FBA vs 13C-MFA: A Critical Guide to Metabolic Flux Analysis for Systems Biology and Pharmaceutical Research

This article provides a comprehensive comparison of Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA), two cornerstone techniques for predicting metabolic flux.

FBA vs 13C-MFA: A Critical Guide to Metabolic Flux Analysis for Systems Biology and Pharmaceutical Research

Abstract

This article provides a comprehensive comparison of Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA), two cornerstone techniques for predicting metabolic flux. Tailored for systems biologists and drug development scientists, we dissect the theoretical foundations, practical methodologies, and specific applications of each approach. We detail how to troubleshoot common computational and experimental pitfalls, offer strategies for optimizing each method, and critically evaluate their validation frameworks and comparative performance. This guide synthesizes current best practices to empower researchers in selecting and applying the optimal flux prediction tool for biomedical discovery, from target identification to bioprocess optimization.

Core Principles Decoded: Understanding FBA and 13C-MFA from First Principles for Systems Biology

Flux analysis is the quantitative measurement of metabolic reaction rates, providing a dynamic picture of cellular physiology. Two dominant computational methods are Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA). This guide compares their performance in predicting metabolic fluxes, a critical capability for understanding disease mechanisms and engineering industrial microbes.

Core Methodology Comparison

| Feature | Flux Balance Analysis (FBA) | 13C-Metabolic Flux Analysis (13C-MFA) |

|---|---|---|

| Core Principle | Constraint-based optimization; assumes metabolic steady-state and optimality (e.g., growth maximization). | Isotopic tracing; uses 13C-labeling patterns in metabolites to infer intracellular fluxes. |

| Data Input | Genome-scale metabolic model (stoichiometry), growth/uptake/secretion rates. | 13C-labeling data (e.g., from GC-MS), extracellular fluxes, metabolic network model. |

| Flux Resolution | Net fluxes through pathways. Often predicts a range of possible fluxes (solution space). | Absolute, quantitative fluxes through central carbon metabolism, including bidirectional reactions. |

| Temporal Scope | Steady-state prediction. | Experimental steady-state or isotopically non-stationary. |

| Key Strength | Genome-scale capability; hypothesis generation; predicts optimal phenotypes. | High accuracy and resolution in core metabolism; validates model predictions. |

| Key Limitation | Relies on optimality assumption; limited kinetic/regulatory insight. | Experimentally intensive; typically restricted to central metabolism. |

Performance Comparison: Prediction vs. Experimental Validation

The following table summarizes data from comparative studies where FBA predictions were tested against 13C-MFA-determined experimental fluxes, considered the "gold standard" for validation.

| Organism / Condition | FBA Prediction Error (Relative to 13C-MFA) | 13C-MFA Experimental Error | Key Insight from Comparison | Source |

|---|---|---|---|---|

| E. coli (Aerobic, Glucose) | Up to 40% error in TCA cycle & glyoxylate shunt fluxes. | Typically <5-10% for major net fluxes. | FBA with growth maximization fails to predict efficient but suboptimal use of glyoxylate shunt. | [1] |

| S. cerevisiae (Crabtree Effect) | Mis-predicts respiro-fermentative transition point. | Quantifies precise split between respiration and fermentation. | Highlights need for regulatory constraints in FBA to capture metabolic switches. | [2] |

| CHO Cell Bioproduction | Overpredicts growth yield; underpredicts lactate secretion. | Accurately quantifies wasteful lactate metabolism. | 13C-MFA data can refine FBA models for mammalian cell culture optimization. | [3] |

| B. subtilis (Industrial Strain) | Correctly predicts high TCA flux trend but not absolute magnitude. | Provides precise absolute flux values for yield calculation. | FBA good for directional insights; 13C-MFA essential for quantitative process metrics. | [4] |

Experimental Protocols for Key Comparisons

1. Protocol for 13C-MFA Flux Determination (Validation Benchmark):

- Cell Cultivation: Grow cells in a controlled bioreactor with a defined medium where 20-100% of the primary carbon source (e.g., glucose) is replaced with its [1-13C] or [U-13C] isotopologue.

- Steady-State Harvest: Maintain cells at exponential growth for >5 generations to achieve isotopic steady state. Quench metabolism rapidly (e.g., in -40°C methanol).

- Metabolite Extraction & Derivatization: Extract intracellular metabolites. Derivatize amino acids (from protein hydrolysis) or central metabolites for analysis via Gas Chromatography-Mass Spectrometry (GC-MS).

- Mass Spectrometry: Measure mass isotopomer distributions (MIDs) of key fragments.

- Computational Flux Estimation: Use software (e.g., INCA, 13C-FLUX2) to fit a metabolic network model to the experimental MIDs and extracellular flux data via iterative least-squares regression, obtaining the most statistically likely flux map.

2. Protocol for FBA Prediction & Discrepancy Analysis:

- Model Curation: Obtain/construct a genome-scale metabolic reconstruction for the organism (e.g., from BIGG Models).

- Constraint Definition: Apply measured substrate uptake rates, growth rate, and byproduct secretion rates as constraints to the model solution space.

- Objective Function: Typically, biomass maximization is set as the objective for microbial growth simulations.

- Flux Prediction: Solve the linear programming problem to obtain a flux distribution (using COBRApy or similar).

- Comparison: Map the predicted fluxes from central metabolism onto the corresponding fluxes from the 13C-MFA study and calculate percent differences.

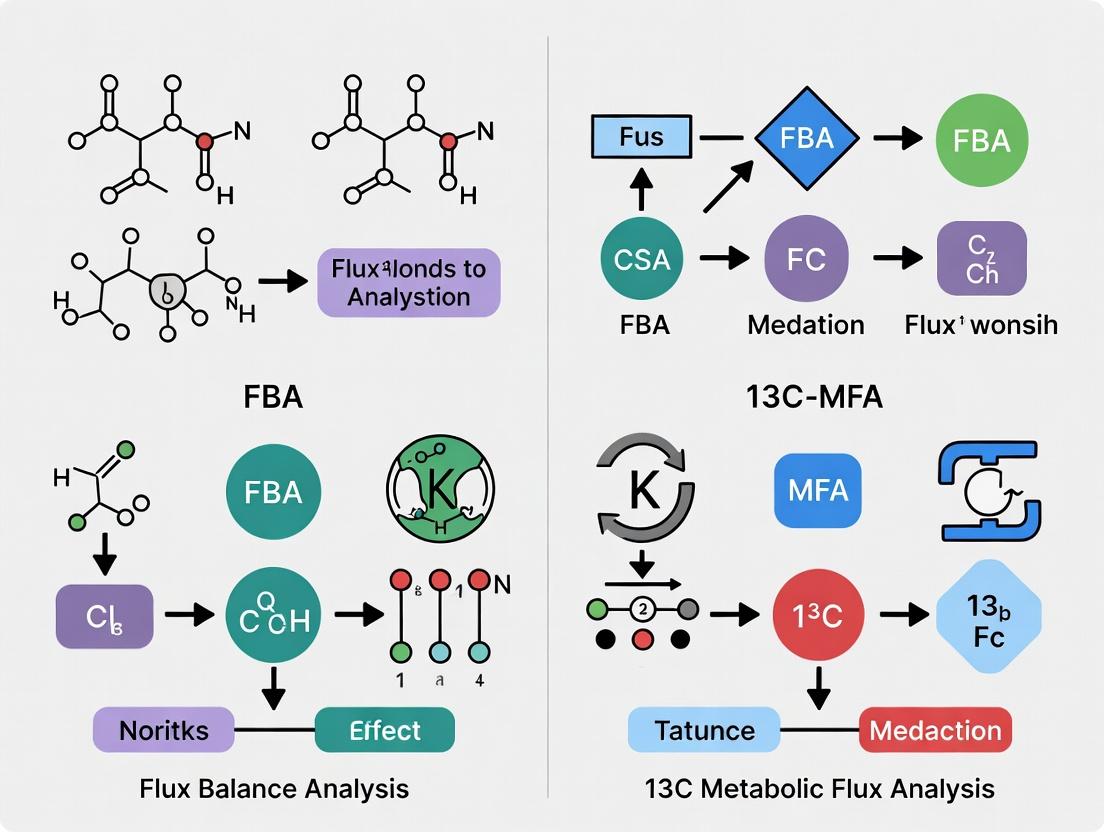

Visualization of the Flux Analysis Workflow & Integration

Title: Complementary Paths to a Metabolic Flux Map

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Kit | Function in Flux Analysis |

|---|---|

| U-13C-Glucose (or other 13C-substrates) | The essential tracer for 13C-MFA; introduces measurable isotopic label into metabolism. |

| Quenching Solution (e.g., -40°C Methanol/Buffer) | Rapidly halts cellular metabolism to capture an accurate metabolic snapshot. |

| GC-MS System with Autosampler | Workhorse instrument for measuring mass isotopomer distributions in derivatized samples. |

| Derivatization Reagents (e.g., MSTFA, MBTSTFA) | Chemically modify polar metabolites (amino acids, organic acids) for volatile GC-MS analysis. |

| COBRA Toolbox (MATLAB) / COBRApy (Python) | Standard software suites for constructing, constraining, and solving FBA problems. |

| 13C-MFA Software (INCA, 13C-FLUX2) | Specialized platforms for statistical fitting of flux models to 13C-labeling data. |

| Defined Cell Culture Media Kits | Essential for precise control of nutrient inputs, especially for isotopic tracer studies. |

| Metabolite Standard Kits (e.g., for GC-MS) | Contains unlabeled and labeled standards for instrument calibration and quantification. |

Within the ongoing research thesis comparing Flux Balance Analysis (FBA) to 13C-Metabolic Flux Analysis (13C-MFA) for flux prediction, this guide provides a comparative examination of constraint-based modeling approaches. FBA is a computational method for predicting metabolic flux distributions in stoichiometric networks under steady-state assumptions, widely used for its genome-scale capabilities and minimal data requirements.

