FBA vs 13C-MFA: A Comprehensive Guide to Metabolic Flux Validation for Biomedical Research

This article provides a targeted comparison of Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C-MFA) as critical validation tools for metabolic models in drug development and biomedical research.

FBA vs 13C-MFA: A Comprehensive Guide to Metabolic Flux Validation for Biomedical Research

Abstract

This article provides a targeted comparison of Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C-MFA) as critical validation tools for metabolic models in drug development and biomedical research. We explore their foundational principles, methodological workflows, common optimization challenges, and comparative validation frameworks. Designed for researchers and scientists, this guide clarifies when and how to apply each method to enhance the accuracy and predictive power of computational models in studying disease metabolism and therapeutic targeting.

Decoding the Core: Foundational Principles of FBA and 13C-MFA

Metabolic network analysis is a cornerstone of systems biology, providing a quantitative framework to understand cellular physiology. Two principal computational methodologies are Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C-MFA). This guide objectively compares their performance, experimental validation, and applications within biomedical research.

Core Conceptual Comparison

FBA is a constraint-based modeling approach that predicts steady-state metabolic fluxes using an optimization principle (e.g., maximize biomass yield). It requires a genome-scale metabolic reconstruction and defines a solution space of possible fluxes without providing a unique solution. In contrast, 13C-MFA is an experimental-analytical hybrid method. It uses isotopic labeling patterns from 13C tracer experiments, integrated with metabolic network models, to compute a single, precise set of in vivo metabolic fluxes.

Quantitative Performance Comparison

Table 1: Methodological Comparison of FBA and 13C-MFA

| Feature | Flux Balance Analysis (FBA) | 13C Metabolic Flux Analysis (13C-MFA) |

|---|---|---|

| Primary Input | Stoichiometric model; Growth/uptake rates; Objective function. | 13C labeling data (MS/NMR); Extracellular fluxes. |

| Core Principle | Mathematical optimization within physico-chemical constraints. | Isotopic steady-state simulation & non-linear fitting. |

| Flux Resolution | Network-wide, but often lumped reactions; Underdetermined. | High resolution at central carbon metabolism; Determined. |

| Temporal Scale | Steady-state only. | Steady-state (typical) or instationary (advanced). |

| Key Output | Optimal flux distribution; Flux variability range. | Precise, absolute intracellular flux map. |

| Experimental Burden | Low (often uses published data). | High (requires dedicated tracer experiments). |

| Validation Basis | Consistency with growth phenotypes, gene knockouts. | Direct, empirical fit to isotopic labeling data. |

Table 2: Typical Performance Metrics from Validation Studies

| Metric | FBA Prediction vs. 13C-MFA Measurement | Notes / Experimental Context |

|---|---|---|

| Glycolytic Flux (mmol/gDW/h) | FBA: 8.5-12.0 (variable) | E. coli, aerobic, glucose-limited chemostat. 13C-MFA provides ground truth. |

| 13C-MFA: 10.2 ± 0.3 | ||

| PPF:EMP Split Ratio | FBA: Highly sensitive to objective function. | Pentose Phosphate Pathway vs. Glycolysis split. 13C-MFA quantifies this directly. |

| 13C-MFA: Precisely determined (e.g., 28:72) | ||

| ATP Turnover | FBA: Calculated from flux solution. | 13C-MFA can infer in vivo ATP demand through energy balance. |

| 13C-MFA: Experimentally inferred. | ||

| Prediction Accuracy | Moderate for central metabolism under defined conditions. | Accuracy decreases for secondary metabolism or without tight constraints. |

| High for core fluxes from experimental data. | Considered the gold standard for validation. |

Experimental Protocols for Key Validation Studies

Protocol 1: Core 13C-MFA Workflow for Flux Validation

- Experimental Design: Choose a 13C-labeled substrate (e.g., [1-13C]glucose). Cultivate cells in a controlled bioreactor at metabolic steady-state.

- Sampling & Quenching: Rapidly sample culture and quench metabolism (cold methanol/saline).

- Metabolite Extraction: Use a cold chloroform/methanol/water solvent system to extract intracellular metabolites.

- Derivatization & Analysis: Derivatize (e.g., TBDMS for amino acids) and analyze via GC-MS. Measure Mass Isotopomer Distributions (MIDs) of proteinogenic amino acids or pathway intermediates.

- Modeling & Fitting: Use a stoichiometric model of central metabolism. Simulate MIDs and iteratively fit net fluxes and exchange fluxes to minimize deviation between simulated and experimental MIDs via non-linear least squares regression (e.g., using INCA, OpenFLUX).

Protocol 2: Constraining FBA with 13C-MFA Data

- Flux Estimation: Perform 13C-MFA to obtain a set of high-confidence intracellular fluxes.

- Constraint Addition: Incorporate these measured fluxes as additional equality constraints into the FBA linear programming problem.

- Objective Testing: Test the accuracy of different biological objective functions (biomass maximization, ATP minimization) by comparing the resulting FBA predictions against the 13C-MFA-determined flux boundaries.

- Gap Analysis: Identify reactions where FBA predictions consistently deviate from MFA measurements, indicating potential gaps in model annotation or regulation.

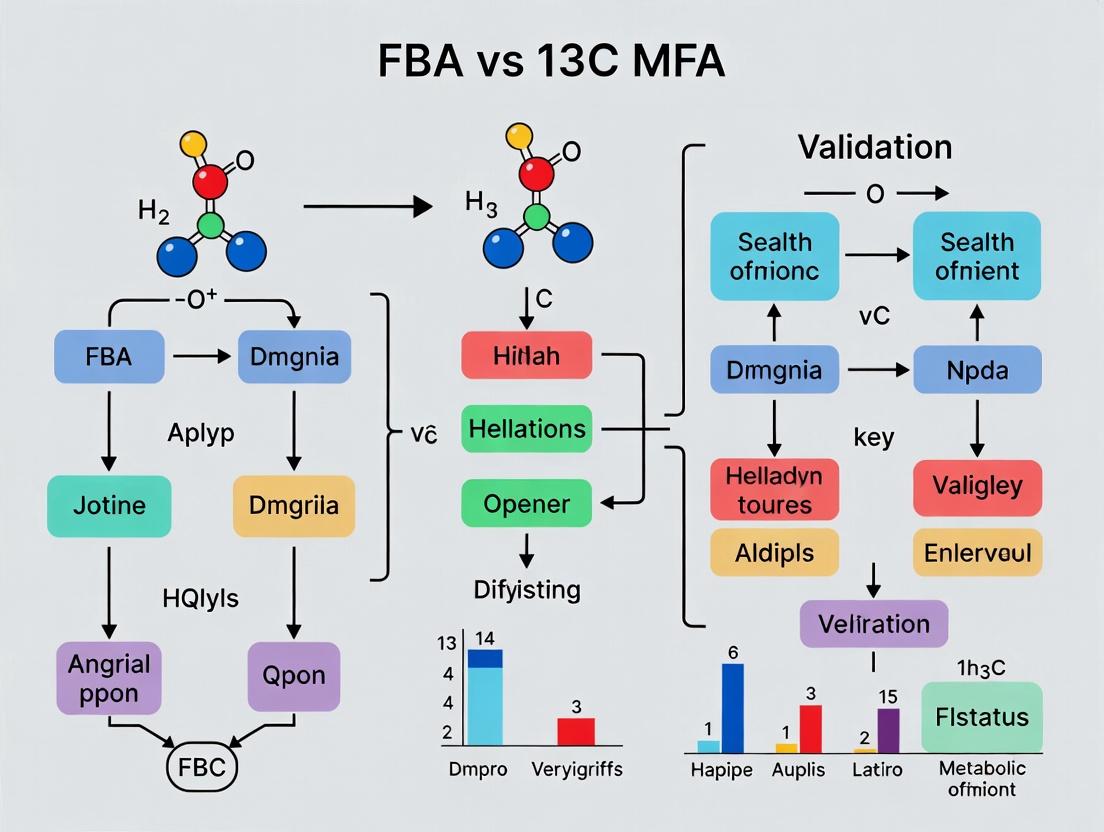

Visualizing the Workflow and Integration

Title: FBA and 13C-MFA Integration for Model Validation

Title: Core Metabolic Network with 13C Tracer Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 13C-MFA & FBA Validation

| Item | Function in Analysis | Example / Specification |

|---|---|---|

| 13C-Labeled Substrate | Tracer for determining metabolic pathway activity. | [1-13C]Glucose, [U-13C]Glutamine; >99% isotopic purity. |

| Defined Cell Culture Medium | Enables precise control of nutrient availability for steady-state. | Custom formulation without carbon sources interfering with tracer. |

| Bioreactor / Chemostat | Maintains cells at metabolic steady-state for reliable flux determination. | Systems with controlled pH, DO, temperature, and feed rates. |

| GC-MS System | Measures Mass Isotopomer Distributions (MIDs) of metabolites. | High sensitivity, electron impact ionization. |

| Metabolite Extraction Solvents | Quench metabolism and extract intracellular metabolites quantitatively. | Cold (-40°C) methanol/water/chloroform mixtures. |

| Derivatization Reagents | Volatilize metabolites for GC-MS analysis. | MTBSTFA, TBDMS, Methoxyamine hydrochloride. |

| FBA/MFA Software | Perform flux calculations, simulations, and statistical analysis. | COBRA Toolbox (FBA), INCA, OpenFLUX, IsoCor2 (13C-MFA). |

| Genome-Scale Model (GEM) | Scaffold for FBA predictions and 13C-MFA network definition. | Recon (human), iJO1366 (E. coli), consensus yeast models. |

This comparison guide evaluates two core methodologies for metabolic network analysis: Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C MFA). The analysis is framed within a thesis investigating validation methods for these approaches, critical for researchers and drug development professionals seeking accurate models of cellular metabolism. FBA relies on stoichiometric constraints and optimization, while 13C MFA utilizes isotopic steady-state data to infer intracellular fluxes.

