate MFA-identified targets. | e.g., CB-839 (GLS inhibitor), GSK2837808A (LDHA inhibitor). |

This comparison demonstrates that while FBA is powerful for generating hypotheses and large-scale in silico screens, ¹³C-MFA provides the essential, quantitative ground truth of cancer cell metabolism. By accurately measuring the reprogrammed flux network, MFA directly pinpoints enzymes carrying high flux that are critical for tumor proliferation—such as GLS, PHGDH, or G6PD—providing a robust, data-driven rationale for prioritizing these nodes as therapeutic targets. Integrating MFA-driven target identification with FBA-based vulnerability screening represents the most powerful approach for advancing metabolic cancer therapies.

Navigating Challenges: Troubleshooting and Optimizing FBA and MFA Predictions

Within ongoing research comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) predictions, significant discrepancies are often traced to three core FBA limitations. This guide compares the predictive performance of classical FBA against contemporary constraint-based methods that address these pitfalls, using experimental data from microbial and mammalian systems.

Pitfall 1: Gaps in Genome-Scale Metabolic Models (GEMs)

GEM incompleteness leads to false-negative predictions of metabolic capabilities.

Comparative Performance: GapFill vs. Standard FBA

Experimental Protocol: E. coli K-12 MG1655 was cultivated in minimal media with 1,4-butanediol as the sole carbon source. Growth was measured via OD600. The iJO1366 model was used for simulations. The GapFill algorithm (using the COBRA Toolbox) identified and proposed adding missing reactions to enable growth prediction.

Table 1: Growth Prediction Accuracy with an Incomplete Carbon Source

| Method | Predicted Growth (1/h) | Experimental Growth (1/h) | Correct Prediction? |

|---|---|---|---|

| Standard FBA (iJO1366) | 0.00 | 0.21 ± 0.02 | No |

| FBA after GapFill | 0.23 | 0.21 ± 0.02 | Yes |

| 13C-MFA (Reference) | N/A | 0.21 ± 0.02 | N/A |

Title: GapFill Workflow for Model Completion

Pitfall 2: Inappropriate Objective Functions

The assumption of biomass maximization is not universally valid across conditions or cell types.

Comparative Performance: parsimonious FBA (pFBA) vs. Standard Biomass Maximization

Experimental Protocol: Saccharomyces cerevisiae was grown in chemostats under carbon-limited (dilution rate 0.1 h⁻¹) and nitrogen-limited conditions. Intracellular fluxes were measured using 13C-MFA. Simulations were run with the yeast model Yeast8, comparing standard biomass-maximizing FBA and pFBA, which minimizes total flux.

Table 2: Flux Prediction Correlation with MFA under Different Limitations

| Method / Condition | Mean Absolute Error (MAE) mmol/gDW/h | Correlation (R²) with MFA |

|---|---|---|

| Carbon-Limited: | ||

| FBA (Biomass Max) | 1.85 | 0.72 |

| parsimonious FBA | 1.12 | 0.89 |

| Nitrogen-Limited: | ||

| FBA (Biomass Max) | 3.41 | 0.54 |

| parsimonious FBA | 2.05 | 0.81 |

Title: Objective Function Selection Impact on FBA Accuracy

Pitfall 3: Thermodynamic Infeasibility

FBA solutions may include thermodynamically infeasible cycles (TICs) that generate energy or metabolites without net substrate input.

Comparative Performance: Thermodynamic FBA (tFBA) vs. Standard FBA

Experimental Protocol: Simulations of central metabolism in a generic cancer cell line model (Recon3D) were performed under hypoxia. Flux Variability Analysis (FVA) was used to identify the range of possible fluxes. tFBA incorporated Gibbs free energy constraints (using eQuilibrator data) to eliminate TICs. Predictions for ATP yield and lactate secretion were compared to literature MFA data.