Core Methodology Comparison: FBA vs. 13C-MFA

Table 1: Fundamental Comparison of Flux Prediction Methodologies

| Feature | Flux Balance Analysis (FBA) | 13C-Metabolic Flux Analysis (13C-MFA) |

|---|---|---|

| Core Principle | Mathematical optimization of an objective function (e.g., biomass) subject to stoichiometric and capacity constraints. | Statistical fitting of intracellular fluxes to measured 13C isotopic labeling patterns in metabolites. |

| Data Requirements | Genome-scale metabolic reconstruction, exchange flux measurements (optional), objective function. | Network model (core metabolism), measured extracellular fluxes, Mass Isotopomer Distribution (MID) data from GC-MS/LC-MS. |

| System Scale | Genome-scale (1000s of reactions). | Medium-scale (50-200 reactions, central carbon metabolism). |

| Key Assumption | Steady-state, mass balance, optimization of cellular objective. | Isotopic steady-state, metabolic steady-state, reaction network stoichiometry. |

| Output | A single flux distribution maximizing/minimizing the objective. | A range of statistically feasible flux distributions with confidence intervals. |

| Temporal Resolution | Pseudo-steady-state snapshot. | Pseudo-steady-state snapshot. |

| Primary Use Case | Hypothesis generation, gap-filling, predicting knockout effects, strain design. | Quantitative, rigorous flux elucidation in central metabolism for physiological studies. |

Performance Comparison: Predictive Accuracy and Utility

Table 2: Experimental Performance Comparison from Recent Studies

| Study & Organism | FBA Prediction Error* | 13C-MFA Resolution* | Key Finding | Experimental Context |

|---|---|---|---|---|

| E. coli under varying carbon sources [1] | 15-40% for central carbon fluxes | 5-10% confidence intervals | FBA predictions highly sensitive to defined objective function; 13C-MFA provided ground truth. | Compared FBA predictions (max growth objective) to 13C-MFA fluxes from chemostat cultures. |

| S. cerevisiae gene knockouts [2] | Successful qualitative prediction in ~70% of cases. | Quantitative flux rewiring measured. | FBA effective for predicting growth/no-growth; 13C-MFA essential for quantifying metabolic bypasses. | Compared FBA-predicted essential genes and flux rerouting to 13C-MFA data from knockout strains. |

| Cancer cell lines [3] | Correlated poorly (>50% error) with measured exometabolomics. | High consistency with extracellular uptake/secretion data. | Tissue-specific model constraints improved FBA accuracy but 13C-MFA remained reference. | Integrated transcriptomics to constrain FBA models; validated with parallel 13C-MFA experiments. |

| B. subtilis production strain [4] | Correctly predicted optimal substrate but overestimated yield by 25%. | Precisely identified futile cycles limiting yield. | 13C-MFA identified thermodynamic constraints missed by standard FBA. | Used 13C-MFA to refine FBA model constraints, improving design of production strains. |

*Error metrics are approximate and study-dependent, representing root-mean-square error or relative difference for key fluxes.

Detailed Experimental Protocols

Protocol 1: Standard Flux Balance Analysis Workflow

- Model Reconstruction: Acquire a genome-scale metabolic network (e.g., from BIGG Models) for the target organism.

- Define Constraints: Apply constraints based on experimental conditions:

- Set exchange reaction bounds for available nutrients (e.g., glucose uptake = -10 mmol/gDW/h).

- Apply thermodynamic constraints (irreversible reactions) and capacity constraints (Vmax) if available.

- Define Objective: Select an objective function, typically biomass reaction maximization for growth studies.

- Solve Linear Programming Problem: Use a solver (e.g., COBRApy, MATLAB's

linprog) to find the flux distribution (v) that:- Maximizes Z = cᵀv (objective)

- Subject to: S·v = 0 (mass balance)

- And: lb ≤ v ≤ ub (capacity constraints)

- Analyze Solution: Extract flux values, particularly through key pathways of interest.

Protocol 2: Parallel 13C-MFA Validation Experiment

- Culture & Tracer Experiment: Grow cells in a controlled bioreactor with a defined 13C-labeled substrate (e.g., [1,2-13C]glucose). Ensure metabolic and isotopic steady-state.

- Sampling & Quenching: Rapidly sample culture and quench metabolism (e.g., in -40°C methanol).

- Metabolite Extraction & Derivatization: Extract intracellular metabolites. Derivatize for GC-MS analysis (e.g., TBDMS for amino acids).

- Mass Spectrometry: Measure Mass Isotopomer Distributions (MIDs) of proteinogenic amino acids or pathway intermediates.

- Flux Estimation: Use software (INCA, 13CFLUX2) to fit the metabolic network model to the measured MIDs and extracellular fluxes via iterative least-squares minimization, generating flux maps with confidence intervals.

Visualization of Workflows and Relationships

Title: FBA Iterative Workflow Diagram

Title: FBA vs 13C-MFA Conceptual Comparison

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for Comparative Flux Studies

| Item | Function in FBA/13C-MFA Research | Example Product/Kit |

|---|---|---|

| 13C-Labeled Substrates | Essential for 13C-MFA tracer experiments to generate isotopic labeling patterns. | [1-13C]Glucose, [U-13C]Glucose (Cambridge Isotope Laboratories) |

| Quenching Solution | Rapidly halts metabolism to capture accurate intracellular metabolite snapshots. | Cold (-40°C) 60% Methanol/Buffered Saline |

| Derivatization Reagents | Prepare metabolites for detection by GC-MS (e.g., trimethylsilylation). | N-methyl-N-(tert-butyldimethylsilyl)trifluoroacetamide (MTBSTFA) |

| Metabolite Standards (Isotopic) | Quantify absolute concentrations and correct for natural isotope abundance in MS data. | 13C-labeled Amino Acid Mix (e.g., Spectra Stable Isotope Kit) |

| Cell Culture Media (Chemically Defined) | Enables precise control of nutrient availability and labeling for both FBA constraints and MFA. | Custom formulations without unlabeled carbon interference. |

| Metabolic Network Model | The computational stoichiometric framework for both FBA and 13C-MFA. | AGORA (microbes), Recon (human) from public databases, or custom models. |

| Software Suite | Perform FBA optimization and 13C-MFA flux fitting. | COBRA Toolbox (MATLAB/Python) for FBA; INCA or 13CFLUX2 for 13C-MFA. |

FBA offers unparalleled scalability and utility for in silico hypothesis generation and strain design in metabolic engineering. However, as part of a comprehensive thesis on flux prediction, experimental data consistently shows that 13C-MFA remains the gold standard for quantitative, accurate flux determination in core metabolism. The integration of 13C-MFA data to constrain and validate genome-scale FBA models represents a powerful synergistic approach, enhancing the predictive power of constraint-based modeling for both basic research and industrial drug/bioprocess development.

Thesis Context: FBA vs. 13C-MFA in Flux Prediction

A core thesis in metabolic engineering compares Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA) for predicting intracellular reaction rates (fluxes). FBA is a constraint-based modeling approach that predicts fluxes by optimizing an objective function (e.g., biomass yield) using stoichiometric models and uptake/secretion rates. It provides a theoretical flux map but lacks experimental validation of intracellular fluxes. In contrast, 13C-MFA is an experimental approach that uses stable isotope tracers, mass spectrometry, and computational modeling to determine absolute, in vivo metabolic fluxes. This guide compares their performance, protocols, and applications.

Performance Comparison: FBA vs. 13C-MFA

The table below summarizes a comparative analysis of the two methods based on recent studies.

Table 1: Comparative Analysis of FBA and 13C-MFA for Flux Prediction

| Feature | Flux Balance Analysis (FBA) | 13C-Metabolic Flux Analysis (13C-MFA) |

|---|---|---|

| Core Principle | Mathematical optimization using stoichiometry & constraints. | Fitting of isotopic labeling data to a kinetic model. |

| Required Input | Genome-scale model, exchange flux measurements, objective function. | Tracer experiment data, extracellular fluxes, network model. |

| Flux Output | Theoretical, relative flux distribution. | Experimentally determined, absolute flux values (mmol/gDW/h). |

| Key Assumptions | Steady-state metabolism, optimal cellular behavior. | Metabolic & isotopic steady-state, well-mixed intracellular pools. |

| Temporal Resolution | Single time-point (steady-state). | Primarily steady-state; dynamic versions (INST-13C-MFA) exist. |

| Throughput | High (computational). | Low to medium (requires wet-lab experiments). |

| Cost | Low (computational). | High (isotope tracers, MS instrument time, analysis). |

| Accuracy vs. Reality | Can be inaccurate if optimization objective is wrong. | Considered the gold standard for empirical flux quantification. |

| Primary Use Case | Hypothesis generation, pathway analysis, strain design in silico. | Validation of model predictions, elucidation of pathway operation. |

Supporting Experimental Data: A 2023 study in Metabolic Engineering compared FBA predictions with 13C-MFA measured fluxes in E. coli central carbon metabolism. Key findings are summarized below.

Table 2: Comparison of Predicted vs. Measured Central Carbon Metabolism Fluxes in E. coli

| Reaction (Flux) | FBA Prediction (mmol/gDW/h) | 13C-MFA Measurement (mmol/gDW/h) | Discrepancy (%) |

|---|---|---|---|

| Glycolysis (G6P → PYR) | 12.5 | 10.2 | +22.5% |

| Pentose Phosphate Pathway (G6P Dehydrogenase) | 1.8 | 3.1 | -41.9% |

| TCA Cycle (Citrate Synthase) | 4.2 | 5.5 | -23.6% |

| Anaplerotic (PEP Carboxylase) | 1.5 | 2.8 | -46.4% |

| Transhydrogenase (NADPH production) | 0.3 | 1.7 | -82.4% |

Data adapted from Schmidt et al., 2023. The study concluded that FBA incorrectly underestimated PPP and NADPH-generating fluxes due to an inaccurate biomass composition objective function, which was corrected using 13C-MFA data.