Methodological Comparison: FBA vs. 13C MFA

Core Principles & Data Requirements

The fundamental distinction lies in their theoretical underpinnings. FBA uses the stoichiometric matrix of a metabolic network and linear programming to optimize for an objective (e.g., biomass maximization). It requires a genome-scale metabolic reconstruction but no experimental flux data. Conversely, 13C MFA fits a flux map to experimental data from isotopic labeling experiments, requiring detailed atom-transition models and measurements of isotopic enrichment at steady-state.

Performance Comparison Table

Table 1: Comparative Analysis of FBA and 13C MFA

| Aspect | Flux Balance Analysis (FBA) | 13C Metabolic Flux Analysis (13C MFA) |

|---|---|---|

| Theoretical Basis | Stoichiometry & Linear Programming Optimization | Isotopic Steady-State & Isotopomer Balancing |

| Primary Input | Genome-scale metabolic model, exchange fluxes | 13C-labeling data, extracellular fluxes, network model |

| Key Assumption | Steady-state mass balance; optimal cellular behavior | Metabolic & isotopic steady-state |

| Flux Resolution | Net fluxes; cannot resolve parallel pathways or reversibility | Gross fluxes; can resolve pathway reversibility and parallel routes |

| Validation Method | Comparison with gene essentiality or knockout data | Statistical goodness-of-fit to isotopic labeling data |

| Throughput | High (in silico) | Low (experimentally intensive) |

| Scope | Genome-scale (1000s of reactions) | Core metabolism (50-100 reactions) |

Experimental Protocols for Validation

Protocol 1: Generating 13C MFA Validation Data

- Culture & Tracer Experiment: Grow cells in a controlled bioreactor with a defined medium where a single carbon source (e.g., glucose) is replaced with its 13C-labeled counterpart (e.g., [1-13C]glucose).

- Achieve Isotopic Steady-State: Harvest cells only after isotopic labeling of intracellular metabolites has reached steady-state (typically 2-3 mass doublings).

- Quenching & Extraction: Rapidly quench metabolism (e.g., cold methanol), extract intracellular metabolites.

- Mass Spectrometry (MS) Analysis: Derivatize key metabolites (e.g., amino acids) and analyze via GC-MS or LC-MS to obtain mass isotopomer distributions (MIDs).

- Flux Estimation: Use software (e.g., INCA, 13CFLUX2) to iteratively fit the metabolic network model to the experimental MIDs and extracellular flux data, minimizing residual variance.

Protocol 2: Validating FBA Predictions Experimentally

- In Silico Simulation: Perform FBA on a condition-specific model to predict growth rates and essential genes/reactions.

- Experimental Cultivation: Cultivate wild-type and specific gene knockout strains in biological triplicate under the simulated conditions.

- Growth Phenotyping: Precisely measure growth rates (optical density) and substrate/product concentrations.

- Data Comparison: Statistically compare predicted vs. observed growth rates and essentiality calls. Use metrics like root mean square error (RMSE) or accuracy.

Visualizing Methodological Frameworks

Title: FBA Theoretical and Computational Workflow

Title: 13C MFA Experimental and Fitting Workflow

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for 13C MFA Validation Studies

| Item | Function |

|---|---|

| U-13C or 1-13C Labeled Glucose | Carbon tracer to follow metabolic pathways via isotopic enrichment. |

| Custom Chemically Defined Medium | Ensures precise control of nutrient sources for reproducible flux states. |

| Quenching Solution (e.g., -40°C 60% Methanol) | Instantly halts metabolic activity to capture in vivo metabolite levels. |

| Derivatization Reagents (e.g., MTBSTFA, Methoxyamine) | Prepares polar metabolites (amino acids, sugars) for GC-MS analysis by increasing volatility. |

| Internal Standards (13C/15N-labeled cell extract) | Allows for absolute quantification and corrects for MS instrument variability. |

| FBA Software (CobraPy, OptFlux) | Performs constraint-based modeling, simulation, and in silico strain optimization. |

| 13C MFA Software (INCA, 13CFLUX2) | Solves isotopomer balances and performs statistical flux estimation and validation. |

FBA and 13C MFA offer complementary insights, rooted in stoichiometry/optimization and isotopic steady-state, respectively. Validation remains paramount: FBA predictions require phenotypic data for confirmation, while 13C MFA is self-validating against the isotopic data but limited to core metabolism. Integrating both methods provides a powerful framework for robust metabolic model validation in therapeutic development.

Within the broader thesis investigating Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C MFA) as validation methods for each other, understanding their distinct and complementary applications is crucial. FBA, a constraint-based modeling approach, and 13C MFA, an experimental isotopomer analysis technique, are employed at different stages of metabolic research with varying objectives, data requirements, and outputs.

Comparative Analysis: FBA vs. 13C MFA

Table 1: Core Objectives and Typical Employment

| Aspect | Flux Balance Analysis (FBA) | 13C Metabolic Flux Analysis (13C MFA) |

|---|---|---|

| Primary Objective | To predict optimal metabolic flux distributions and phenotypic capabilities from a genome-scale metabolic model (GEM). | To experimentally determine in vivo metabolic reaction rates (fluxes) in a central metabolic network. |

| When Typically Employed | - For hypothesis generation and in silico prediction.- When experimental flux data is absent or limited.- For exploring genetic/perturbation scenarios (e.g., gene knockouts).- In the early stages of strain or pathway design (Systems Biology). | - For experimental validation of model predictions.- When high-precision, quantitative flux maps of central metabolism are required.- For understanding metabolic network physiology under defined conditions.- As a gold-standard validation step in metabolic engineering. |

| Key Input Requirements | 1. Genome-scale metabolic reconstruction.2. A defined objective function (e.g., maximize growth).3. Physico-chemical constraints (e.g., reaction stoichiometry, bounds). | 1. 13C-labeled substrate (e.g., [1-13C]glucose).2. Measured extracellular uptake/secretion rates.3. Mass isotopomer distribution (MID) data from intracellular metabolites (via GC-MS or LC-MS). |

| Typical Output | A predicted flux distribution that optimizes the objective function. Provides a range of possible fluxes. | A statistically fitted, unique set of net fluxes and bidirectional exchange fluxes for the core network. |

| Major Strength | Scalability to full genome; enables exploration of all possible metabolic states. | Provides accurate, quantitative, and physiologically relevant empirical flux data. |

| Major Limitation | Predictions are sensitive to the objective function and constraints; may not reflect real physiology. | Experimentally intensive; limited to central carbon metabolism due to analytical complexity. |

Table 2: Supporting Experimental Data from Comparative Studies

| Study Focus | FBA Prediction | 13C MFA Result | Key Insight on Method Employment |

|---|---|---|---|

| E. coli under Oxygen Limitation | Predicted high flux through anaerobic pathways (mixed-acid fermentation). | Quantified significant flux re-routing to succinate and lactate. | 13C MFA validated the general FBA prediction but provided exact quantitative redistributions, crucial for engineering. |

| S. cerevisiae on Different Carbon Sources | Predicted changes in PPP and TCA cycle activity between glucose and galactose. | Measured precise flux split ratios at key branch points (e.g., G6P). | FBA identified which pathways were active; 13C MFA was required to measure to what degree. |

| Cancer Cell Metabolism (HeLa) | FBA of consensus GEM predicted dependency on glycolysis and glutaminolysis. | Confirmed high glycolytic flux and revealed context-dependent TCA cycle activity. | FBA provides a theoretical framework; 13C MFA delivers the context-specific experimental ground truth for validation. |

Experimental Protocols

Detailed Protocol for 13C MFA

- Tracer Experiment: Cultivate cells in a controlled bioreactor with a defined medium containing a precisely chosen 13C-labeled carbon source (e.g., [1-13C]glucose). Achieve metabolic and isotopic steady-state.

- Metabolite Quenching & Extraction: Rapidly quench metabolism (e.g., cold methanol). Extract intracellular metabolites from cell pellets.

- Derivatization & MS Analysis: Derivatize polar metabolites (e.g., amino acids, organic acids). Analyze via Gas Chromatography-Mass Spectrometry (GC-MS) to obtain Mass Isotopomer Distributions (MIDs).

- Flux Calculation: Use a stoichiometric model of central metabolism. Input:

- Network stoichiometry.

- Measured extracellular fluxes (substrate uptake, product secretion, growth rate).

- Measured MIDs from step 3. Employ an iterative least-squares algorithm (e.g., in software like INCA or 13C-FLUX2) to find the flux set that best fits the experimental MID data, providing statistically confident intervals.

Detailed Protocol for FBA Validation Using 13C MFA Data

- Model Curation: Refine the GEM based on genomic and bibliomic data for the specific organism/cell line.

- Constraint Definition: Apply constraints from the 13C MFA experimental condition:

- Set substrate uptake rates to measured values.

- Constrain by-product secretion rates.

- Set growth rate to the measured value.

- Flux Prediction: Perform FBA (e.g., using COBRApy) with an appropriate objective function (often biomass maximization) to obtain a predicted flux distribution.

- Comparison & Gap Analysis: Statistically compare FBA-predicted fluxes for core reactions against the 13C MFA-determined fluxes. Identify reactions with significant discrepancies to guide model improvement (e.g., adding regulatory constraints).

