FBA in Metabolic Engineering: A Comprehensive Protocol for Rational Strain Design and Optimization

This article provides a detailed, step-by-step guide to applying Flux Balance Analysis (FBA) for rational strain design in metabolic engineering, tailored for researchers and industry professionals.

FBA in Metabolic Engineering: A Comprehensive Protocol for Rational Strain Design and Optimization

Abstract

This article provides a detailed, step-by-step guide to applying Flux Balance Analysis (FBA) for rational strain design in metabolic engineering, tailored for researchers and industry professionals. We begin by establishing the foundational principles of constraint-based modeling and genome-scale metabolic reconstructions (GEMs). The core methodology is then presented, covering the formulation of an FBA protocol from model selection to simulation and target identification. The guide addresses common pitfalls in FBA-driven design, offering solutions for model gaps, thermodynamic feasibility, and prediction accuracy. Finally, we explore advanced methods for validating computational predictions through 13C-MFA and comparative analysis with other strain design algorithms like OptKnock and MOMA. This protocol empowers the systematic engineering of microbial cell factories for the production of biofuels, pharmaceuticals, and fine chemicals.

The Blueprint of Life: Understanding Constraint-Based Modeling and GEMs for FBA

Flux Balance Analysis (FBA) is a mathematical and computational framework for analyzing the flow of metabolites through a metabolic network. It is a constraint-based modeling approach used to predict the growth rate of an organism or the rate of production of a biotechnologically relevant metabolite. FBA is a cornerstone of systems metabolic engineering, enabling in silico strain design for improved chemical production.

Core Mathematical Principles

FBA is formulated as a linear programming (LP) problem. The central equation is the stoichiometric mass balance:

S ⋅ v = 0

Where:

- S is the m x n stoichiometric matrix. m is the number of metabolites, and n is the number of metabolic reactions. Each element Sᵢⱼ represents the stoichiometric coefficient of metabolite i in reaction j.

- v is the n-dimensional vector of metabolic reaction fluxes (typically in mmol/gDW/h).

This equation represents the assumption of a steady-state, where the production and consumption of each intracellular metabolite are balanced.

The LP problem is then defined as: Maximize (or Minimize) Z = cᵀv Subject to:

- S ⋅ v = 0 (Steady-state mass balance)

- vₗb ≤ v ≤ vᵤb (Capacity constraints, defining lower and upper bounds for each flux)

Here, c is a vector of coefficients that defines the objective function, such as biomass production or target metabolite secretion.

Core Assumptions

FBA relies on several key assumptions, which are both its strength and its limitation.

| Assumption | Mathematical Representation | Biological Implication & Consequence |

|---|---|---|

| Steady-State | S ⋅ v = 0 | Intracellular metabolite concentrations do not change over time. Valid for balanced growth conditions but ignores dynamic transitions. |

| Mass Balance | Embedded in S | All metabolites are conserved. No synthesis from unspecified sources. |

| Network Stoichiometry is Known & Complete | Fixed S matrix | Predictions are only as good as the underlying genome-scale metabolic reconstruction (GEM). Gaps can limit predictive power. |

| Optimization Principle | Maximize cᵀv | The cell operates to optimize a biological objective (e.g., maximization of growth rate). This is a hypothesis, not a law. |

| Constraints Define Solution Space | vₗb ≤ v ≤ vᵤb | The feasible set of flux distributions is defined by environmental conditions (e.g., substrate uptake) and enzyme capacities. |

| Linear System | All constraints and objectives are linear | Enables efficient computation via linear programming but precludes modeling of nonlinear kinetics (e.g., allosteric regulation). |

Application Notes: FBA Protocol for Strain Design

This protocol outlines the steps for using FBA to predict gene knockout targets for overproduction of a desired compound.