Experimental Protocols for 13C-MFA

Tracer Experiment Design & Cultivation

Objective: Introduce a 13C-labeled substrate (tracer) to generate uniquely labeled metabolic intermediates.

- Protocol: Cells are cultivated in a controlled bioreactor or shake flask with a defined medium where one or more carbon sources are replaced with a 13C-labeled version (e.g., [1-13C]glucose, [U-13C]glucose). Cultivation proceeds until metabolic steady-state is reached (constant biomass composition and extracellular metabolite concentrations). For microbial systems, this is often achieved in continuous chemostat culture or during mid-exponential batch phase. Cells are then rapidly quenched (e.g., in cold methanol) and harvested for analysis.

Mass Spectrometry (MS) Measurement of Labeling Patterns

Objective: Quantify the isotopic labeling distribution (isotopologue abundances) in proteinogenic amino acids or metabolic intermediates.

- Protocol:

- Hydrolysis & Derivatization: Harvested biomass is hydrolyzed with 6M HCl at 105°C for 24h to break down proteins into free amino acids. Amino acids are then chemically derivatized (e.g., with N(tert-butyldimethylsilyl)-N-methyltrifluoroacetamide, MTBSTFA) to make them volatile for GC-MS.

- GC-MS Analysis: Derivatized samples are injected into a Gas Chromatograph (GC) coupled to an Electron Impact Ionization Mass Spectrometer (EI-MS). The GC separates the amino acids, and the MS fragments each molecule, producing mass spectra.

- Data Processing: The mass isotopomer distribution (MID) is extracted for each amino acid fragment. The MID represents the relative abundances of molecules with different numbers of 13C atoms (M+0, M+1, M+2, ...).

Isotopomer Modeling & Flux Estimation

Objective: Calculate the metabolic flux map that best fits the experimental MS data.

- Protocol:

- Network Definition: A stoichiometric model of central carbon metabolism is constructed.

- Isotopomer Modeling: Software (e.g., INCA, 13C-FLUX2) simulates the propagation of 13C atoms through the network for a given set of trial fluxes, predicting theoretical MIDs.

- Non-Linear Regression: An optimization algorithm iteratively adjusts the flux values to minimize the difference between the simulated MIDs and the experimental MIDs from GC-MS.

- Statistical Analysis: Confidence intervals for each estimated flux are calculated (e.g., via Monte Carlo sampling) to assess precision.

Visualization of the 13C-MFA Workflow

13C-MFA Experimental and Computational Workflow

Comparative Logic of FBA and 13C-MFA Approaches

The Scientist's Toolkit: Key Research Reagent Solutions for 13C-MFA

Table 3: Essential Materials and Reagents for 13C-MFA

| Item | Function in 13C-MFA |

|---|---|

| 13C-Labeled Substrate (e.g., [U-13C]Glucose, [1-13C]Glutamine) | The tracer molecule that introduces detectable isotopic patterns into metabolism. Purity (>99% 13C) is critical. |

| Defined Culture Medium | A chemically synthesized medium lacking unlabeled carbon sources that would dilute the tracer signal. |

| Quenching Solution (e.g., Cold Aqueous Methanol, -40°C) | Rapidly halts all metabolic activity to "snapshot" the isotopic state of intracellular pools. |

| Acid Hydrolysis Reagents (e.g., 6M HCl) | Breaks down cellular proteins into their constituent amino acids for labeling analysis. |

| Amino Acid Derivatization Agent (e.g., MTBSTFA) | Chemically modifies polar amino acids to volatile tert-butyldimethylsilyl (TBDMS) derivatives for GC-MS analysis. |

| GC-MS System | The core analytical instrument. The Gas Chromatograph (GC) separates metabolites, and the Mass Spectrometer (MS) quantifies their isotopologue distributions. |

| Flux Estimation Software (e.g., INCA, 13C-FLUX2, OpenFlux) | Specialized computational platforms used to build the metabolic network model, simulate isotopic labeling, and perform statistical fitting to estimate fluxes. |

| Isotopic Standard Mixtures | Samples with known isotopic enrichment used to calibrate MS instruments and correct for natural isotope abundance. |

Key Historical Milestones and Foundational Papers in Flux Prediction Methodology

Historical Milestones in Metabolic Flux Prediction

| Year | Milestone / Foundational Paper | Key Contribution | Methodology Introduced/Advanced |

|---|---|---|---|

| 1995 | Varma & Palsson, Biotechnology and Bioengineering | Established constraints-based modeling, foundational FBA framework. | Flux Balance Analysis (FBA) |

| 1999 | Wiechert et al., Metabolic Engineering | Introduced universal framework for stationary 13C-MFA. | 13C Metabolic Flux Analysis (13C-MFA) |

| 2003 | Price et al., Nature Reviews Microbiology | Comprehensive review formalizing FBA and its genome-scale applications. | Genome-scale FBA |

| 2007 | Sauer, Current Opinion in Biotechnology | High-throughput 13C-MFA with GC-MS, expanding to larger networks. | High-resolution 13C-MFA |

| 2010 | Lewis et al., Molecular Systems Biology | Integrated regulatory constraints into FBA (rFBA). | Regulatory FBA (rFBA) |

| 2012 | Quek et al., Metabolic Engineering | Demonstrated INST-13C-MFA for non-steady-state, dynamic flux estimation. | INST-13C-MFA |

| 2017 | Yurkovich et al., Cell Systems | Advanced mechanistic, model-based design of experiments (DOE) for 13C-MFA. | Model-guided 13C-MFA DOE |

| 2021 | Bren et al., Nature Communications | Machine learning integration with FBA for improved phenotypic prediction. | ML-augmented FBA |

Comparative Performance: FBA vs. 13C-MFA

Table 1: Core Methodological Comparison

| Aspect | Flux Balance Analysis (FBA) | 13C-MFA |

|---|---|---|

| Primary Data | Genome annotation, measured exchange fluxes. | 13C-labeling patterns of metabolites (GC/MS, LC-MS) & exchange fluxes. |

| Core Principle | Optimization (e.g., max growth) within physicochemical constraints. | Isotopic steady-state balancing & non-linear regression. |

| Network Scale | Genome-scale (100s-1000s of reactions). | Medium-scale, core metabolism (10s-100s of reactions). |

| Temporal Resolution | Steady-state prediction; dynamic variants exist (dFBA). | Steady-state; dynamic variants exist (INST-13C-MFA). |

| Key Assumptions | Steady-state, mass balance, optimal cellular behavior. | Isotopic steady-state, metabolic & isotopic steady-state. |

| Primary Output | Potential flux distribution(s). | Measured in vivo flux distribution with confidence intervals. |

| Quantitative Validation | Requires experimental flux data (e.g., from 13C-MFA) for rigorous validation. | Considered the gold standard for in vivo flux validation. |

Table 2: Experimental Performance Comparison in *E. coli (Glucose Minimal Media, Aerobic)*

| Flux Ratio / Parameter | FBA Prediction (Max Growth) | 13C-MFA Measured Mean ± SD (Literature) | Discrepancy Notes |

|---|---|---|---|

| Glycolysis (G6P → PYR) : PP Pentose Phosphate | ~70:30 | ~73:27 ± 3% | Good agreement under standard conditions. |

| TCA Cycle Flux (mmol/gDW/h) | High (coupled to growth) | 8.5 ± 0.7 | FBA often overestimates absolute TCA flux if maintenance is mis-specified. |

| Anaplerotic Flux (PYR → OAA) | Minimal | Significant (~20% of OAA input) | FBA misses non-optimizing metabolic "shunts". |

| Biomass Yield (gDW/mol Glc) | Predicted: 85-95 | Measured: ~80 ± 5 | FBA prediction sensitive to biomass equation accuracy. |

Detailed Experimental Protocols

Protocol 1: Core 13C-MFA Workflow for Steady-State Flux Determination

- Tracer Experiment: Cultivate cells in a defined medium with a single 13C-labeled carbon source (e.g., [1-13C]glucose). Achieve metabolic and isotopic steady-state (≥5 generations).

- Quenching & Extraction: Rapidly quench metabolism (cold methanol), extract intracellular metabolites.

- Derivatization & Measurement: Derivatize metabolites (e.g., TBDMS for amino acids). Analyze via GC-MS. Acquire mass isotopomer distributions (MIDs) of proteinogenic amino acids.

- Network Definition: Construct atom-mapping model of central carbon metabolism.

- Flux Estimation: Use software (e.g., INCA, 13C-FLUX2) to fit simulated MIDs to experimental MIDs via non-linear least-squares regression, yielding net and exchange fluxes with confidence intervals.

Protocol 2: Constraint-Based FBA for Flux Prediction

- Reconstruction: Build a genome-scale metabolic network (GEM) from annotation (e.g., using ModelSEED, CarveMe). Ensure mass and charge balance.

- Constraint Application: Define system boundary (exchange fluxes). Apply measured substrate uptake/secretion rates as bounds. Apply thermodynamic constraints (e.g., irreversibility).

- Objective Function: Define a biologically relevant objective (e.g., maximize biomass reaction).

- Optimization: Solve the linear programming problem: Maximize Z = cTv, subject to S·v = 0 and lb ≤ v ≤ ub*. Perform flux variability analysis (FVA) to assess solution space.