Visualizations

Title: Workflow for FBA Prediction and 13C MFA Validation

Title: Decision Logic for Employing FBA or 13C MFA

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for FBA and 13C MFA Research

| Item / Reagent | Function in Research | Typical Use Case |

|---|---|---|

| Genome-Scale Metabolic Reconstruction (e.g., from BiGG Models) | Provides the stoichiometric matrix of all known metabolic reactions for an organism. | Essential starting point for constructing an FBA model. |

| COBRA Toolbox (MATLAB) or COBRApy (Python) | Software suites for performing constraint-based modeling, including FBA. | Used to set up, constrain, solve, and analyze FBA models. |

| U-13C or Position-Specific 13C-Labeled Substrate (e.g., [U-13C]glucose) | Tracer that introduces measurable isotopic labels into metabolic networks. | The fundamental reagent for any 13C MFA experiment to generate isotopomer data. |

| Quenching Solution (e.g., Cold Methanol -40°C) | Rapidly halts cellular metabolism to capture an accurate snapshot of intracellular metabolite levels. | Critical first step in 13C MFA sample preparation to ensure data reliability. |

| Derivatization Reagents (e.g., MSTFA for GC-MS) | Chemically modify polar metabolites to make them volatile and suitable for GC-MS analysis. | Prepares extracted metabolites for mass spectrometric detection of mass isotopomers. |

| Isotope Modeling Software (e.g., INCA, 13C-FLUX2) | Platforms for designing tracer experiments, importing MS data, and fitting metabolic fluxes. | Used to convert raw MS isotopomer data into a quantitative flux map via computational fitting. |

| High-Resolution Mass Spectrometer (GC-MS or LC-MS) | Instrument to separate metabolites and precisely measure the abundance of their different mass isotopomers. | Generates the primary experimental data (MIDs) for 13C MFA flux calculation. |

Within the ongoing research thesis comparing Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C MFA) validation methods, understanding the foundational inputs and resulting outputs of each approach is critical. This guide objectively compares their performance in constructing and validating genome-scale metabolic models, highlighting constraints and flux map accuracy.

Core Methodological Comparison: Inputs and Outputs

The following table summarizes the essential inputs, constraints, and outputs that define and differentiate FBA and 13C MFA.

| Aspect | Flux Balance Analysis (FBA) | 13C Metabolic Flux Analysis (13C MFA) |

|---|---|---|

| Primary Inputs | 1. Genome-scale metabolic reconstruction (SBML). 2. Objective function (e.g., maximize biomass). 3. Environmental constraints (e.g., O2, glucose uptake). 4. Steady-state assumption. | 1. Network model (central metabolism). 2. 13C-labeling data (e.g., from GC-MS). 3. Extracellular uptake/secretion rates. 4. Isotopic steady-state assumption. |

| Key Constraints | Linear: Mass-balance, reaction capacity (vmin, vmax). | Non-linear: Mass-balance, isotopomer balance. |

| Primary Output | A single flux distribution optimizing the objective. | A statistically fitted, experimentally validated flux map. |

| Validation Basis | Predictive consistency with in silico knockouts/growth. | Direct experimental agreement with isotopic labeling patterns. |

| Scope & Scale | Genome-scale (1000s of reactions). | Central metabolism (50-100 reactions). |

| Temporal Resolution | Pseudo-steady-state (hours). | Steady-state (hours) or instationary (minutes). |

Experimental Protocol: Integrated Validation Workflow

A robust validation protocol for metabolic models often integrates both techniques.

Title: Sequential FBA Prediction and 13C MFA Validation.

Method:

- Model Curation: Construct a genome-scale metabolic model (GEM) from genomic data and literature (e.g., in COBRApy).

- FBA Simulation: Apply environmental conditions (e.g., glucose-limited aerobic culture) and run FBA to predict a genome-scale flux distribution and growth rate.

- Cultivation & Sampling: Grow the organism (e.g., E. coli, CHO cells) in a controlled bioreactor under the same defined conditions. Feed 13C-labeled substrate (e.g., [1-13C]glucose).

- Metabolite Extraction & Measurement: Harvest cells at metabolic steady-state. Quench metabolism, extract intracellular metabolites from central pathways. Derivatize and analyze via GC-MS or LC-MS to obtain mass isotopomer distributions (MIDs).

- 13C MFA Computational Fit: Use software (e.g., INCA, OpenFLUX) to fit fluxes in the core metabolic network to the experimental MIDs and extracellular rates. Obtain a statistically best-fit flux map with confidence intervals.

- Comparison & Validation: Compare the fluxes in the core network predicted by FBA (Step 2) with the experimentally determined fluxes from 13C MFA (Step 5). Discrepancies indicate gaps in model constraints or biology.

Diagram: Integrated Model Validation Workflow

Quantitative Performance Comparison: Prediction vs. Measurement

Recent studies comparing FBA predictions against 13C MFA measurements in E. coli and S. cerevisiae under various conditions reveal systematic patterns.

| Condition | Metric | FBA Prediction | 13C MFA Measurement | Discrepancy & Implication |

|---|---|---|---|---|

| Aerobic, Glucose-Limited | Growth Rate (h⁻¹) | 0.42 | 0.39 ± 0.02 | Good agreement; objective function valid. |

| PPP Flux (Glycolysis %) | 28% | 65% ± 5% | Large error; FBA misses regulatory/redox constraints. | |

| Anaerobic, Glucose | TCA Cycle Flux | Near Zero | Significant (15%) | FBA misses cyclic topology for biosynthesis. |

| Glutamine as Substrate | Entner-Doudoroff Flux | 0 | 85% ± 8% | Gaps in model annotation/pathway knowledge. |

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in FBA/13C MFA Research |

|---|---|

| Uniformly 13C-Labeled Substrates (e.g., [U-13C]glucose) | Essential tracer for 13C MFA; enables mapping of complete labeling patterns in central metabolism. |

| Positional Tracers (e.g., [1-13C]glutamine) | Used for probing specific pathway activities and resolving parallel route fluxes (e.g., anaplerosis). |

| Defined Culture Media Kits | Provide reproducible, chemically defined environments critical for applying accurate constraints in FBA and 13C MFA. |

| Enzymatic Assay Kits for Extracellular Rates | Measure substrate uptake and byproduct secretion rates, key quantitative inputs for both FBA and MFA. |

| Derivatization Reagents for GC-MS (e.g., MSTFA) | Prepare polar metabolites (amino acids, sugars) for gas chromatography separation and mass spectrometry analysis. |

| COBRA Toolbox (MATLAB) / COBRApy | Standard software suites for building, constraining, and running FBA simulations on genome-scale models. |

| INCA or OpenFLUX Software | Specialized platforms for designing 13C MFA models, fitting fluxes to labeling data, and performing statistical analysis. |

| Quenching Solution (e.g., -40°C Methanol) | Rapidly halts metabolic activity during sampling to preserve in vivo flux states for 13C MFA. |

Within the research on Flux Balance Analysis (FBA) validation via 13C-Metabolic Flux Analysis (13C MFA), a fundamental tension exists between constraint-based, in silico prediction and direct experimental measurement. This guide objectively compares these paradigms, providing experimental data and protocols to inform researchers and drug development professionals.

Comparative Performance Analysis

Table 1: Core Methodological Distinctions

| Feature | Constraint-Based Prediction (FBA) | Experimental Measurement (13C MFA) |

|---|---|---|

| Primary Basis | Genome-scale metabolic models & optimization (e.g., max biomass) | Isotopic steady-state & mass isotopomer distribution (MID) measurement |

| Temporal Resolution | Steady-state only | Steady-state; recent advances in instationary MFA (INST-MFA) |

| Flux Network Scope | Genome-scale (1000s of reactions) | Central carbon metabolism (50-100 reactions) |

| Key Inputs | Stoichiometry, exchange bounds, objective function | 13C-labeling pattern, extracellular fluxes, network model |

| Key Output | Predicted flux distribution (relative, in mmol/gDW/h) | Measured in vivo flux distribution (absolute, in mmol/gDW/h) |

| Validation Method | Requires experimental (e.g., 13C MFA) validation | Serves as empirical ground truth for validation |

| Typical Throughput | High (computational) | Low (experimentally intensive) |

| Major Uncertainty Source | Model gaps/errors, objective function choice | Measurement noise, isotopic labeling design, model redundancies |

Table 2: Quantitative Comparison of FBA Prediction vs. 13C MFA Measurement in E. coli (Glucose Minimal Media, Aerobic)

| Metabolic Flux (reaction) | FBA Prediction (mmol/gDW/h) | 13C MFA Measurement (mmol/gDW/h) | Absolute Deviation | % Error |

|---|---|---|---|---|

| Glycolysis (GLC → PYR) | 10.5 | 8.9 ± 0.3 | +1.6 | +18% |

| Pentose Phosphate Pathway (G6P shunt) | 1.2 | 2.1 ± 0.2 | -0.9 | -43% |

| TCA Cycle (OXPHOS) | 8.7 | 7.5 ± 0.4 | +1.2 | +16% |

| Anaplerotic Flux (PYR → OAA) | 1.8 | 2.5 ± 0.2 | -0.7 | -28% |

| Biomass Synthesis | 0.45 (objective) | 0.42 ± 0.02 | +0.03 | +7% |

Data synthesized from recent studies (2023-2024) on *E. coli BW25113 under chemostat conditions (μ=0.4 h⁻¹). FBA used iJO1366 model with parsimonious FBA (pFBA).*

Detailed Experimental Protocols

Protocol 1: Core 13C MFA Workflow for Experimental Flux Measurement

- Tracer Experiment: Cultivate cells in a controlled bioreactor with a defined 13C-labeled substrate (e.g., [1-13C]glucose or [U-13C]glucose). Achieve metabolic and isotopic steady-state (typically 5-7 generations).

- Metabolite Quenching & Extraction: Rapidly quench metabolism (e.g., cold methanol/saline). Perform intracellular metabolite extraction.