Prerequisites & Materials

Research Reagent Solutions & Key Materials

| Item | Function/Explanation |

|---|---|

| Genome-Scale Metabolic Model (GEM) | A structured, organism-specific knowledge base detailing all known metabolic reactions, genes, and stoichiometry. The foundational input for FBA (e.g., E. coli iJO1366, Yeast 8). |

| Constraint-Based Reconstruction and Analysis (COBRA) Toolbox | A MATLAB/Julia/Python software suite providing functions for loading models, applying constraints, running FBA, and performing strain design algorithms. |

| Linear Programming (LP) Solver | Computational engine (e.g., GLPK, CPLEX, Gurobi) integrated with the COBRA toolbox to solve the optimization problem. |

| Experimental Data (Optional but Recommended) | Data on substrate uptake rates, growth rates, or byproduct secretion to refine model constraints (vₗb, vᵤb) and improve prediction accuracy. |

Experimental Protocol:In SilicoGene Knockout Prediction

Step 1: Model Curation and Preparation

- Obtain a high-quality GEM for your host organism from a repository like BiGG Models or ModelSEED.

- Validate the model by simulating growth on known carbon sources (e.g., glucose minimal medium) and comparing the predicted growth rate and essential genes with literature data.

- Set the objective function vector (c) to maximize biomass reaction flux.

- Define environmental constraints:

- Set lower bound (vₗb) of glucose exchange reaction to, e.g., -10 mmol/gDW/h (negative denotes uptake).

- Set lower bound of oxygen exchange reaction as required (e.g., -20 mmol/gDW/h for aerobic conditions).

- Set lower bounds of all other exchange reactions to 0 (no uptake) unless specified.

Step 2: Wild-Type Simulation

- Perform an FBA simulation on the unperturbed (wild-type) model.

- Record the maximum predicted biomass yield and any byproduct secretion fluxes.

- This serves as the baseline for comparison.

Step 3: Define Production Objective

- Identify the exchange reaction for the target biochemical (e.g., succinate).

- Create a new objective function vector (c_target) that maximizes the flux through this exchange reaction.

- Optionally, perform a Biomass-Product Coupled Yield (BPCY) analysis by setting the objective to maximize (ProductFlux * BiomassFlux).

Step 4: Knockout Simulation & Identification

- Employ a strain design algorithm:

- OptKnock: A bi-level optimization that identifies knockouts that maximize product synthesis while coupling it to growth. (Implement using

optKnockin COBRApy). - Robustness Analysis: Manually or iteratively set the flux through candidate reaction(s) to zero and simulate for both biomass and product formation.

- OptKnock: A bi-level optimization that identifies knockouts that maximize product synthesis while coupling it to growth. (Implement using

- For each candidate knockout set, run two FBA simulations:

- Simulation A: Maximize biomass. Record growth rate.

- Simulation B: Maximize target product secretion. Record production rate.

- Filter results:

- Eliminate designs where Simulation A predicts zero or negligible growth (lethality).

- Rank remaining designs by the production rate from Simulation B and/or the BPCY metric.

Step 5: In Silico Validation & Refinement

- Perform a Flux Variability Analysis (FVA) for the top knockout designs to assess the range of possible product fluxes at maximum growth.

- Analyze the predicted flux distribution map to understand the rerouted metabolism.

- Critical: Check for the emergence of metabolic cycles or unrealistic flux loops in the solution.

Data Output and Interpretation

Table: Example In Silico Knockout Prediction for Succinate Overproduction in E. coli

| Knockout Target Gene(s) | Predicted Max. Growth Rate (1/h) | Predicted Max. Succinate Rate (mmol/gDW/h) | Succinate Yield (mol/mol Glucose) | Growth-Coupled? (Y/N) |