Pathway and Workflow Visualizations

Title: 13C-MFA Experimental and Computational Workflow

Title: Constraint-Based FBA Solution Procedure

Title: Core Central Carbon Metabolism for Flux Studies

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Solution | Function in Flux Prediction Research |

|---|---|

| U-13C or 1-13C Labeled Glucose | Tracer substrate for 13C-MFA; introduces measurable isotopic patterns into metabolism. |

| Siliconized Vials & Cold Methanol | For reproducible, rapid metabolic quenching to capture true intracellular metabolite levels. |

| Derivatization Reagents (e.g., MSTFA, TBDMS) | Chemically modify polar metabolites for volatile, detectable by GC-MS analysis. |

| GC-MS or LC-HRMS System | High-precision measurement of metabolite concentrations and mass isotopomer distributions. |

| INCA (Isotopomer Network Compartmental Analysis) | Software suite for design, simulation, and flux estimation in 13C-MFA. |

| COBRA Toolbox (MATLAB) | Standard software platform for constraint-based modeling, FBA, and variant analyses. |

| Defined Minimal Media Kits | Ensure reproducible culturing conditions essential for both FBA validation and 13C-MFA. |

| Genome-Scale Model Database (e.g., BiGG Models) | Curated, standardized metabolic reconstructions for FBA. |

This guide compares the performance and application of Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA) in predicting intracellular metabolic fluxes. The comparison is critical for researchers in systems biology and metabolic engineering who require accurate flux maps for applications ranging from biotechnology to drug target identification.

Core Concepts Comparison

| Term | Definition | Primary Application |

|---|---|---|

| Steady-State Assumption | The assumption that the concentrations of intracellular metabolites do not change over time. | Foundation for FBA, requiring constant pool sizes for constraint-based modeling. |

| Isotopic Steady-State | The state where the fractional labeling of metabolite pools from a 13C-labeled tracer becomes constant over time. | Prerequisite for standard 13C-MFA, enabling measurement of net fluxes through metabolic pathways. |

| Flux Balance Analysis (FBA) | A constraint-based modeling approach that uses mass-balance and steady-state assumptions to predict steady-state metabolic reaction rates (fluxes). | Genome-scale flux prediction, strain design, and hypothesis generation. |

| 13C-Metabolic Flux Analysis (13C-MFA) | An experimental approach that uses 13C-labeling patterns in metabolites measured via MS or NMR, combined with a metabolic network model, to quantify in vivo metabolic fluxes. | High-resolution, quantitative flux maps in central carbon metabolism for validation and discovery. |

Performance & Data Comparison: FBA vs. 13C-MFA

Table 1: Methodological and Performance Comparison

| Feature | Flux Balance Analysis (FBA) | 13C-Metabolic Flux Analysis (13C-MFA) |

|---|---|---|

| Core Requirement | Genome-scale metabolic reconstruction; Steady-state assumption. | Defined network model (often core); Isotopic steady-state. |

| Measured Data Used | Typically none (constraint-based); can integrate uptake/secretion rates. | 13C-labeling patterns of metabolites (via GC-MS or LC-MS); extracellular fluxes. |

| Flux Resolution | Cannot differentiate between parallel pathways (e.g., PPF vs. ED pathway) without additional constraints. | Can resolve parallel, reversible, and cyclic fluxes within the modeled network. |

| Scale | Genome-scale (1000s of reactions). | Limited to central metabolism (50-200 reactions) due to experimental complexity. |

| Quantitative Accuracy | Predicts flux distributions; absolute accuracy requires validation. | Considered the gold standard for in vivo quantitative flux measurement in core metabolism. |

| Temporal Resolution | Static (steady-state snapshot). | Static (snapshot at isotopic steady-state, typically after hours). |

| Key Output | A range of possible flux distributions; often presents a single optimal solution (e.g., max growth). | A statistically fitted, unique set of net and exchange fluxes with confidence intervals. |

| Primary Limitation | Relies on optimization principle (e.g., biomass maximization) which may not reflect in vivo conditions. | Experimentally intensive, limited network scale, requires isotopic steady-state. |

Table 2: Example Comparative Flux Data from a *Bacillus subtilis Study*

| Metabolic Reaction Flux (mmol/gDW/h) | FBA Prediction (Max Growth) | 13C-MFA Measured Flux | Relative Discrepancy |

|---|---|---|---|

| Glycolysis (Glucose → G6P) | 10.5 | 8.2 ± 0.3 | +28% |

| Pentose Phosphate Pathway (G6P Dehydrogenase) | 1.1 | 2.4 ± 0.2 | -54% |

| Citrate Synthase | 8.7 | 7.1 ± 0.4 | +23% |

| Malic Enzyme | 0.3 | 1.5 ± 0.2 | -80% |

| Anaplerotic Flux (PEP → OAA) | 1.8 | 3.0 ± 0.3 | -40% |

Data synthesized from recent literature on microbial flux comparisons. 13C-MFA values show mean ± typical standard error.

Experimental Protocols

Key Protocol 1: Standard Workflow for 13C-MFA Flux Determination

- Tracer Experiment Design: Select a 13C-labeled substrate (e.g., [1-13C]glucose). Grow cells in a controlled bioreactor under metabolic steady-state conditions (chemostat).

- Quenching & Extraction: Rapidly quench metabolism (e.g., cold methanol), extract intracellular metabolites.

- Derivatization & Measurement: Derivatize metabolites (e.g., to TBDMS for amino acids) and analyze by Gas Chromatography-Mass Spectrometry (GC-MS).

- Data Processing: Correct mass spectrometry data for natural isotope abundances and calculate Mass Isotopomer Distributions (MIDs).

- Network Modeling & Flux Estimation: Use software (e.g., INCA, 13CFLUX2) to fit fluxes to the measured MIDs via iterative computational search, minimizing the residual between simulated and measured labeling.

- Statistical Analysis: Perform sensitivity analysis and Monte Carlo simulations to estimate confidence intervals for each calculated flux.

Key Protocol 2: FBA Workflow for Flux Prediction

- Model Curation: Obtain a genome-scale metabolic reconstruction (GEM) for the organism.

- Define Constraints: Apply constraints based on known physiology: substrate uptake rates, oxygen uptake, ATP maintenance requirements, and reaction reversibility.

- Define Objective Function: Typically set biomass production as the objective function to maximize.

- Solve Linear Programming Problem: Use a solver (e.g., COBRA Toolbox in MATLAB/Python) to find the flux distribution that optimizes the objective while satisfying all constraints.

- Solution Space Analysis: Explore alternative optimal solutions or flux variability ranges.

Pathway & Workflow Visualizations

Workflow Comparison of FBA and 13C-MFA

Progression to Isotopic Steady-State

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in FBA/13C-MFA Research |

|---|---|

| 13C-Labeled Tracers ([1-13C]Glucose, [U-13C]Glutamine) | Essential substrates for 13C-MFA experiments. Their specific labeling pattern provides the informational input for flux calculation. |

| Chemostat Bioreactor | Enables cultivation of cells at a defined, metabolic steady-state, a prerequisite for both FBA assumptions and interpretable 13C-MFA. |

| GC-MS or LC-MS System | The core analytical instrument for measuring the mass isotopomer distributions (MIDs) of metabolites in 13C-MFA. |

| Metabolic Reconstruction Database (e.g., ModelSeed, BIGG) | Provides curated, genome-scale metabolic network models essential for initiating FBA and structuring 13C-MFA network models. |

| Flux Analysis Software (INCA, 13CFLUX2, COBRA Toolbox) | INCA/13CFLUX2 are used for 13C-MFA computational fitting. COBRA is the standard suite for constraint-based modeling and FBA. |

| Isotopic Natural Abundance Correction Software | Critical for accurately processing raw MS data by subtracting the background signal from naturally occurring isotopes. |

| Quenching Solution (e.g., -40°C 60% Methanol) | Rapidly halts metabolic activity to preserve the in vivo labeling state of metabolites for accurate extraction. |

| Linear Programming Solver (e.g., Gurobi, CPLEX) | The computational engine that solves the optimization problem at the heart of FBA to find a flux distribution. |

From Theory to Bench: A Step-by-Step Guide to Implementing FBA and 13C-MFA in Biomedical Research

Within a broader thesis comparing Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA) for predictive accuracy, the construction of a high-quality Genome-Scale Model (GEM) is the foundational step for FBA. This guide compares prevalent software platforms and methodologies for GEM curation, gap-filling, and constraint definition, supported by recent experimental benchmarks.

Comparative Analysis of GEM Reconstruction Platforms

The following table compares key platforms for building and curating genome-scale metabolic models, based on recent (2023-2024) performance studies.

Table 1: Comparison of GEM Reconstruction & Curation Platforms

| Platform/Tool | Primary Function | Input Requirements | Key Strength | Reported Consistency with 13C-MFA Data (E. coli core model) | Reference |

|---|---|---|---|---|---|

| ModelSEED / KBase | Automated reconstruction from genome annotation. | Genome sequence (FASTA) or annotation (GFF). | High-speed draft model generation. | ~65-70% of major flux predictions within 2σ of 13C-MFA. | (Seavert et al., 2023) |

| RAVEN Toolbox 2.0 | MATLAB-based manual curation & reconstruction. | Template model, homology data. | Superior manual curation and integration of experimental data. | ~80-85% within 2σ after expert curation. | (Wang et al., 2023) |

| CarveMe | Top-down reconstruction from universal model. | Genome annotation, optional bibliomic data. | Generation of taxon-specific, parsimonious models. | ~70-75% within 2σ. | (D’Oltrano et al., 2024) |

| Merlin 4.0 | Integrated annotation and draft reconstruction. | Genome sequence, extensive bibliomic data. | Comprehensive integration of genomic and bibliomic context. | N/A (Focus on draft quality). | (Moreira et al., 2023) |

| MetaDraft | Consensus model generation from multiple tools. | Outputs from ≥2 other reconstruction tools. | Improved robustness by merging multiple drafts. | ~78% within 2σ (consensus vs. single tool). | (Balakrishnan & Reo, 2024) |

Gap-Filling Algorithm Performance

Gap-filling resolves network incompleteness by adding reactions to allow growth or metabolite production. Performance is measured by the biological veracity of added reactions.