- Derivatization & Analysis: Derivatize key metabolites (e.g., amino acids from protein hydrolysate, intracellular intermediates). Analyze via Gas Chromatography-Mass Spectrometry (GC-MS) or Nuclear Magnetic Resonance (NMR) to obtain Mass Isotopomer Distributions (MIDs).

- Flux Calculation: Input MIDs, extracellular flux rates, and a metabolic network model into a computational software (e.g., INCA, 13CFLUX2). Use an iterative least-squares algorithm to find the flux map that best fits the experimental MID data, providing statistical confidence intervals.

Protocol 2:In SilicoFBA Workflow for Flux Prediction

- Model Curation: Select a genome-scale metabolic reconstruction (GEM) relevant to the organism (e.g., Recon3D for human, iML1515 for E. coli).

- Constraint Definition: Apply context-specific constraints:

- Exchange Bounds: Based on measured substrate uptake/secretion rates.

- Gene Expression: Optionally integrate transcriptomic data to create tissue- or condition-specific models (e.g., via GIMME or iMAT).

- Thermodynamic: Apply to reduce solution space.

- Objective Function: Define a biologically relevant objective (e.g., maximize biomass reaction for microbes, maximize ATP yield for certain tissues).

- Optimization & Solution: Solve the linear programming problem (maximize Z = cᵀv subject to S·v = 0 and lb ≤ v ≤ ub). Extract the optimal flux distribution. Techniques like Flux Variability Analysis (FVA) assess the solution space range.

Visualization of Workflows and Relationships

Title: FBA Prediction vs 13C MFA Measurement Workflow Comparison

Title: Thesis Context for Prediction vs Measurement Distinction

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagents and Solutions for 13C MFA & FBA Validation Studies

| Item | Function/Description | Example Product/Catalog |

|---|---|---|

| 13C-Labeled Substrates | Tracers for metabolic flux experiments; define labeling pattern. | [1-13C]Glucose, [U-13C]Glucose (Cambridge Isotope Labs, CLM-1396) |

| Quenching Solution | Instantly halts metabolic activity to capture in vivo state. | Cold 60% Aqueous Methanol (-40°C to -50°C) |

| Derivatization Reagents | Chemically modify metabolites for volatility in GC-MS analysis. | N-Methyl-N-(tert-butyldimethylsilyl)trifluoroacetamide (MTBSTFA) |

| Internal Standards (13C) | Correct for instrument variability in MS quantification. | U-13C-labeled cell extract or specific amino acid mixes. |

| Cell Culture Media (Custom) | Chemically defined, minimal media for precise flux control. | M9 Minimal Salts, supplemented with trace elements & labeled carbon source. |

| Genome-Scale Model (GEM) | Digital representation of metabolism for FBA. | Human: Recon3D; E. coli: iML1515; S. cerevisiae: Yeast8 (from public repositories) |

| FBA/MFA Software | Computational platforms for flux calculation. | FBA: COBRA Toolbox (MATLAB), 13C MFA: INCA (MATLAB), 13CFLUX2 (Web) |

| GC-MS System | Instrument for measuring mass isotopomer distributions (MIDs). | Agilent 8890 GC / 5977B MS with DB-5MS column. |

From Theory to Bench: Step-by-Step Workflows and Research Applications

This comparison guide, situated within a broader thesis investigating validation methods for Flux Balance Analysis (FBA) versus 13C Metabolic Flux Analysis (13C MFA), examines the core components of constraint-based metabolic modeling. We objectively compare the performance of different FBA objective functions and reconstruction databases, supported by experimental validation data.

Comparison of Genome-Scale Reconstruction Databases

The foundation of any FBA model is a high-quality, organism-specific genome-scale reconstruction (GEM). The following table compares key databases and resources used for building GEMs.

Table 1: Comparison of Major Genome-Scale Reconstruction Resources

| Resource / Database | Primary Organisms | Key Features | Citation Count (approx.) | Curated Reaction Count (E. coli core) |

|---|---|---|---|---|

| ModelSEED / KBase | Prokaryotes, Eukaryotes | Automated pipeline, high-throughput, integrated with KBase platform | 1,200+ | Not Applicable (platform) |

| BiGG Models | Human, E. coli, S. cerevisiae | Highly curated, standardized namespace, biochemical accuracy | 2,800+ | ~95 (Human1) |

| AGORA (VMH) | >800 Gut Microbes | Community modeling focus, resource allocation data | 850+ | Varies by organism |

| CarveMe | Prokaryotes | Automated, generates condition-specific models | 300+ | Generates from genome |

| EcoCyc | E. coli | Deeply annotated, pathway-centric, literature-based | 4,500+ | 2,044 (iML1515) |

Data compiled from recent literature and resource websites (2023-2024). Citation counts are approximate from Google Scholar.

Objective Functions: Performance Comparison in Predictive Accuracy

The objective function mathematically defines the biological goal of the modeled system. Predictive accuracy varies significantly based on the chosen objective. Validation is often performed against 13C MFA or experimental growth rate data.

Table 2: Performance of Common FBA Objective Functions vs. 13C MFA Validation

| Objective Function | Typical Use Case | Predictive Accuracy (vs. 13C MFA)* | Key Limitation | Best-Suited Organism Type |

|---|---|---|---|---|

| Biomass Maximization | Standard growth prediction | High (R² ~0.85-0.92 for growth rates) | Assumes evolution optimizes growth; fails in non-growth conditions | Prokaryotes in exponential phase |

| ATP Maximization | Energy production studies | Moderate (R² ~0.65-0.75 for energy flux) | Can predict unrealistic futile cycles | Mitochondria, energy metabolism |

| MOMA / ROOM | Knock-out simulation | High (R² >0.9 for flux prediction in knockouts) | Computationally intensive; requires reference state | Engineered strains, mutants |

| MCC (Minimum Carbon Concentration) | Nutrient efficiency | Variable (R² ~0.7-0.8 for substrate uptake) | Sensitive to network boundaries | Nutrient-limited environments |

| Product Synthesis Maximization | Metabolic engineering | Moderate-High for target flux, Low for global state | Over-predicts yield if regulatory constraints missing | Industrial chassis organisms |

Accuracy metrics are generalized from published comparative studies (e.g., *Metab. Eng., 2021) comparing FBA flux predictions to 13C MFA central carbon fluxes in E. coli and S. cerevisiae under defined conditions.*

Experimental Protocols for FBA Validation

A critical component of the FBA vs. 13C MFA thesis is the validation of FBA predictions. Below is a standard protocol for generating experimental data to constrain and validate an FBA model.

Protocol 1: Generating Experimental Data for FBA Constraints and Validation

- Culture Conditions: Grow organism (e.g., E. coli K-12 MG1655) in a defined minimal medium (e.g., M9 with 2 g/L glucose) in a controlled bioreactor (triplicate runs).

- Quantitative Measurements:

- Uptake/Secretion Rates: Measure extracellular metabolite concentrations (glucose, organic acids, amino acids) via HPLC over exponential phase. Calculate specific uptake/secretion rates (mmol/gDW/h).

- Growth Rate: Calculate specific growth rate (μ, h⁻¹) from OD₆₀₀ measurements correlated to dry cell weight.

- Oxygen Uptake Rate (OUR) & CO₂ Production Rate (CPR): Measure via off-gas analysis.

- 13C MFA for Core Validation: Implement parallel cultures with 13C-labeled glucose (e.g., [1-13C]glucose). Harvest cells at mid-exponential phase. Derive intracellular flux maps via GC-MS analysis of proteinogenic amino acid labeling patterns and computational fitting (using software like INCA or 13CFLUX2).

- Data Integration: Use measured uptake/secretion rates and growth rate as constraints in the FBA model (lower/upper bounds). Compare the FBA-predicted central carbon fluxes and growth rate to the 13C MFA-derived fluxes and the experimentally measured growth rate.

Visualizing the FBA Workflow and Validation

Diagram Title: FBA Model Building and 13C MFA Validation Cycle

The Scientist's Toolkit: Research Reagent & Software Solutions

Table 3: Essential Resources for FBA Modeling and Validation Experiments

| Item / Resource | Category | Function / Application |

|---|---|---|

| Defined Minimal Media (e.g., M9, CDM) | Reagent | Provides controlled nutrient environment for consistent experimental and simulation conditions. |

| 13C-Labeled Substrates (e.g., [1-13C]Glucose) | Reagent | Enables 13C Metabolic Flux Analysis to measure in vivo intracellular reaction rates for validation. |

| CobraPy / MATLAB COBRA Toolbox | Software | Primary programming environments for building, simulating, and analyzing constraint-based models. |

| INCA or 13CFLUX2 | Software | Computationally efficient software for designing 13C tracing experiments and estimating metabolic fluxes from MS data. |

| BiGG Database API | Database | Access curated, standardized biochemical reaction and metabolite data for manual model refinement. |

| GC-MS or LC-MS System | Instrument | Quantifies isotopic labeling patterns in metabolites for 13C MFA and extracellular rates for FBA constraints. |

| KBase (kb.nmsu.edu) | Platform | Integrated cloud platform for automated reconstruction, simulation, and community model sharing. |

The construction of a predictive FBA model hinges on the interplay between curated genome-scale reconstructions, biologically relevant objective functions, and accurately measured constraints. While biomass maximization performs robustly for predicting growth phenotypes, its accuracy diminishes for engineering or non-proliferative scenarios, highlighting the need for context-specific objectives. Direct comparison to 13C MFA remains the gold standard for validating intracellular flux predictions, driving iterative model refinement. This comparative analysis underscores that the choice of reconstruction source and objective function must be strategically aligned with the biological question and validated with appropriate experimental data, a core tenet of the ongoing FBA vs. 13C MFA methodological discourse.