|---|---|---|---|---|

| Wild-Type | 0.88 | 0.0 | 0.00 | N |

| ΔldhA, ΔpflB | 0.72 | 12.5 | 0.65 | Y |

| ΔptsG, ΔpykF | 0.65 | 15.1 | 0.78 | Y |

| ΔackA, Δpta | 0.81 | 8.2 | 0.42 | N |

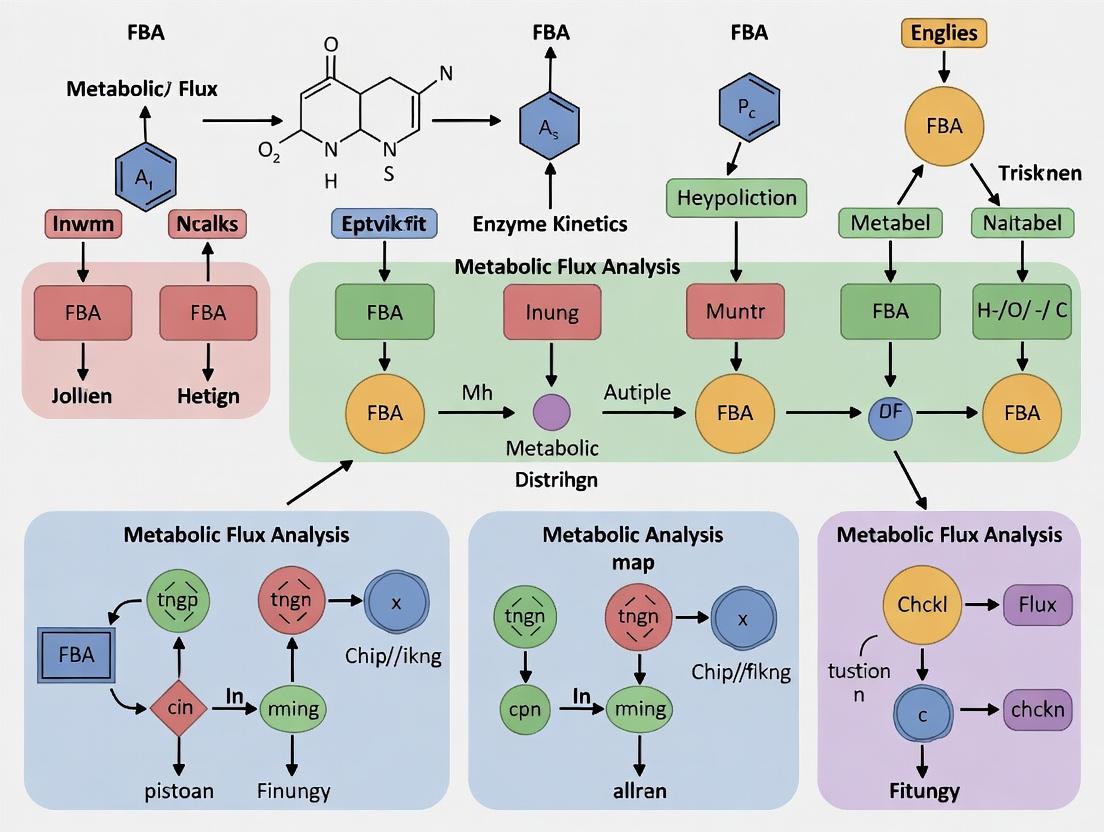

Visualization of Key Concepts

Flux Balance Analysis (FBA) Computational Workflow

Principle of Growth-Coupling via Targeted Knockout

The Critical Role of Genome-Scale Metabolic Reconstructions (GEMs)

Within the context of a metabolic engineering thesis focused on Flux Balance Analysis (FBA) for strain design, Genome-Scale Metabolic Reconstructions (GEMs) serve as the foundational computational scaffold. They are mathematical representations of an organism's metabolism, encompassing all known biochemical reactions, genes, and metabolites. The application of FBA on GEMs enables the prediction of optimal genetic modifications to engineer microbial strains for enhanced production of biofuels, pharmaceuticals, and biochemicals.