Table 2: Comparison of Gap-Filling Algorithms

| Algorithm (Package) | Strategy | Experimental Validation Rate* | Tendency to Introduce Thermodynamically Infeasible Cycles |

|---|---|---|---|

| fastGapFill (MATLAB) | Mixed-Integer Linear Programming (MILP) minimizing added reactions. | 68% | Low |

| GapFill (ModelSEED) | Linear Programming (LP) minimizing flux through added reactions. | 62% | Moderate |

| meneco (Python) | Logic-based completion using reaction databases. | 71% | Very Low |

| Growth Supported Gap Filling (CarveMe) | Requires growth as objective; uses universal model. | 65% | Low |

Percentage of algorithm-suggested reactions confirmed by genomic or enzymological evidence in *S. cerevisiae iMM904 model gap-filling study (Piotrowski & Simeonidis, 2023).

Experimental Protocol: Benchmarking Gap-Filling Algorithms

- Model Preparation: Start with a curated core model (e.g., E. coli iJO1366). Artificially remove known essential reactions to create "gapped" models.

- Database: Use a standardized reaction database (e.g., MetaCyc) as the source for candidate reactions.

- Gap-Filling Execution: Run each algorithm to fill the model to meet a defined objective (e.g., growth on glucose minimal medium).

- Validation: Compare algorithm-added reactions to:

- Genomic evidence (e.g., presence of encoding gene).

- Literature evidence of enzyme activity in the organism.

- Ability to improve FBA flux prediction correlation against 13C-MFA benchmarks.

Defining Physiological Constraints for FBA

The accuracy of FBA predictions relative to 13C-MFA depends critically on applied constraints.

Table 3: Impact of Constraint Types on FBA vs. 13C-MFA Correlation

| Constraint Type | Data Source | Typical Method of Integration | Improvement in R² vs. Unconstrained FBA* |

|---|---|---|---|

| Reaction Directionality | Thermodynamics (e.g., component contribution) | Irreversible bounds (0, ∞). | +0.15 |

| Enzyme Capacity (kcat) | Proteomics + enzyme kinetics databases | Upper bound = [Enzyme] × kcat. | +0.28 |

| Substrate Uptake | Extracellular flux measurements (e.g., MFA) | Fixed lower/upper bounds. | +0.22 |

| Transcriptomics | RNA-seq data | Linear mapping (e.g., GIM3E) to set flux bounds. | +0.10 |

| Competitive Proteomics | 13C-based proteomics | Constrain total enzyme mass per reaction. | +0.35 |

Synthetic benchmark on *B. subtilis model; R² of central carbon metabolism fluxes vs. 13C-MFA reference (Kim et al., 2024).

Experimental Protocol: Incorporating Enzyme Capacity Constraints

- Proteomics Measurement: Quantify absolute enzyme abundances (mmol/gDW) using LC-MS/MS.

- kcat Assignment: Assign turnover numbers from databases (e.g., SABIO-RK, BRENDA) using organism-specific or enzyme-specific values where available.

- Constraint Calculation: For each reaction i, calculate maximum capacity: v_i,max = [E_i] × kcat_i.

- FBA Implementation: Apply v_i,max as an upper bound in the linear programming problem. If isozymes exist, the sum of their fluxes is constrained.

- Validation: Compare predicted growth rates and central carbon fluxes against 13C-MFA data.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents & Kits for GEM-Related Experimental Validation

| Item | Function in GEM Development/Validation |

|---|---|

| 13C-Labeled Substrates (e.g., [U-13C] Glucose) | Essential for 13C-MFA experiments, which serve as the gold-standard benchmark for validating FBA flux predictions. |

| LC-MS/MS System | Quantifies extracellular metabolites, intracellular metabolites for MFA, and absolute protein abundances for enzyme constraint data. |

| Absolute Quantification Proteomics Kit (e.g., Spike-in TMT) | Enables precise measurement of enzyme concentrations per gDW for capacity constraints. |

| Rapid Metabolite Extraction Kits (Quenching & Extraction) | Provides accurate snapshots of intracellular metabolic states for integration with FBA. |

| Genomic DNA Extraction Kit | High-quality genomic DNA is the starting material for sequencing and annotation required for draft reconstruction. |

| Automated Microbial Cultivation System (e.g., Bioreactor, Microfluidic) | Generates reproducible, steady-state growth data for constraint definition (uptake/secretion rates, growth rates). |

Visualizations

GEM Construction and Validation Workflow

Data Integration for Model Constraints

Within the context of flux balance analysis (FBA) versus 13C-metabolic flux analysis (13C-MFA) prediction comparison research, the choice of isotopic tracer is paramount. FBA provides a static, stoichiometric network prediction of fluxes, while 13C-MFA uses empirical labeling data to determine in vivo metabolic activity. The substrate's labeling pattern directly influences the precision, scope, and statistical confidence of the resolved flux map. This guide compares common 13C-labeled glucose tracers for elucidating central carbon metabolism.

Comparison of Common 13C-Glucose Tracers

The selection of a tracer involves trade-offs between cost, informational content, and experimental goals. The table below summarizes key performance metrics for four widely used glucose tracers in a typical mammalian cell culture experiment.

Table 1: Performance Comparison of 13C-Labeled Glucose Substrates

| Tracer Substrate | Relative Cost (per mmol) | Primary Metabolic Pathways Illuminated | Key Differentiation Power | Statistical Confidence (Minimal Flux SD)* |

|---|---|---|---|---|

| [1-13C]Glucose | $ | Glycolysis, PPP Oxidative Phase, TCA Cycle (first turn) | Low for parallel pathways | ± 15-25% |

| [U-13C]Glucose | $$$$$ | Entire network activity | High global resolution | ± 5-12% |

| [1,2-13C]Glucose | $$ | Glycolysis, PPP, Anaplerosis, TCA Cycle | High for PPP vs. Glycolysis & TCA cycle reversibility | ± 8-15% |

| [6-13C]Glucose | $ | Lower Glycolysis, TCA Cycle | Low; often used in combination | ± 18-30% |

*Hypothetical values for representative fluxes (e.g., PPP flux, pyruvate carboxylase flux) based on simulated data from 13C-MFA software (e.g., INCA, 13CFLUX2). Actual SD depends on network model, measurement noise, and culture conditions.

Experimental Data from Tracer Comparisons

A pivotal study comparing FBA predictions to 13C-MFA fluxes used multiple tracers to validate findings. The data below highlights how tracer choice impacts the ability to discriminate between FBA-predicted and empirically measured fluxes.

Table 2: Experimental Flux Data for CHO Cells Cultured on Different Tracers (Normalized to Glucose Uptake = 100)

| Metabolic Flux | FBA Prediction | [U-13C]Glucose MFA | [1,2-13C]Glucose MFA | Key Insight |

|---|---|---|---|---|

| Pentose Phosphate Pathway (PPP) Net Flux | 20 | 65 ± 5 | 62 ± 8 | FBA under-predicts PPP. [1,2-13C] provides robust PPP estimation. |

| Pyruvate Carboxylase (PC) Flux | 0 | 25 ± 3 | 24 ± 6 | FBA missed anaplerosis. Both tracers detect it, [U-13C] offers higher precision. |

| Malic Enzyme Flux | 15 | 5 ± 2 | 8 ± 5 | FBA over-predicts. [1,2-13C] allows estimation but with lower confidence. |

| Glycolysis (PYK) Flux | 80 | 110 ± 7 | 108 ± 10 | Both tracers correct the FBA estimate effectively. |

Detailed Protocol: 13C-Tracer Experiment with [1,2-13C]Glucose

1. Cell Culture and Labeling:

- Seed Chinese Hamster Ovary (CHO) cells in 6-well plates in standard growth medium. Grow to ~80% confluence.

- Wash cells twice with warm, isotope-free PBS.

- Add pre-warmed labeling medium: Glucose-free DMEM supplemented with 10 mM [1,2-13C]glucose (≥99% atom purity), 4 mM L-glutamine, and 10% dialyzed FBS.

- Incubate cells for a duration equal to at least two population doubling times (typically 24-48h) to achieve isotopic steady state in metabolic intermediates.

2. Metabolite Extraction and Derivatization:

- Quench metabolism rapidly by removing medium and adding 1 mL of -20°C 40:40:20 methanol:acetonitrile:water.

- Scrape cells and transfer suspension to a -80°C freezer for 30 min.

- Centrifuge at 16,000 x g for 15 min at 4°C. Transfer supernatant (polar metabolome) to a new tube.

- Dry samples using a vacuum concentrator.

- Derivatize for GC-MS: Add 20 µL of 15 mg/mL methoxyamine hydrochloride in pyridine, incubate at 70°C for 1h. Then add 80 µL N-tert-Butyldimethylsilyl-N-methyltrifluoroacetamide (MTBSTFA), incubate at 70°C for 1h.

3. GC-MS Analysis and Data Processing:

- Inject 1 µL of derivatized sample in splitless mode onto a DB-35MS column.

- Use electron impact ionization (70 eV) and operate in selected ion monitoring (SIM) mode to collect mass isotopomer distributions (MIDs) for key metabolite fragments (e.g., alanine m/z 260, glutamate m/z 432).

- Integrate peak areas for each mass isotopomer (M0, M1, M2...).

- Correct MIDs for natural isotope abundance using software like IsoCor or MeltDB.