Within the ongoing research validation framework comparing Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C-MFA), the precise execution of 13C-MFA is critical. FBA provides a genome-scale, constraint-based prediction, but 13C-MFA delivers an experimentally validated, quantitative snapshot of in vivo metabolic fluxes. This guide compares core methodologies and tools essential for robust 13C-MFA.

Tracer Design: [1-2-13C]Glucose vs. [U-13C]Glucose

The choice of tracer dictates the measurable metabolic information and computational resolvability of fluxes.

Table 1: Comparison of Common Glucose Tracers in 13C-MFA

| Tracer Compound | Key Advantage | Key Limitation | Ideal for Resolving |

|---|---|---|---|

| [1-2-13C]Glucose | Generates distinct labeling in glycolysis & PPP derivatives. Lower cost. | Less informative for TCA cycle symmetries. | Glycolytic vs. pentose phosphate pathway flux, anaplerotic reactions. |

| [U-13C]Glucose (Uniformly Labeled) | Rich information content across entire network, including TCA cycle. | Higher cost. More complex isotopic labeling patterns. | Complete central carbon metabolism, especially mitochondrial fluxes. |

Experimental Protocol (Tracer Preparation):

- Solution Preparation: Prepare a base culture medium lacking natural carbon sources (e.g., glucose).

- Tracer Addition: Aseptically dissolve the chosen 13C-labeled glucose (e.g., 99% atom purity) in the medium to the desired concentration (typically 5-20 mM for mammalian cells).

- Sterilization: Filter-sterilize (0.22 µm) the complete tracer medium prior to use.

Culturing Systems: Batch vs. Chemostat

The culturing method controls the metabolic steady-state, a prerequisite for standard 13C-MFA.

Table 2: Comparison of Culturing Methods for 13C-MFA

| Culturing Method | Metabolic State | Experimental Complexity | Data Quality for MFA |

|---|---|---|---|

| Batch Culture | Quasi-steady-state only during mid-exponential phase. Simple and common. | Medium. Requires precise timing for sampling during balanced growth. | Can be high if sampled correctly, but extracellular rates change over time. |

| Chemostat (Continuous) Culture | Defined, steady-state. Constant extracellular metabolite concentrations. | High. Requires specialized equipment and longer stabilization time. | Excellent. Provides true metabolic and isotopic steady-state. |

Experimental Protocol (Steady-State Culturing & Quenching):

- Inoculation & Growth: Inoculate cells into the tracer medium at a low seeding density.

- Steady-State Achievement: For batch, monitor growth and harvest cells precisely during mid-exponential phase (e.g., OD600 ~0.6 for bacteria). For chemostat, operate at a fixed dilution rate for >5 residence times before sampling.

- Metabolic Quenching: Rapidly transfer culture (1 mL) into -40°C methanol:water (60:40, v/v) solution to instantly halt metabolism. Pellet cells at -20°C.

- Extraction: Use cold chloroform/methanol/water for biphasic extraction of intracellular metabolites. Dry the aqueous (polar) phase under nitrogen gas.

Measurement: GC-MS vs. LC-MS vs. NMR

The analytical platform determines the type and quality of isotopic labeling data.

Table 3: Comparison of Analytical Platforms for 13C-MFA

| Platform | Measured Data | Throughput | Sensitivity | Key Limitation |

|---|---|---|---|---|

| GC-MS (after derivatization) | Mass Isotopomer Distributions (MIDs) of fragments. | High | Excellent (femto-picomole) | Requires derivatization; fragment information can be complex. |

| LC-HRMS (High-Resolution MS) | Intact metabolite MIDs; can separate isomers. | High | Excellent | Data complexity; ion suppression can affect quantitation. |

| 2D NMR (e.g., 1H-13C HSQC) | Positional 13C-enrichment & isotopomer abundances. | Low | Lower (nanomole) | Low throughput; requires larger sample amounts. |

Experimental Protocol (GC-MS Sample Preparation & Run):

- Derivatization: Redissolve dried polar extract in 20 µL methoxyamine hydrochloride (20 mg/mL in pyridine), incubate 90 min at 37°C. Then add 80 µL MSTFA (N-Methyl-N-(trimethylsilyl)trifluoroacetamide), incubate 30 min at 37°C.

- GC-MS Analysis: Inject 1 µL in splitless mode. Use a DB-5MS column. Oven program: 60°C to 300°C at 10°C/min. Operate MS in electron impact (EI) mode, scanning m/z 70-600.

- Data Processing: Integrate chromatographic peaks. Correct MIDs for natural isotope abundances using software like IsoCor.

Computational Fitting: Software Platforms

Software performs the non-linear regression of the metabolic network model to the isotopic data.

Table 4: Comparison of 13C-MFA Software

| Software | Primary Method | User Interface | Key Feature | Best For |

|---|---|---|---|---|

| INCA | Elementary Metabolite Units (EMU) algorithm, non-linear least squares. | MATLAB-based GUI. | Comprehensive modeling, confidence interval analysis. | Detailed, high-resolution flux maps in central metabolism. |

| 13CFLUX2 | Net/Cumomer balancing, non-linear least squares. | Standalone GUI & command line. | Efficient large-scale network analysis. | High-throughput or large-scale metabolic networks. |

| OpenFlux | EMU-based. Open source. | Web-based interface. | Accessibility, community development. | Educational use and open-source pipeline integration. |

Experimental Protocol (Computational Flux Estimation with INCA):

- Model Definition: Construct a stoichiometric model of central metabolism in INCA, specifying atom transitions for each reaction.

- Data Input: Input measured MIDs for key metabolites (e.g., alanine, lactate, glutamate, serine) and net extracellular fluxes (e.g., glucose uptake, lactate secretion).

- Flux Estimation: Run the non-linear least-squares fitting to minimize the difference between simulated and measured MIDs.

- Statistical Analysis: Perform chi-square statistical test for goodness-of-fit. Use Monte Carlo simulations to estimate 95% confidence intervals for each resolved flux.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in 13C-MFA |

|---|---|

| 13C-Labeled Glucose Tracers | The isotopic probe that introduces measurable labels into metabolism. |

| Custom Carbon-Free Base Medium | Ensures the tracer is the sole carbon source, defining the labeling input. |

| Methanol:Water Quenching Solution | Instantly halts cellular metabolism to capture a true isotopic snapshot. |

| Chloroform (HPLC grade) | Used in biphasic extraction to separate lipids from polar metabolites. |

| Methoxyamine Hydrochloride & MSTFA | Derivatizing agents for GC-MS; protect carbonyl groups and add volatility. |

| Isotopic Standard Mix | For correcting instrument drift and natural isotope abundance in MS data. |

| Flux Estimation Software (e.g., INCA) | The computational engine for translating labeling data into flux values. |

Visualizations

Title: 13C-MFA Experimental & Computational Workflow

Title: FBA Prediction vs 13C-MFA Validation Context

Within the ongoing research paradigm comparing Flux Balance Analysis (FBA) validation methods with 13C Metabolic Flux Analysis (13C MFA), a critical application of FBA lies in its predictive power for hypothesis generation and in-silico knockout studies. This guide compares the performance of constraint-based FBA modeling against alternative methods like 13C MFA and kinetic modeling in this specific context, supported by experimental data.

Performance Comparison: FBA vs. Alternatives for Knockout Prediction

The table below summarizes the core characteristics of FBA when used for in-silico knockout simulations, compared to other flux estimation methods.

Table 1: Comparison of Methods for In-Silico Knockout Studies

| Aspect | Flux Balance Analysis (FBA) | 13C Metabolic Flux Analysis (13C MFA) | Kinetic Modeling |

|---|---|---|---|

| Primary Use in Knockouts | Genome-scale prediction of growth, essentiality, and flux redistribution. | Experimental validation of in vivo flux changes post-knockout. | Detailed dynamic prediction of metabolite concentration changes. |

| Throughput | High (can simulate all single-gene knockouts rapidly). | Low (labor-intensive, requires isotopic tracing for each condition). | Very Low (requires extensive parameterization per condition). |

| Requirement for Experimental Data | Low (requires a genome-scale model and growth objective). | High (requires precise mass spectrometry data for each knockout). | Very High (requires kinetic constants and concentration data). |

| Quantitative Accuracy | Moderate (good at predicting growth/no-growth; less accurate for exact flux magnitudes). | High (provides quantitative, validated flux maps). | Potentially High (if parameters are accurately known). |

| Key Strength for Hypothesis Gen. | Systems-level perspective, identification of synthetic lethality and metabolic bypasses. | Ground-truth validation for central carbon metabolism fluxes. | Mechanistic insight into regulatory responses and dynamics. |

| Key Limitation | Relies on optimality assumption; may miss regulatory constraints. | Limited to central metabolism; not genome-scale. | Models are small-scale and difficult to parameterize accurately. |

Supporting data from a seminal E. coli study illustrates FBA's predictive power: Table 2: Validation of FBA Predictions for Single-Gene Knockouts in E. coli (Glucose Minimal Media)

| Gene Knockout | FBA Prediction (Growth Rate % of WT) | Experimental Growth (Growth Rate % of WT) | Essentiality Prediction Correct? |

|---|---|---|---|

| pfkA (Glycolysis) | 100% (Non-essential) | 98% | Yes |

| pgi | 0% (Essential) | 0% | Yes |

| pykF | 100% (Non-essential) | 95% | Yes |

| zwf (PPP) | 100% (Non-essential) | 102% | Yes |

| sdhC (TCA) | 0% (Essential) | 0% | Yes |

Data adapted from key validation studies comparing FBA predictions to experimental growth data.

Experimental Protocols

Protocol 1: Standard FBA In-Silico Gene Knockout Simulation

- Model Curation: Obtain a genome-scale metabolic reconstruction (e.g., from BiGG or MetaCyc).