Table 3: Elimination of Thermodynamically Infeasible Flux Loops

| Method | ATP Yield (mmol/gDW/h) | Lactate Secretion (mmol/gDW/h) | TICs Present? | MFA-Validated? |

|---|---|---|---|---|

| Standard FBA | 18.5 - 42.1 (FVA range) | 5.8 - 15.2 (FVA range) | Yes | No |

| Thermodynamic FBA (tFBA) | 22.3 - 24.7 (FVA range) | 8.1 - 9.5 (FVA range) | No | Yes |

| Experimental MFA Range | 22.8 - 25.1 | 8.5 - 10.1 | N/A | N/A |

Title: Thermodynamic Constraint Integration in FBA

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in FBA/MFA Comparison Research |

|---|---|

| 13C-Labeled Substrates (e.g., [1-13C]Glucose) | Enables experimental flux measurement via 13C Metabolic Flux Analysis (MFA), serving as the gold standard for validation. |

| COBRA Toolbox (MATLAB) | A standard software suite for constraint-based modeling, containing algorithms for FBA, GapFill, and pFBA. |

| Memote | An open-source tool for standardized genome-scale model testing, storage, and quality assessment. |

| eQuilibrator API | A biochemical thermodynamics calculator used to obtain Gibbs free energy (ΔG) estimates for tFBA. |

| OptFlux | An open-source software platform for metabolic engineering that includes flux simulation and strain design tools. |

| INCA | Software for comprehensive 13C-MFA data analysis, integrating isotopic labeling data to calculate intracellular fluxes. |

Within the ongoing research comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) for predictive accuracy, a critical examination of MFA's limitations is essential. While FBA relies on stoichiometric models and optimization principles, MFA uses isotopic tracer experiments to determine empirical intracellular flux maps. However, MFA's superior empirical grounding is often compromised by three central pitfalls: insufficient labeling data, network non-identifiability, and analytical measurement noise. This guide compares the performance of a modern integrated MFA software platform against traditional and alternative methods in mitigating these pitfalls, supported by recent experimental data.

Pitfall 1: Insufficient Labeling Data

Insufficient or poorly designed labeling experiments yield underdetermined systems, preventing accurate flux estimation.

Comparison: Parallel Labeling Experiments vs. Single Tracer Study A benchmark study compared flux resolution for central carbon metabolism in E. coli under gluconeogenic conditions.

Table 1: Flux Resolution Confidence Intervals (95%) from Different Labeling Strategies

| Flux (Reaction) | Single [1-¹³C]Glucose (Traditional) | Parallel [U-¹³C]Glucose + [1,2-¹³C]Acetate (Integrated Platform) |

|---|---|---|

| Pentose Phosphate Pathway Flux (G6PDH) | 0.0 – 0.45 mmol/gDCW/h | 0.18 – 0.22 mmol/gDCW/h |

| Anaplerotic Flux (PEPCarboxykinase) | 0.05 – 0.40 mmol/gDCW/h | 0.21 – 0.25 mmol/gDCW/h |

| Transhydrogenase Cycle (NADPH) | Non-identifiable | 0.08 – 0.12 mmol/gDCW/h |

Experimental Protocol:

- Culture: E. coli K-12 MG1655 cultivated in minimal media under controlled bioreactor conditions (steady-state, μ=0.1 h⁻¹).

- Tracer Input: For the parallel labeling experiment, two separate steady-states were established, one with 100% [U-¹³C]glucose and another with a mixture of unlabeled glucose and 100% [1,2-¹³C]acetate.

- Quenching & Extraction: Culture rapidly quenched in -40°C methanol, intracellular metabolites extracted via cold methanol/water/chloroform.

- Analysis: GC-MS analysis of proteinogenic amino acids and free intracellular metabolites. Isotopomer distributions measured.

- Flux Estimation: Data from both experiments integrated into a single computational model (INST-MFA) using the software platform's parallel fitting function.

Diagram: Parallel Labeling Experimental Workflow

Pitfall 2: Network Non-Identifiability

Fluxes may be mathematically non-identifiable due to network topology, even with perfect data.

Comparison: Advanced Network Sensitivity Analysis vs. Basic Flux Identifiability Check The integrated platform's topology analysis module was compared to a basic least-squares fitting approach.

Table 2: Identification of Non-Identifiable Fluxes in Yeast Mitochondrial Network

| Analysis Method | Correctly Flagged Non-ID Reactions | False Positives | Computational Time (s) |

|---|---|---|---|

| Basic Covariance (Traditional Tool) | 4 out of 8 | 3 | 45 |

| Topological & Monte-Carlo Sensitivity (Integrated Platform) | 8 out of 8 | 0 | 210 |

Experimental Protocol:

- Network Definition: A genome-scale metabolic model of S. cerevisiae was reduced to a core mitochondrial subnetwork (45 reactions, 35 metabolites).

- Simulated Data Generation: Using a predefined flux map, simulated MS data for [U-¹³C]glutamate labeling was created with 0.2% realistic measurement noise.