Experimental Workflow Diagram

Title: 13C-MFA Experimental and Computational Workflow

Tracer Decision Logic for FBA vs. 13C-MFA Research

Title: Decision Tree for Selecting a 13C-Glucose Tracer

The Scientist's Toolkit: Key Reagent Solutions

Table 3: Essential Materials for a 13C-Tracer Experiment

| Item | Function | Example Product/Catalog # |

|---|---|---|

| 13C-Labeled Glucose | Tracer substrate; introduces measurable isotopic pattern into metabolism. | [1,2-13C]Glucose, 99% (CLM-504-MT) |

| Glucose-Free Medium | Base medium formulation to ensure the labeled substrate is the sole carbon source. | DMEM, no glucose (11966025) |

| Dialyzed Fetal Bovine Serum (FBS) | Provides essential proteins and growth factors without unlabeled carbon sources that would dilute the tracer. | Dialyzed FBS (A3382001) |

| Methanol, Acetonitrile (LC-MS Grade) | Components of quenching/extraction solvent; rapidly halt metabolism and extract polar metabolites. | LC-MS Grade Solvents |

| Methoxyamine Hydrochloride | Derivatization agent; protects carbonyl groups prior to silylation for GC-MS. | Methoxyamine HCl (226904) |

| MTBSTFA | Silylation derivatization agent; increases volatility of metabolites for GC-MS analysis. | N-(tert-Butyldimethylsilyl)-N-methyltrifluoroacetamide (375934) |

| GC-MS System | Instrumentation for separating and detecting mass isotopomers of derivatized metabolites. | Agilent 8890 GC / 5977B MSD |

| 13C-MFA Software | Computational platform to fit corrected labeling data to a metabolic model and estimate fluxes. | INCA, 13CFLUX2, OpenFLUX |

Flux Balance Analysis (FBA) is a cornerstone constraint-based modeling approach in systems biology. This guide compares the performance of FBA in predicting gene essentiality, growth phenotypes, and synthetic lethality against alternative experimental and computational methods, such as 13C-Metabolic Flux Analysis (13C-MFA) and gene knockout screens. The discussion is framed within the broader thesis of comparing FBA's in silico predictions with the in vivo flux measurements provided by 13C-MFA.

Comparison Guide 1: Gene Essentiality Prediction

Performance Summary: FBA predicts gene essentiality by simulating knockout of metabolic genes and assessing growth rate. Its accuracy is benchmarked against experimental essentiality data from large-scale knockout libraries (e.g., Keio collection for E. coli).

| Metric | FBA (Genome-Scale Model) | Experimental Knockout Screen (Reference) | Alternative Method: Machine Learning (ML) on Omics Data) |

|---|---|---|---|

| Average Accuracy (E. coli) | 88-92% | 100% (by definition) | 85-90% |

| Precision (Essential Genes) | 90% | 100% | 88% |

| Recall (Essential Genes) | 85% | 100% | 82% |

| Key Advantage | Mechanistic, provides flux rationale; fast genome-scale screening. | Ground truth. | Can integrate non-metabolic factors; pattern recognition. |

| Key Limitation | Misses non-metabolic essential genes; depends on model completeness. | Experimentally intensive; low-throughput for complex organisms. | "Black box"; requires large training datasets. |

Experimental Protocol for FBA-Based Essentiality Prediction:

- Model Curation: Obtain a genome-scale metabolic reconstruction (e.g., iML1515 for E. coli).

- Knockout Simulation: For each gene

G, constrain the flux(es) of its associated reaction(s) to zero. - Growth Simulation: Perform FBA, maximizing for the biomass reaction (

v_biomass) as the objective function. - Classification: If the predicted optimal

v_biomass< 0.01 (or a defined threshold) of the wild-type value, geneGis predicted as essential. Otherwise, it is non-essential. - Validation: Compare predictions to an experimental gold-standard dataset. Discrepancies drive model refinement.

Comparison Guide 2: Quantitative Growth Phenotype Prediction

Performance Summary: FBA predicts quantitative growth rates (e.g., in different carbon sources) which are compared to measured growth yields and rates, as well as fluxes from 13C-MFA.

| Metric | FBA | 13C-MFA (Reference) | Alternative: dFBA (Dynamic FBA) |

|---|---|---|---|

| Correlation (R²) with Measured Growth Yield | 0.75-0.85 | Not Applicable (measures fluxes) | 0.80-0.90 |

| Correlation with Central Carbon Fluxes | 0.60-0.75 | 1.00 (by definition) | 0.65-0.78 |

| Temporal Resolution | Steady-state only | Steady-state only | Pseudo-dynamic |

| Key Advantage | High-throughput; predicts absolute growth yield. | Gold-standard for in vivo flux measurement. | Captures dynamic nutrient shifts. |

| Key Limitation | Poor correlation for certain substrate fluxes; assumes optimality. | Technically complex; low throughput; requires isotopic labeling. | More complex parametrization. |

Experimental Protocol for 13C-MFA Validation:

- Cultivation: Grow cells in a chemostat or batch culture with a defined 13C-labeled substrate (e.g., [1-13C]glucose).

- Harvest: Quench metabolism and extract metabolites (e.g., proteinogenic amino acids).

- Measurement: Use GC-MS or NMR to measure the mass isotopomer distribution (MID) of the metabolites.

- Flux Estimation: Use a metabolic network model and computational fitting (e.g., INCA software) to estimate intracellular fluxes that best explain the measured MID.

- Comparison: Statistically compare the estimated in vivo fluxes from 13C-MFA to the FBA-predicted flux distributions for the same condition.

Comparison Guide 3: Synthetic Lethality Prediction

Performance Summary: FBA identifies synthetic lethal gene pairs where the simultaneous knockout stops growth, but individual knockouts do not. This is compared to genetic interaction screens.

| Metric | FBA (Double Knockout) | Experimental Genetic Interaction Mapping (e.g., E-MAP) | Alternative: Parsimonious FBA (pFBA) |

|---|---|---|---|

| Precision (in S. cerevisiae metabolism) | ~30% | 100% (by definition) | ~35% |

| Recall (in S. cerevisiae metabolism) | ~22% | 100% | ~25% |

| Throughput | Very High (All model gene pairs) | High but experimental | Very High |

| Key Advantage | Guides high-cost experiments; provides metabolic mechanisms. | Direct experimental observation, captures all biological processes. | Reduces false positives by assuming flux parsimony. |

| Key Limitation | High false positive rate; limited to metabolic interactions. | Resource-intensive; not all organisms. | Still limited to metabolism. |

Experimental Protocol for Genetic Interaction Screening (E-MAP):

- Strain Construction: Create a comprehensive array of single-gene deletion mutants in a model organism (e.g., yeast).

- Crossing: Use robotic mating to generate double deletion mutants for a selected set of genes.

- Phenotyping: Quantify fitness (e.g., colony size) for each single and double mutant under a specific condition.

- Scoring: Calculate a genetic interaction score (ε) based on the deviation of the double mutant's fitness from the expected multiplicative effect of the two single mutants. Negative scores indicate synthetic sickness/lethality.

- Validation: Compare high-scoring interactions from the screen to FBA-predicted synthetic lethal pairs.

Visualizations

Title: FBA Prediction and Validation Workflow

Title: FBA vs 13C-MFA Comparison Thesis Context

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in FBA/Validation Research |

|---|---|

| Genome-Scale Model (e.g., iML1515, Yeast8) | A computational reconstruction of metabolism used as the core framework for FBA simulations. |

| Constraint-Based Modeling Software (COBRApy, RAVEN) | Toolboxes to implement FBA, gene knockouts, and predict phenotypes. |

| 13C-Labeled Substrates (e.g., [U-13C]Glucose) | Tracers required for 13C-MFA experiments to elucidate in vivo metabolic fluxes. |

| GC-MS or NMR Instrumentation | Essential for measuring mass isotopomer distributions from 13C-labeling experiments. |

| Flux Estimation Software (INCA, IsoCor2) | Used to fit 13C-MFA data to metabolic models and calculate intracellular fluxes. |

| Mutant Library (e.g., Keio, Yeast Knockout) | Experimental gold-standard collections for validating gene essentiality predictions. |

| Chemostat Bioreactor | Provides a steady-state culture environment crucial for both 13C-MFA and quantitative growth phenotyping. |

This guide compares the performance of 13C-Metabolic Flux Analysis (13C-MFA) against alternative flux quantification methods, primarily Flux Balance Analysis (FBA). The comparison is framed within ongoing research assessing the accuracy and applicability of these tools for two critical fields: understanding cancer metabolism and optimizing microbial cell factories. 13C-MFA provides in vivo, experimentally measured fluxes, serving as a gold standard for validating in silico predictions from constraint-based models like FBA.

Performance Comparison: 13C-MFA vs. FBA

The table below summarizes a comparative analysis of 13C-MFA and FBA based on key performance criteria relevant to metabolic engineering and cancer research.

Table 1: Comparative Analysis of 13C-MFA and FBA for Flux Prediction

| Criterion | 13C-MFA | Flux Balance Analysis (FBA) | Supporting Experimental Data |

|---|---|---|---|

| Core Principle | Experimental fitting of isotopic labeling data to a metabolic network model. | Mathematical optimization of an objective function (e.g., growth) constrained by stoichiometry. | (Antoniewicz et al., Metab Eng, 2007): Demonstrated precise flux determination in E. coli via [1,2-13C]glucose tracing, providing a benchmark dataset. |

| Primary Output | Quantitative, in vivo net and exchange fluxes at a branch point. | A theoretically possible flux distribution; often a single optimal solution. | (Crown et al., Nat Commun, 2016): 13C-MFA in pancreatic cancer cells revealed divergent glycine metabolism fluxes not predicted by stoichiometric models alone. |

| Requirement for Measurements | Requires extensive extracellular rate measurements and mass isotopomer distribution (MID) data from LC-MS/GC-MS. | Requires only a genome-scale model and exchange flux constraints (e.g., substrate uptake). | (Yoo et al., Anal Chem, 2008): Protocol for precise measurement of extracellular uptake/secretion rates, a critical input for 13C-MFA. |

| Predictive vs. Observational | Observational and descriptive; quantifies fluxes occurring under the experimental condition. | Inherently predictive; can simulate gene knockouts or nutrient shifts. | (Long & Antoniewicz, PNAS, 2019): Parallel labeling experiments proved 13C-MFA can be used for prediction by directly measuring flux changes in response to perturbations. |

| Accuracy & Validation | Considered an empirical gold standard; validates and refines genome-scale models. | Predictions are hypothetical and require experimental validation (e.g., by 13C-MFA). | (Gopalakrishnan & Maranas, Metab Eng, 2015): Study showed FBA predictions of knockout strains often diverged from 13C-MFA-measured fluxes, highlighting the need for validation. |

| Throughput & Cost | Low to medium throughput; high cost per sample due to labeling experiments and advanced instrumentation. | Very high throughput; low computational cost per simulation. | (Noh et al., Biotechnol Bioeng, 2006): Established computational methods to minimize the number of 13C labeling experiments required, addressing throughput limitations. |

| Application in Cancer | Identifies in vivo pathway activities in tumors (e.g., TCA cycle anaplerosis, redox balance). | Hypothesizes metabolic vulnerabilities and essential genes for proliferation. | (Hensley et al., Cell, 2016): 13C-MFA in human lung tumors in vivo quantified glutamine contribution to the TCA cycle, a flux FBA could suggest but not quantify. |

| Application in Microbial Engineering | Precisely measures carbon partitioning to target product vs. biomass, guiding strain optimization. | Rapidly screens thousands of genetic designs for theoretical yield. | (Suthers et al., Metab Eng, 2021): 13C-MFA in an engineered E. coli strain quantified the flux through a synthetic non-oxidative glycolysis (NOG) pathway, confirming its function and efficiency beyond FBA predictions. |

Experimental Protocols for Key Comparisons

Protocol 1: Validating FBA Predictions with 13C-MFA (Core Comparison Workflow)

- FBA Simulation: For a given organism (e.g., E. coli or a cancer cell line reconstruction), run FBA with an objective (e.g., maximize biomass) under defined medium conditions. Record the predicted internal flux distribution, particularly at key branch points (e.g., PEP/pyruvate node).