- Knockout Implementation: In silico, set the upper and lower bounds of all reactions catalyzed by the target gene product to zero.

- Simulation: Perform FBA by solving the linear programming problem: Maximize Z = cᵀv (where Z is often the biomass reaction), subject to S·v = 0 and lb ≤ v ≤ ub (modified in step 2).

- Analysis: Compare the optimal objective function (e.g., growth rate) to the wild-type simulation. A zero or significantly reduced flux indicates an essential or growth-impairing gene.

- Hypothesis Generation: For non-essential knockouts, analyze the alternative flux distribution to predict compensatory pathways.

Protocol 2: 13C MFA for Experimental Validation of In-Silico Knockouts

- Strain Creation: Construct the gene knockout strain predicted in silico.

- Isotope Tracer Experiment: Grow the wild-type and knockout strains in a controlled bioreactor with a 13C-labeled carbon source (e.g., [1-13C]glucose).

- Sampling & Metabolite Extraction: Harvest cells at mid-exponential phase and quench metabolism rapidly. Extract intracellular metabolites.

- Mass Spectrometry: Analyze proteinogenic amino acids or central metabolites via GC-MS or LC-MS to measure 13C labeling patterns (mass isotopomer distributions).

- Flux Estimation: Use software (e.g., INCA, 13CFLUX2) to fit a metabolic network model to the labeling data, calculating the in vivo flux distribution for the knockout.

- Validation: Compare the experimental 13C MFA flux map to the FBA-predicted flux redistribution for the same knockout, identifying areas of agreement and discrepancy to refine the FBA model.

Visualization of Workflows

FBA and 13C MFA Workflow for Knockout Studies

Logic of Hypothesis Generation from FBA Knockouts

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBA-Driven Knockout Studies

| Item / Solution | Function in Research |

|---|---|

| Genome-Scale Model (e.g., Recon, iML1515) | The core mathematical representation of metabolism for in-silico simulations. |

| Constraint-Based Modeling Software (COBRApy, RAVEN Toolbox) | Platform to implement FBA, perform knockouts, and analyze flux solutions. |

| 13C-Labeled Substrates (e.g., [U-13C]Glucose) | Critical tracers for experimental flux validation via 13C MFA in knockout strains. |

| GC-MS or LC-MS System | Instrumentation required to measure mass isotopomer distributions from 13C experiments. |

| 13C MFA Software (INCA, 13CFLUX2) | Used to statistically fit metabolic network models to MS data and compute validated flux maps. |

| CRISPR/Cas9 or Lambda Red Kit | For rapid and precise construction of isogenic knockout strains to test FBA predictions. |

| Controlled Bioreactor (e.g., DASGIP, BioFlo) | Provides the stable, defined environmental conditions necessary for reproducible 13C MFA. |

This comparison guide is framed within a thesis context comparing Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C-MFA) validation methods. FBA, a constraint-based modeling approach, predicts fluxes using stoichiometry and optimization principles but lacks experimental validation of in vivo fluxes. 13C-MFA, in contrast, employs isotopic tracers (e.g., [1,2-13C]glucose) and mass spectrometry or NMR to experimentally quantify intracellular metabolic reaction rates. This guide objectively compares the application, performance, and data output of 13C-MFA against FBA and related alternatives in cancer and microbial systems.

Comparative Performance: 13C-MFA vs. Alternative Methods

The table below synthesizes current data on the quantitative performance of 13C-MFA compared to other metabolic modeling approaches.

Table 1: Comparison of Metabolic Flux Analysis Methods

| Feature | 13C-MFA | Flux Balance Analysis (FBA) | Kinetic Modeling | Transcriptomics/Proteomics-Based Inference |

|---|---|---|---|---|

| Quantitative Output | Absolute, validated fluxes (nmol/gDW/h) | Relative flux distribution (arbitrary units) | Dynamic flux and metabolite concentrations | Relative pathway activity (enrichment scores) |

| Experimental Basis | Direct measurement of isotope labeling in metabolites | Genome-scale stoichiometric model; no experimental fluxes required | Enzyme kinetic parameters & metabolite concentrations | mRNA/protein abundance levels |

| Temporal Resolution | Steady-state (hours) | Steady-state | Dynamic (ms to hours) | Snapshot (correlative) |

| Pathway Elucidation Power | High (resolves parallel pathways, reversible reactions) | Moderate (depends on model constraints; may have multiple solutions) | Very High (if parameters known) | Low (indirect correlation) |

| Throughput | Medium (sample prep, LC-MS/NMR) | High (computational only) | Low (parameter determination is bottleneck) | High (omics platforms) |

| Validation Requirement | Self-validating via measurement of labeling patterns | Requires 13C-MFA or exo-metabolite data for validation | Requires extensive time-series data | Requires flux validation for quantitative use |

| Typical Use Case | Definitive pathway quantitation (e.g., PPP vs. EMP split in cancer cells) | Hypothesis generation, gap-filling, exploring network capabilities | Detailed pathway dynamics (e.g., drug perturbation) | Large-scale screening for pathway target identification |

Key Experimental Protocols for 13C-MFA

Protocol: Steady-State 13C-MFA in Cancer Cell Lines

- Tracer Preparation: Prepare culture medium with a defined 13C-labeled carbon source. Common tracers include [U-13C]glucose (for glycolysis/TCA) or [1,2-13C]glucose (for Pentose Phosphate Pathway analysis).

- Cell Culturing & Quenching: Seed cancer cells (e.g., HeLa, MCF-7) and allow attachment. Replace medium with tracer medium. Culture until metabolic steady-state is reached (typically 24-48h, ensuring constant growth rate and labeling). Rapidly quench metabolism using cold (-40°C) 60% methanol.

- Metabolite Extraction & Derivatization: Perform a biphasic chloroform/methanol/water extraction. Collect the aqueous polar phase containing central carbon metabolites. Dry samples and derivatize (e.g., with MSTFA for GC-MS or TBDMS for amino acids).

- Mass Spectrometry Analysis: Analyze derivatized samples via GC-MS or LC-MS. For GC-MS, monitor key fragments of proteinogenic amino acids (reflecting labeling of precursor metabolites) and central metabolites.

- Modeling & Flux Computation: Use a stoichiometric model of the central metabolism. Input measured Mass Isotopomer Distributions (MIDs), extracellular uptake/secretion rates, and biomass composition. Employ software (e.g., INCA, OpenMebius) for least-squares regression to fit the fluxes that best reproduce the experimental MIDs. Statistical evaluation (χ²-test, Monte Carlo) provides confidence intervals for each calculated flux.

Protocol: 13C-MFA in Microbial Bioproduction Systems

- Chemostat Cultivation: Grow microbes (e.g., E. coli, S. cerevisiae) in a defined-medium chemostat at a fixed dilution rate to achieve metabolic and isotopic steady-state. Switch feed to an identical medium containing the 13C tracer.

- Sampling: After 5-7 residence times (ensuring full isotopic steady-state), sample the culture broth rapidly. Quench metabolism (cold methanol), separate cells, and process as in Protocol 1.

- Analysis & Flux Estimation: Follow similar MS analysis and computational fitting as above. The precise control of growth conditions in chemostats yields extremely accurate flux maps, crucial for metabolic engineering to optimize product (e.g., succinate, isobutanol) yield.

Visualizing 13C-MFA Workflow and Pathway Elucidation

13C-MFA Experimental Workflow

Central Carbon Metabolism with 13C Tracer Entry Points

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for 13C-MFA Experiments

| Item | Function in 13C-MFA | Example/Note |

|---|---|---|

| 13C-Labeled Substrates | Source of isotopic label for tracing carbon atoms through metabolism. | [U-13C]Glucose, [1,2-13C]Glucose, [13C5]Glutamine. Purity >99% atom 13C is critical. |

| Stable Isotope Analysis Software | Platform for metabolic modeling, isotopic simulation, and flux estimation. | INCA (Isotopomer Network Compartmental Analysis), OpenMebius, IsoCor. |

| GC-MS or LC-HRMS System | High-sensitivity instrument for measuring mass isotopomer distributions in metabolites. | GC-Q-MS for derivatized amino acids; LC-QTOF-MS for broader, underivatized polar metabolomics. |

| Quenching Solution | Rapidly halts enzymatic activity to preserve in vivo metabolic state. | Cold (-40°C to -80°C) 60% aqueous methanol. |

| Derivatization Reagents | Chemically modify metabolites for volatility (GC-MS) or improved ionization (LC-MS). | MSTFA (N-Methyl-N-(trimethylsilyl)trifluoroacetamide) for GC-MS. |

| Stoichiometric Model | Mathematical representation of the metabolic network for flux calculation. | Genome-scale (for context) or core central carbon model (for fitting). Available in BiGG Model database. |

| Chemostat Bioreactor | For microbial studies, maintains constant growth conditions essential for steady-state MFA. | Enables precise control of dilution rate, pH, and substrate feed. |

This comparison guide is framed within a broader thesis investigating validation methods for Flux Balance Analysis (FBA). FBA is a constraint-based modeling approach that predicts metabolic fluxes in genome-scale metabolic models (GSMMs). However, its predictions are inherently non-unique and require experimental validation. 13C Metabolic Flux Analysis (13C-MFA) is the gold standard for in vivo flux quantification in central metabolism. The integrative approach uses precise 13C-MFA data to constrain, refine, and validate genome-scale FBA models, transforming them from static maps into predictive, condition-specific simulation tools. This guide compares the performance of this integrative method against standalone FBA or 13C-MFA approaches.