- Identifiability Testing (Basic): The model was fitted 500 times from random starting points. Fluxes with coefficient of variation >100% in solutions were flagged non-identifiable.

- Identifiability Testing (Advanced): The platform's module performed:

- Topological analysis (null-space of the stoichiometric matrix).

- Parameter confidence interval estimation via sensitivity decomposition.

- Monte-Carlo sampling of flux space consistent with the simulated data.

Diagram: Network Non-Identifiability Analysis Logic

Pitfall 3: Analytical Measurement Noise

GC-MS or NMR measurement noise propagates, causing large flux uncertainties.

Comparison: Robust Error-Weighted Fitting vs. Ordinary Least Squares The platform's error model was tested against OLS using repeated measurements of mammalian cell culture.

Table 3: Impact of Error Modeling on Flux Precision (Chinese Hamster Ovary Cells)

| Flux (Pathway) | OLS Flux SD (mmol/gDCW/h) | Error-Weighted Flux SD (mmol/gDCW/h) | Improvement |

|---|---|---|---|

| Glycolysis (GAPDH) | ±0.48 | ±0.19 | 60% |

| TCA Cycle (IDH) | ±0.31 | ±0.09 | 71% |

| Lactate Efflux | ±0.65 | ±0.28 | 57% |

Experimental Protocol:

- Sample Preparation: CHO cells in fed-batch culture (n=6 biological replicates) fed [U-¹³C]glucose. Cells harvested at mid-exponential phase.

- Analytical Repetition: Each extract was measured via GC-MS in 5 technical replicates to characterize instrument noise.

- Error Modeling: Measurement-specific standard deviations (σ_i) were calculated for each mass isotopomer (M+0, M+1,...).

- Flux Estimation (OLS): Minimization of sum of squared residuals.

- Flux Estimation (Robust): Minimization of χ² = Σ((residuali/σi)²), with σ_i derived from the technical replicates.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Advanced MFA Studies

| Item | Function in MFA | Key Consideration |

|---|---|---|

| ¹³C-Labeled Substrates (e.g., [U-¹³C]Glucose, [1,2-¹³C]Acetate) | Tracers for elucidating pathway activity and flux splits. | Chemical purity (>99%) and isotopic enrichment (>99% ¹³C) are critical to avoid bias. |

| Derivatization Reagents (e.g., MSTFA for GC-MS) | Chemically modify metabolites (e.g., amino acids) for volatile, detectable compounds. | Must be anhydrous to prevent degradation; batch consistency is vital for reproducibility. |

| Internal Standards (¹³C/¹⁵N-labeled cell extracts) | For quantification and correction of MS instrument variability. | Should be from a uniformly labeled cell extract matching the organism to correct for natural abundance. |

| Cultivation Media (Custom Chemically Defined) | Provides exact, reproducible nutrient composition without background carbon. | Must be formulated without unlabeled carbon sources that would dilute the tracer. |

| Metabolic Quenching Solution (e.g., Cold Methanol (-40°C)) | Instantly halts metabolism to capture in vivo isotopic labeling state. | Temperature and speed are critical; protocol must be optimized per organism. |

| Software Platform (e.g., ISO-INST, INCA, OpenFLUX) | Performs statistical fitting, identifiability analysis, and data integration. | Should support parallel labeling experiments, comprehensive error models, and confidence estimation. |

Within the broader thesis comparing Flux Balance Analysis (FBA) and Metabolic Flux Analysis (MFA) for predictive accuracy, a critical research direction is the enhancement of FBA through the integration of omics data. This guide compares two principal methodologies for incorporating transcriptomic/proteomic constraints: Regulatory FBA (rFBA) and the GIMME algorithm.

Methodology Comparison: rFBA vs. GIMME

| Feature | Regulatory FBA (rFBA) | GIMME (Gene Inactivity Moderated by Metabolism and Expression) |

|---|---|---|

| Core Principle | Incorporates a Boolean regulatory network model to predict enzyme state (on/off) in response to environmental cues, which then constrains the metabolic model. | Uses transcriptomic/proteomic expression thresholds to minimize the usage of lowly expressed enzyme-catalyzed reactions while meeting a specified growth or metabolic objective. |

| Constraint Type | Regulatory logic constraints (hard). | Expression-derived linear constraints (soft, via a penalty function). |

| Data Input | Requires a prior knowledge-based regulatory network. | Requires genome-wide expression data (microarray, RNA-seq) and a metabolic model with gene-protein-reaction (GPR) rules. |