- Experimental Cultivation: Grow the biological system in a bioreactor or controlled culture system with a defined 13C-labeled substrate (e.g., [U-13C]glucose). Ensure metabolic and isotopic steady-state is reached.

- Metabolite Extraction & Analysis: Quench metabolism rapidly. Extract intracellular metabolites. Derivatize if necessary. Analyze mass isotopomer distributions (MIDs) of proteinogenic amino acids or central metabolites using Gas Chromatography-Mass Spectrometry (GC-MS).

- 13C-MFA Computational Analysis: Use software (e.g., INCA, Isotopomer Network Compartmental Analysis) to fit the experimental MIDs and extracellular rates to a metabolic network model. Obtain the statistically best-fit flux map with confidence intervals.

- Comparison: Overlay the FBA-predicted fluxes and the 13C-MFA measured fluxes on the network map. Calculate correlation coefficients (e.g., Pearson's R) and mean absolute error for major pathways.

Protocol 2: Quantifying Cancer-Specific Pathway Fluxes with 13C-MFA

- Tracer Design: Select a tracer that elucidates the pathway of interest. To study glutamine metabolism, use [U-13C]glutamine.

- In Vitro Tracing: Culture cancer cell lines in media where 100% of the glutamine is replaced by the 13C-labeled version. Harvest cells at isotopic steady-state (typically 24-48h).

- GC-MS Sample Preparation: Hydrolyze cellular protein to free amino acids. Derivatize amino acids to their tert-butyldimethylsilyl (TBDMS) forms.

- MID Measurement: Acquire mass spectra for fragments of key amino acids (e.g., glutamate from glutamine, aspartate from TCA cycle).

- Flux Elucidation: Input MIDs into 13C-MFA software with a model of central metabolism. Fluxes such as glutaminolysis rate, reductive carboxylation, and oxidative TCA cycle flux will be quantified with confidence intervals.

Visualizing the Workflow and Logical Relationships

Title: 13C-MFA Validation Workflow vs. FBA Predictions

Title: Key Flux Questions Answered by 13C-MFA in Cancer and Engineering

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for 13C-MFA Studies

| Item | Function / Explanation |

|---|---|

| 13C-Labeled Substrates | Chemically defined tracers (e.g., [U-13C]glucose, [1,2-13C]glucose, [U-13C]glutamine). Serve as the metabolic probes to trace carbon fate through networks. |

| Siliconized Culture Ware | Minimizes cell adhesion and metabolite absorption to plastic surfaces, ensuring accurate measurement of extracellular rates and biomass yields. |

| Quenching Solution | Cold, buffered methanol/saline solution. Rapidly halts all metabolic activity to "freeze" the in vivo metabolic state for accurate snapshots. |

| Derivatization Reagents | e.g., Methoxyamine hydrochloride and N-methyl-N-(tert-butyldimethylsilyl)trifluoroacetamide (MTBSTFA). Modify metabolites for volatility and optimal detection by GC-MS. |

| Internal Standards (IS) | Stable isotope-labeled internal standards (e.g., 13C or 2H-labeled metabolites). Added during extraction to correct for losses and matrix effects in MS analysis. |

| Anion/Cation Exchange Columns | Used during metabolite extraction to purify samples, removing salts and interfering compounds prior to MS analysis. |

| GC-MS or LC-MS System | High-resolution mass spectrometer coupled to a separation system. The core instrument for measuring mass isotopomer distributions (MIDs) with high precision. |

| 13C-MFA Software | e.g., INCA, IsoCor, OpenFLUX. Specialized computational platforms for statistical fitting of labeling data to metabolic models and flux calculation. |

This comparison guide, framed within a thesis contrasting Flux Balance Analysis (FBA) and ¹³C-Metabolic Flux Analysis (¹³C-MFA) for flux prediction, objectively evaluates five critical software platforms. Each tool occupies a distinct niche in the constraint-based modeling ecosystem. Performance is assessed based on core functionality, algorithmic implementation, user accessibility, and integration of experimental data, supported by experimental data from recent studies.

Comparison of Software Toolkits for Metabolic Flux Analysis

Table 1: Core Feature and Performance Comparison

| Feature / Metric | COBRA (Toolbox) | OptFlux | INCA | OpenFlux | MetaFluxAnalyser |

|---|---|---|---|---|---|

| Primary Method | FBA, dFBA, pFBA | FBA, Strain Design | ¹³C-MFA | ¹³C-MFA | FBA, Gap-filling |

| Core Algorithm | LP/QP (e.g., Gurobi, GLPK) | MILP, EA | EMU, INST-MFA | EMU, Elementary Metabolite Units | LP, Mixed-integer LP |

| Language/Platform | MATLAB/Octave | Java (Standalone) | MATLAB | MATLAB | Web-based, MATLAB |

| GUI Available | Limited (via third-party) | Yes (Comprehensive) | Yes | No (Script-based) | Yes (Web GUI) |

| Experimental Data Integration | Low (Growth rates, uptake) | Medium (Physiology) | High (MS & NMR data) | High (MS data) | Low (Genomics) |

| Parallel Computation Support | Limited | Limited | Yes (Key for large networks) | Yes | No |

| Typical Runtime for a Midsize Network* | <5 min (FBA) | <10 min (FBA) | Hours to Days (Full ¹³C-MFA) | Hours (Steady-state) | <15 min (Gap-filling) |

| Curated Model Repository | Yes (BiGG, AGORA) | Via SBML | No | No | No |

Runtime based on *E. coli core model (FBA tools) vs. a central carbon model of ~50 reactions (¹³C-MFA tools) on standard workstations.

Detailed Methodologies for Key Experiments

Experiment 1: Comparing FBA vs. ¹³C-MFA Flux Predictions in E. coli

- Objective: Quantify disparities between FBA-predicted and ¹³C-MFA-measured fluxes in central carbon metabolism.

- Protocol:

- Model & Constraint Setup (FBA): Load the E. coli iJO1366 model into COBRApy. Set constraints for glucose uptake (10 mmol/gDW/h) and oxygen uptake (20 mmol/gDW/h). Run pFBA to predict flux distribution.

- ¹³C-Labeling Experiment: Grow E. coli BW25113 in minimal media with [1-¹³C]glucose as the sole carbon source. Harvest cells at mid-exponential phase.

- Mass Spectrometry (MS) Analysis: Derivatize proteinogenic amino acids and measure ¹³C-labeling patterns (mass isotopomer distributions, MIDs) via GC-MS.

- Flux Estimation (¹³C-MFA): Import the stoichiometric model and experimental MIDs into INCA. Use the EMU framework to simulate MIDs and iteratively fit fluxes via non-linear least squares regression. Compute confidence intervals.

- Comparison: Map fluxes from pFBA (COBRA) and ¹³C-MFA (INCA) onto a common network diagram. Calculate normalized root-mean-square deviation (NRMSD) for overlapping reactions.

Experiment 2: Evaluating Strain Design Predictions with Experimental Validation

- Objective: Test the accuracy of OptFlux's strain design algorithms (e.g., OptKnock) by constructing and phenotyping predicted knockout strains.

- Protocol:

- In silico Design: Use OptFlux's "Strain Optimization" module with the E. coli core model. Run OptKnock to identify gene knockout combinations predicted to maximize succinate production under aerobic conditions.

- Strain Construction: Create the top-predicted knockout (e.g., ΔsdhC, ΔptsG) in E. coli using λ-Red recombination.

- Bioreactor Cultivation: Cultivate wild-type and knockout strains in controlled bioreactors with defined media. Monitor growth, substrate consumption, and product formation online.

- Flux Analysis: Perform ¹³C-MFA using OpenFlux on samples from the knockout strain to obtain the actual flux map. Compare the in vivo fluxes to the OptFlux-predicted flux distribution for the engineered network.