Performance Comparison: Standalone FBA vs. 13C-MFA vs. Integrative Approach

Table 1: Core Methodological Comparison

| Feature | Standalone Genome-Scale FBA | Experimental 13C-MFA | Integrative FBA/13C-MFA |

|---|---|---|---|

| System Scope | Genome-scale (100s-1000s reactions) | Core metabolism (50-100 reactions) | Genome-scale, with core metabolism anchored by data |

| Primary Data Input | Stoichiometry, growth/uptake rates, objective function | 13C-labeling patterns, extracellular fluxes | All of the above + 13C-MFA flux constraints |

| Flux Solution | Non-unique; a solution space of possible fluxes | Unique, precise determination for core network | Reduced solution space; unique predictions for more reactions |

| Quantitative Accuracy | Low to moderate in core metabolism; unverified at scale | High in core metabolism | High in core metabolism; improved accuracy in peripheral pathways |

| Condition Specificity | Requires manual tuning of constraints | Inherently condition-specific | Automatically condition-specific via 13C data integration |

| Key Limitation | Lacks in vivo validation; relies on assumed objectives | Limited network scope; technically complex | Complexity of integration; requires multiple data types |

Table 2: Published Performance Metrics in E. coli and S. cerevisiae Studies

| Organism & Condition | Standalone FBA Prediction Error (Core Metabolism)* | 13C-MFA Experimental Error* | Integrative Model Prediction Error* | Key Improvement |

|---|---|---|---|---|

| E. coli (Aerobic, Glucose) | 25-40% RMSE for key fluxes (e.g., TCA, PPP) | <5% (well-designed experiment) | 5-10% RMSE for core fluxes | ~4x increase in core flux accuracy |

| S. cerevisiae (Anaerobic) | >50% error in redox balance predictions | <8% | 10-15% error for redox-coupled fluxes | Corrected electron shuttling pathways |

| Corynebacterium glutamicum (Lysine Prod.) | Failed to predict split TCA fluxes | <6% | Predicted anaplerotic fluxes within 12% | Enabled accurate prediction of product yield |

*RMSE: Root Mean Square Error compared to 13C-MFA reference fluxes. Errors are illustrative ranges from published literature.

Experimental Protocols for Key Integration Workflows

Protocol 1: Generating 13C-MFA Data for Model Validation

- Tracer Experiment: Grow cells in a chemostat or batch culture with a defined 13C-labeled substrate (e.g., [1-13C]glucose, [U-13C]glucose).

- Quenching & Extraction: Rapidly quench metabolism (e.g., cold methanol), extract intracellular metabolites.

- Mass Spectrometry (MS) Analysis: Analyze metabolite mass isotopomer distributions (MIDs) using GC-MS or LC-MS.

- Flux Estimation: Use software (e.g., INCA, 13C-FLUX2) to fit net fluxes and exchange fluxes to the measured MIDs and extracellular rates, obtaining a statistically validated flux map.

Protocol 2: Constraining a GSMM with 13C-MFA Data

- Model Curation: Start with a community consensus GSMM (e.g., iML1515 for E. coli, Yeast8 for S. cerevisiae).

- Flux Mapping: Map the quantitative fluxes from 13C-MFA onto the corresponding reactions in the GSMM.

- Application of Constraints: Apply the 13C-MFA fluxes as additional linear constraints (flux ≤ value ≤ flux) to the FBA problem, effectively "pinning down" the core metabolism.

- Re-optimization & Prediction: Run FBA with the new constraints. The model now must satisfy the core flux map and can make unique predictions for peripheral pathways (e.g., amino acid biosynthesis, cofactor cycling).

Protocol 3: Using 13C-MFA to Refine Model Gaps and Directionality

- Discrepancy Analysis: Compare standalone FBA flux ranges to 13C-MFA values. Identify reactions where predictions and data disagree.

- Gap Filling: If a required active flux is missing from the model, propose and add a missing enzyme reaction (e.g., a transhydrogenase, shuttle).

- Directionality Correction: If the model allows thermodynamically infeasible reversible flux that contradicts 13C data, adjust the reaction bounds to reflect in vivo directionality.

- Objective Function Testing: Test different biological objectives (max growth, min ATP, etc.) against the 13C-MFA data to infer the cell's true metabolic objective.

Visualizations

Title: Integrative Model Validation Workflow

Title: Core-Constrained Genome-Scale Flux Prediction

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Integrative 13C-MFA/FBA Studies

| Item | Function in Workflow | Example/Notes |

|---|---|---|

| 13C-Labeled Substrates | Tracer for 13C-MFA experiments to track metabolic pathways. | [1-13C]Glucose, [U-13C]Glucose; essential for generating labeling data. |

| GC-MS or LC-MS System | Analytical instrument to measure Mass Isotopomer Distributions (MIDs) of metabolites. | High sensitivity and resolution required for accurate MID measurement. |

| Quenching Solution | Rapidly halts cellular metabolism to capture an accurate metabolic snapshot. | Cold aqueous methanol (60%) is standard for microbial cultures. |

| Metabolite Extraction Kit | Efficiently extracts intracellular metabolites for MS analysis. | Kits often use methanol/water/chloroform phases for comprehensive coverage. |

| 13C-MFA Software | Computational platform to calculate fluxes from labeling data. | INCA, 13C-FLUX2, OpenFLUX. Uses non-linear fitting algorithms. |

| Genome-Scale Model (GSMM) | Computational representation of metabolism for FBA. | Community models: iML1515 (E. coli), Yeast8 (S. cerevisiae). |

| Constraint-Based Modeling Suite | Software to run FBA and integrate 13C constraints. | COBRA Toolbox (MATLAB), COBRApy (Python), CellNetAnalyzer. |

| Isotopic Spectral Library | Database for identifying and quantifying metabolites from MS fragmentation patterns. | In-house or commercial libraries (e.g., NIST) are critical for MID analysis. |

Navigating Challenges: Troubleshooting Common Pitfalls in Flux Analysis

Within the ongoing research thesis comparing Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (MFA) validation methods, a critical area of investigation is the systematic troubleshooting of common FBA pitfalls. FBA, a constraint-based modeling approach, is powerful for predicting metabolic fluxes in silico but is susceptible to issues arising from model incompleteness, mathematical degeneracy, and biologically implausible predictions. This guide compares the performance of standard FBA against advanced troubleshooting algorithms when benchmarked with experimental 13C MFA data, the gold standard for in vivo flux measurement.

Performance Comparison: Standard FBA vs. Advanced Troubleshooting Methods

The following table summarizes key performance metrics from recent validation studies, where FBA predictions were compared to experimental fluxes resolved by 13C MFA in E. coli and S. cerevisiae.

Table 1: Validation Metrics for FBA Troubleshooting Approaches vs. 13C MFA

| Method / Algorithm | Avg. Normalized RMSD vs. 13C MFA* | Prediction of Key Product Yield (g/g) | Unique Solution Guarantee? | Computational Cost (Relative Units) |

|---|---|---|---|---|

| Standard Linear FBA | 0.45 - 0.60 | 0.48 | No | 1.0 |

| Parsimonious FBA (pFBA) | 0.35 - 0.50 | 0.46 | Yes | 1.2 |

| Loopless FBA (ll-FBA) | 0.40 - 0.55 | 0.47 | No | 3.5 |

| Thermodynamic FBA (tFBA) | 0.25 - 0.40 | 0.42 | Yes | 15.0 |

| Integrative FBA-MFA | 0.15 - 0.25 | 0.44 | Yes | 10.0 |

*RMSD: Root Mean Square Deviation. Lower values indicate better agreement with 13C MFA experimental data. Ranges represent variation across multiple simulated growth conditions.

Experimental Protocols for Validation

Protocol 1: Benchmarking FBA Predictions Against 13C MFA

- Organism & Culture: Grow E. coli BW25113 in a controlled bioreactor under defined minimal media (e.g., M9 with 2 g/L glucose).

- 13C Labeling: Use [1-13C] glucose as the sole carbon source during mid-exponential phase.

- Metabolite Extraction & MS Analysis: Quench metabolism rapidly, extract intracellular metabolites. Analyze proteinogenic amino acid labeling patterns via Gas Chromatography-Mass Spectrometry (GC-MS).

- 13C MFA Flux Calculation: Input labeling data and uptake/secretion rates into software (e.g., INCA, 13C-FLUX2) to compute the statistically most likely flux map via iterative fitting.

- FBA Simulation: Constrain a genome-scale metabolic model (e.g., iJO1366 for E. coli) with identical experimental uptake/secretion rates and growth conditions. Run FBA and its variant algorithms to predict the flux distribution.

- Comparison: Calculate normalized RMSD between the FBA-predicted flux vector and the 13C MFA-derived flux vector for all reactions in the central carbon metabolism.

Protocol 2: Identifying Model Gaps via Growth Prediction Screens

- Knockout Library Screening: Utilize a genome-wide single-gene knockout collection (e.g., Keio collection for E. coli).

- Phenotypic Assay: Perform high-throughput growth assays on rich and minimal media.

- In silico Simulation: Simulate growth for each gene knockout using the FBA model by constraining the corresponding reaction(s).

- Discrepancy Analysis: Compare in silico predictions (growth/no growth) with experimental data. False predictions (e.g., model predicts growth but experiment shows no growth) highlight potential model gaps (missing isozymes, regulatory constraints, or transport reactions).

- Gap Filling: Propose and iteratively test the addition of biochemical reactions from databases (e.g., ModelSEED, BRENDA) to resolve false predictions.