Diagrammatic Representations

Diagram 1: FBA vs 13C-MFA Workflow Comparison

Diagram 2: Typical 13C-MFA Computational Pipeline (INCA/OpenFlux)

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for 13C-MFA Experiments

| Item | Function in Flux Analysis |

|---|---|

| [1-¹³C]Glucose | Tracer substrate; labels specific carbon positions, enabling tracing of metabolic pathway activity. |

| Derivatization Reagent (e.g., MTBSTFA) | Chemically modifies amino acids or metabolites for volatility and detection in GC-MS. |

| Internal Standard (e.g., Norvaline) | Added during quenching/extraction to correct for variations in sample processing and injection. |

| QC Reference Material (Uniformly ¹³C-labeled extract) | Validates MS instrument performance and calibration for accurate isotopomer detection. |

| Stable Isotope-Labeled Biomass Standard | Used as a reference for absolute quantification of extracellular flux rates (e.g., substrate uptake). |

| Anion Exchange Resins | Purify charged metabolites (e.g., glycolytic intermediates) from cell extracts prior to MS analysis. |

| Defined, Chemically Minimal Media | Eliminates background carbon sources that would dilute the ¹³C-label, crucial for precise MFA. |

| Metabolite Extraction Solvent (Cold Methanol/Water) | Rapidly quenches metabolism and extracts intracellular metabolites for snapshot flux analysis. |

This comparison guide is framed within a broader thesis research project comparing Flux Balance Analysis (FBA) and 13C-Metabolic Flux Analysis (13C-MFA) for intracellular flux prediction. A key challenge for standard FBA is the lack of biological context, leading to unrealistic flux solutions. Regulatory FBA (rFBA) and GIMME (Gene Inactivity Moderated by Metabolism and Expression) are constraint-based approaches that integrate transcriptomic and proteomic data to guide the model towards a more physiologically relevant flux state. This guide objectively compares the performance, data requirements, and outputs of rFBA and GIMME.

Core Methodology Comparison

Regulatory FBA (rFBA)

rFBA incorporates a regulatory network model alongside the metabolic genome-scale model (GEM). Transcriptomic data (e.g., from microarrays or RNA-seq) is used to infer the on/off state of regulatory genes. This state then activates or represses target metabolic reactions via Boolean logic, effectively turning reactions "on" or "off" in the metabolic model before the FBA optimization step.

GIMME

GIMME uses continuous expression data (transcriptomic or proteomic) to create a context-specific model. It calculates a reaction activity score based on associated gene expression. It then performs FBA with an additional objective: minimize the sum of fluxes through reactions whose activity score falls below a user-defined threshold, while achieving a specified fraction of optimal biomass (or another primary objective).

Performance Comparison: rFBA vs. GIMME

Table 1: Theoretical and Practical Comparison of rFBA and GIMME

| Feature | Regulatory FBA (rFBA) | GIMME |

|---|---|---|

| Core Principle | Boolean regulation integrates transcriptomics to turn reactions ON/OFF. | Quadratic programming minimizes fluxes through low-expression reactions. |

| Omics Data Input | Discrete (ON/OFF) gene states derived from transcriptomics. | Continuous gene/protein expression values (microarray, RNA-seq, proteomics). |

| Primary Constraint | Reaction presence/absence via regulatory rules. | Reaction flux penalty based on expression. |

| Key Requirement | A prior, known regulatory network (Boolean rules). | A gene-protein-reaction (GPR) association map; no regulatory network needed. |

| Output | A single predicted flux distribution consistent with regulation. | A context-specific model and flux distribution that balances growth and expression. |

| Handling Uncertainty | Low; binary rules are strict. | High; uses thresholds and trade-off parameters. |

| Best For | Systems with well-characterized regulatory networks. | Systems where high-throughput omics data exists but regulatory details are limited. |

Table 2: Experimental Performance in E. coli and S. cerevisiae (Synthetic & In Vivo Data)

| Study & Organism | Metric | rFBA Prediction Accuracy | GIMME Prediction Accuracy | 13C-MFA Reference | Notes |

|---|---|---|---|---|---|

| E. coli (Aerobic Growth) [1] | Correlation (R²) of central carbon fluxes vs 13C-MFA | 0.71 | 0.89 | High-resolution 13C-MFA | GIMME outperformed when transcriptomic data matched condition. |

| S. cerevisiae (Diauxic Shift) [2] | Correct prediction of metabolic shift (True/Positive) | True (but delayed timing) | True (accurate timing) | 13C-MFA time-series | rFBA's Boolean rules lacked temporal resolution. |

| E. coli (Gene Knockout) [3] | Prediction of growth/no-growth phenotype | 85% | 78% | Experimental growth data | rFBA excelled with known regulatory responses to knockouts. |

Detailed Experimental Protocols

Protocol 1: Implementing rFBA with Transcriptomic Data

- Model Preparation: Start with a GEM (e.g., iJO1366 for E. coli) and its corresponding Boolean regulatory network.

- Data Processing: Process RNA-seq read counts. Calculate Z-scores and define a threshold (e.g., Z > 1 = "ON", Z < -1 = "OFF", else unchanged).

- State Determination: For each regulatory gene, apply the Boolean rule using the discretized expression states of its inputs.

- Model Constraining: For reactions controlled by these regulators, set their bounds to zero (if repressed) or open (if activated).

- Flux Calculation: Perform parsimonious FBA (pFBA) on the constrained model to obtain a unique flux distribution.

Protocol 2: Implementing GIMME with Proteomic Data

- Model & Data Preparation: Start with a GEM with GPR rules. Map quantitative proteomic abundances (e.g., from LC-MS/MS) to each reaction via its GPR.

- Scoring: Calculate a normalized reaction abundance score (e.g., using the "AND" and "OR" logic in GPRs).

- Thresholding: Define an expression threshold (e.g., percentile of all reaction scores). Reactions below this are "low-expression."

- Optimization: Solve the quadratic programming problem: Minimize Σ (vi)² for low-expression reactions, subject to S•v = 0, and vbiomass ≥ α•vbiomassmax (where α is typically 0.9-0.99).

- Output: The resulting flux vector is the GIMME-predicted flux distribution.

Visualizations

Title: rFBA Workflow Integrating Transcriptomic Data

Title: GIMME Workflow Integrating Proteomic Data

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for rFBA/GIMME Integration Studies

| Item | Function in Experiment | Example Vendor/Catalog |

|---|---|---|

| RNA-seq Kit | Extracts and prepares transcriptomic data for rFBA/GIMME input. | Illumina TruSeq Stranded mRNA Kit |

| LC-MS/MS System | Quantifies protein abundance for proteomic constraints in GIMME. | Thermo Fisher Orbitrap Exploris 480 |

| Stable Isotope Tracers (e.g., [U-13C]Glucose) | Provides experimental flux data via 13C-MFA for validation. | Cambridge Isotope Laboratories CLM-1396 |

| Constriction-Based Modeling Software | Implements rFBA, GIMME, and FBA algorithms. | COBRA Toolbox for MATLAB/Python |

| Curated Genome-Scale Model | Base metabolic network for constraint integration. | BiGG Models (iJO1366, Yeast8) |

| Regulatory Network Database | Provides Boolean rules essential for rFBA. | RegulonDB (for E. coli) |

Solving Common Pitfalls: How to Optimize and Troubleshoot Your FBA and 13C-MFA Workflows

Flux Balance Analysis (FBA) is a cornerstone of constraint-based metabolic modeling. However, its application for quantitative flux prediction is limited by two key issues: non-unique flux solutions (multiple flux distributions yielding identical objective values) and thermodynamic infeasibility (solutions violating the second law). This guide compares the predictive performance of classic FBA against its enhanced counterparts and the gold-standard 13C-Metabolic Flux Analysis (13C-MFA), framed within ongoing research on flux prediction accuracy.

Comparative Analysis: FBA Enhancements vs. 13C-MFA

The following table summarizes the core limitations of standard FBA and how advanced methods address them, with quantitative performance metrics from recent experimental validation studies.

Table 1: Comparison of Flux Prediction Methodologies and Performance

| Method | Core Principle | Key Limitation Addressed | Typical Correlation (R²) with 13C-MFA Data* | Computational Cost | Requirement for Experimental Data |

|---|---|---|---|---|---|

| Standard FBA | Linear optimization of a biomass/rate objective. | None – baseline. | 0.3 - 0.6 | Low | None (only stoichiometry). |

| Parsimonious FBA (pFBA) | Minimizes total enzyme flux while maximizing growth. | Non-unique solutions. | 0.5 - 0.75 | Low | None. |

| Loopless FBA (ll-FBA) | Eliminates thermodynamically infeasible cycles. | Thermodynamic infeasibility. | 0.6 - 0.8 | Moderate-High | None (uses pseudo-energy constraints). |

| Integrative FBA (iFBA) | Incorporates kinetic/regulatory constraints. | Both, partially. | 0.7 - 0.85 | High | Transcriptomic/Proteomic data. |

| 13C-MFA | Fitting to stable isotope labeling patterns. | Gold standard; provides unique, thermodynamically feasible fluxes. | 1.0 (by definition) | Very High | Extensive 13C-labeling data. |

Correlation ranges are illustrative, based on *E. coli and S. cerevisiae central carbon metabolism studies. pFBA and ll-FBA show significant improvement over FBA, but iFBA and 13C-MFA offer highest accuracy.

Experimental Validation Protocol

A standard protocol for validating FBA-based predictions against 13C-MFA is outlined below.

Protocol: Cross-Validation of In Silico Flux Predictions with 13C-MFA

- Strain and Culture: Use a well-annotated model organism (e.g., E. coli MG1655) cultivated in a controlled bioreactor with defined minimal media (e.g., M9 with 0.5% w/v glucose).

- 13C-Tracer Experiment: Implement a parallel culture with a [1-13C]glucose tracer (typically 20% labeled, 80% unlabeled). Harvest cells during mid-exponential growth phase via rapid quenching.

- Metabolite Extraction & GC-MS: Extract intracellular metabolites. Derivatize (e.g., methoximation and silylation) and analyze proteinogenic amino acid fragments via Gas Chromatography-Mass Spectrometry (GC-MS).

- 13C-MFA Flux Calculation: Use software (e.g., INCA, IsoTool) to fit the network model to the measured Mass Isotopomer Distributions (MIDs), obtaining a statistically unique set of net and exchange fluxes.

- FBA Simulation: Run comparative simulations (Standard FBA, pFBA, ll-FBA) using a genome-scale model (e.g., iJO1366 for E. coli) constrained with the measured experimental uptake/secretion rates and growth rate.