Visualizing FBA Troubleshooting Workflows

Diagram 1: FBA Troubleshooting Decision Pathway

Diagram 2: FBA-13C MFA Integrative Validation

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for FBA Troubleshooting & Validation Experiments

| Item / Reagent | Function in Context | Example Product / Specification |

|---|---|---|

| 13C-Labeled Substrate | Provides tracer for 13C MFA to measure in vivo fluxes. | [1-13C] Glucose, >99% isotopic purity (Cambridge Isotope Laboratories). |

| Defined Minimal Media | Enables precise control of nutrient constraints for both FBA and culturing. | M9 salts, with defined carbon source concentration. |

| Genome-Scale Metabolic Model | The in silico representation of metabolism for FBA simulations. | E. coli iJO1366, S. cerevisiae Yeast8. (From BiGG Models). |

| Metabolite Quenching Solution | Instantly halts metabolism to capture in vivo flux state for 13C MFA. | 60% methanol (v/v) buffered with HEPES or Tricine, kept at -40°C. |

| Constraint-Based Modeling Software | Platform to run FBA and advanced troubleshooting algorithms. | COBRA Toolbox (MATLAB), cobrapy (Python), or CellNetAnalyzer. |

| 13C MFA Software Suite | Calculates metabolic fluxes from mass isotopomer distribution data. | INCA (Isotopomer Network Compartmental Analysis), 13C-FLUX2. |

| GC-MS System | Instrument for measuring the 13C labeling patterns of metabolites. | Equipped with a DB-5MS capillary column for amino acid derivative analysis. |

Within the ongoing methodological debate comparing Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (MFA) for model validation, a critical challenge lies in the robust experimental execution of 13C-MFA. This guide compares strategies and tools for mitigating its three most persistent technical pitfalls: experimental noise, isotopic label dilution, and underdetermined network configurations.

Comparison of Noise-Reduction & Data Processing Platforms

| Platform/Approach | Core Function | Key Metric for Noise Handling | Supported Data Inputs | Suitability for Large Networks |

|---|---|---|---|---|

| INCA 2.0 | Comprehensive MFA suite | Residual Sum of Squares (RSS) minimization with Monte Carlo confidence intervals | GC-MS, LC-MS, NMR | High (with careful model pruning) |

| OpenFLUX 2 / elementary metabolite units (EMU) | Algorithmic framework for flux estimation | Efficient computation of EMU variances for error propagation | MS isotopic labeling data | Very High (optimized for complex systems) |

| Isodyn | Parallel fitting & statistical analysis | Global fitting with batch experiment integration to reduce parameter uncertainty | Time-course MS data | Moderate |

| 13CFLUX2 | High-resolution flux mapping | Advanced correction for natural isotope abundances & mass isotopomer distributions (MIDs) | High-resolution MS (HR-MS) | High |

| MetaSys | Suite for constraint-based modeling & MFA integration | Uses experimental flux confidence intervals to refine FBA constraints | MS data, exchange fluxes | Designed for integration |

Protocol: Tracer Experiment Design for Minimizing Label Dilution

- Objective: Achieve high enrichment in target metabolic pathways to reduce uncertainty from unlabeled carbon sources.

- Cell Culture & Labeling: Grow cells to mid-exponential phase in unlabeled medium. Wash and transfer to custom labeling medium containing a single, universally labeled carbon source (e.g., [U-13C]glucose) at >99% purity. Maintain for a duration exceeding 5-6 cell doublings to reach isotopic steady state in biomass components.

- Quenching & Extraction: Rapidly quench metabolism using 60% aqueous methanol at -40°C. Extract intracellular metabolites using a chloroform:methanol:water (2:2:1) mixture.

- Derivatization & Analysis: Derivatize proteinogenic amino acids via tert-butyldimethylsilyl (TBDMS) and analyze via GC-MS. Acquire mass isotopomer distributions (MIDs) for fragments retaining the original carbon skeleton.

- Data Correction: Apply natural isotope abundance correction to the raw MIDs using the instrument's software or dedicated packages (e.g.,

MIDcorin MATLAB).

Comparison of Strategies for Underdetermined Networks

| Strategy | Principle | Tools Enabling It | Advantage | Disadvantage |

|---|---|---|---|---|

| Network Reduction (Parsimonious FBA) | Minimizes total flux sum while fitting 13C data | COBRApy with INCA |

Reduces degrees of freedom; physiologically plausible. | May exclude relevant alternate pathways. |

| Multi-Tracer Parallel Experiments | Uses complementary tracers ([1,2-13C]glucose, [U-13C]glutamine) to overdetermine system | 13CFLUX2, IsoSolve |

Empirically resolves more fluxes; gold standard. | Expensive, requires more cell culture & MS time. |

| Fluxomics Integration (FBA-MFA) | Uses FBA solution space as prior for 13C-MFA fitting | MetaFlux in MetaSys, CELL |

Leverages genomics data; provides bounded solutions. | Dependent on accuracy of FBA model constraints. |

| Omics-Constrained MFA | Incorporates quantitative proteomics to fix enzyme turnover limits | GECKO model with MFA |

Adds mechanistic constraints based on enzyme capacity. | Requires extensive proteomics data and kcat values. |

13C-MFA Workflow with Key Troubleshooting Points

The Scientist's Toolkit: Essential Reagents & Software

| Item | Function in 13C-MFA |

|---|---|

| [U-13C]Glucose (99% purity) | Primary tracer for central carbon metabolism; enables mapping of glycolysis, PPP, and TCA cycle fluxes. |

| Quenching Solution (60% MeOH, -40°C) | Instantly halts metabolism to capture true intracellular isotopic labeling state. |

| Derivatization Agent (MTBSTFA) | Adds tert-butyldimethylsilyl groups to amino acids for volatile, fragmentable GC-MS analysis. |

| INCA or 13CFLUX2 Software | Core platform for modeling metabolic networks, simulating MIDs, and performing non-linear regression for flux estimation. |

| GC-MS with Electron Impact Ionization | Workhorse instrument for measuring mass isotopomer distributions of derivatized metabolites. |

| Isotopic Standard Mix | A defined mix of unlabeled and labeled metabolites for correcting instrumental drift and quantifying enrichment. |

COBRA Toolbox (COBRApy) |

For generating flux constraints from genome-scale models to reduce underdetermination in 13C-MFA. |

FBA vs MFA Validation Thesis Context

Within the ongoing research thesis comparing Flux Balance Analysis (FBA) and 13C Metabolic Flux Analysis (13C MFA) validation methods, a critical advancement is the integration of thermodynamic and kinetic constraints into FBA frameworks. This guide compares the performance of standard FBA against its constrained variants (thermodynamic FBA, tFBA; and kinetic FBA, kFBA) using experimental data, highlighting how these integrations bridge the gap between FBA's genome-scale predictions and 13C MFA's empirical precision.

Performance Comparison: Standard FBA vs. Constrained FBA

The following table summarizes key performance metrics from recent studies comparing prediction accuracy against 13C MFA-derived fluxes, considered the gold standard for in vivo flux quantification.

Table 1: Comparison of FBA Variants Against 13C MFA Validation Data

| Method | Core Principle | Typical Correlation with 13C MFA (R²) | Key Advantage | Primary Limitation |

|---|---|---|---|---|

| Standard FBA | Linear optimization of an objective (e.g., biomass) subject to stoichiometric constraints. | 0.3 - 0.6 | High scalability; genome-wide coverage. | Ignores metabolite concentrations and enzyme kinetics; often predicts infeasible cycles. |

| tFBA (Thermodynamic FBA) | Incorporates Gibbs free energy constraints to ensure reaction directionality aligns with thermodynamic feasibility. | 0.5 - 0.75 | Eliminates thermodynamically infeasible loops; improves flux directionality prediction. | Requires estimation of metabolite concentrations; sensitive to ΔG°' and pH assumptions. |

| kFBA / k-OFBA (Kinetic FBA) | Integrates approximate kinetic constraints (e.g., Michaelis-Menten, enzyme capacity) based on omics data. | 0.6 - 0.85 | Predicts more realistic flux distributions under different conditions; can simulate metabolite dynamics. | Relies heavily on accurate kinetic parameters (often scarce); increased model complexity. |

| 13C MFA (Validation Standard) | Tracer experiment using 13C-labeled substrates to infer in vivo net and exchange fluxes via isotopomer modeling. | 1.0 (Self) | Provides empirical, condition-specific flux maps with high confidence. | Experimentally intensive; limited to central carbon metabolism scale. |

Experimental Protocols for Validation

The superiority of constrained FBA methods is demonstrated through structured validation against 13C MFA.

Protocol 1: tFBA Validation Workflow

- Model Preparation: Start with a genome-scale metabolic model (e.g., E. coli iJO1366).

- Constraint Addition:

- Compile literature data for metabolite concentration ranges ([Met]min, [Met]max) and standard Gibbs free energy (ΔG°').

- Apply the reaction affinity constraint: ΔG = ΔG°' + RT * ln(Q) < 0 for forward flux, where Q is the mass-action ratio.

- Implement using methods like Thermodynamic Flux Balance Analysis (tFBA) or Network-Embedded Thermodynamic (NET) analysis.

- Simulation: Perform FBA maximizing for biomass yield under defined growth conditions.

- Validation: Compare predicted fluxes for central metabolism (e.g., glycolysis, TCA cycle) to fluxes determined via 13C MFA from a parallel cultivation experiment. Calculate correlation (R²) and root-mean-square error (RMSE).

Protocol 2: k-OFBA (Kinetic and Optimization FBA) Benchmarking

- Data Collection: For the organism/condition of interest, gather proteomics data (enzyme concentrations, E_total) and literature-derived apparent Km values for key reactions.

- Kinetic Constraint Formulation: Apply a coarse-grained kinetic constraint: v ≤ kcat * Etotal. Incorporate elasticity approximations for substrate/Product inhibition if data exists.

- Model Integration: Integrate constraints as upper bounds in the linear programming problem or use the k-OFBA framework to find fluxes consistent with both stoichiometry and kinetic limits.