Application Notes

1. Strain Design for Biochemical Overproduction: GEMs are interrogated using FBA to identify gene knockout, knockdown, or overexpression targets that maximize the yield of a desired product while maintaining cellular viability. Algorithms such as OptKnock and MOMA are routinely applied to GEMs to predict strain designs.

2. Discovery of Novel Drug Targets: For pathogenic bacteria, GEMs can be analyzed to find essential genes under specific infection-relevant conditions. These genes represent potential targets for new antibiotics, as their inhibition would disrupt critical metabolic pathways.

3. Contextualization of Omics Data: Transcriptomic or proteomic data can be integrated into GEMs to create condition-specific models. This allows researchers to interpret high-throughput data in a functional metabolic context, identifying which pathways are active or repressed.

4. Comparative Analysis Across Species: GEMs for different organisms allow for the comparison of metabolic capabilities, aiding in the selection of optimal chassis organisms for metabolic engineering or understanding host-pathogen metabolic interactions.

Table 1: Key Quantitative Outputs from GEM-Based FBA for Strain Design

| Output Metric | Description | Typical Range/Value | Engineering Relevance |

|---|---|---|---|

| Maximum Theoretical Yield | Max moles of product per mole of substrate. | Varies by pathway (e.g., 0.5-1.0 for many products) | Defines the upper limit for process efficiency. |

| Essential Gene Count | Number of genes required for growth in silico. | ~100-300 in model bacteria (e.g., E. coli) | Identifies non-targetable housekeeping genes. |

| Predicted Growth Rate | Optimal growth rate (h⁻¹) under constraints. | 0.1 - 1.2 h⁻¹ for E. coli models | Benchmark for assessing design impact on fitness. |

| Flux Variability | Range of possible fluxes through a reaction. | Can be from zero to >1000 mmol/gDW/h | Identifies rigid vs. flexible network points. |

Detailed Protocols

Protocol 1: Performing FBA for Initial Strain Evaluation

Objective: To compute the maximal growth rate and production capacity of a native strain using a GEM.

Materials & Software:

- Genome-scale metabolic model (e.g., E. coli iML1515)

- Constraint-based modeling software (e.g., COBRApy in Python)

- Solver (e.g., GLPK, CPLEX, Gurobi)

Methodology:

- Model Loading: Import the GEM in SBML format into your modeling environment.

- Define Medium: Set the lower bounds of exchange reactions to define the substrate uptake (e.g., glucose at -10 mmol/gDW/h).

- Set Objective: Typically, set the biomass reaction as the objective function to maximize.

- Run FBA: Solve the linear programming problem to find the flux distribution that maximizes biomass.

- Extract Data: Record the optimal growth rate and the flux through a reaction of interest (e.g., a precursor for your target compound).

Protocol 2: Implementing OptKnock for Strain Design

Objective: To predict gene knockout strategies that couple product formation with growth.

Methodology:

- Prepare Model: Load the GEM and define the environmental conditions.

- Define Product: Identify the exchange reaction for the target biochemical (e.g., succinate).

- Formulate Bi-Level Optimization: OptKnock is a bi-level problem: inner problem maximizes biomass, outer problem maximizes product flux while allowing a limited number of reaction knockouts (e.g., up to 3).

- Solve: Use a mixed-integer linear programming (MILP) solver via an OptKnock implementation (e.g., in COBRApy or MATLAB).

- Validate Designs: Simulate growth and production of the knockout strain in silico using FBA to confirm coupling.

The Scientist's Toolkit

Table 2: Essential Research Reagents & Resources for GEM Work

| Item | Function / Description | Example / Source |

|---|---|---|

| Curated GEM | The core computational model of metabolism for an organism. | BiGG Models database (e.g., iML1515 for E. coli) |

| Constraint-Based Modeling Suite | Software toolbox for simulating and analyzing GEMs. | COBRA Toolbox (MATLAB), COBRApy (Python), Escher |

| MILP Solver | Software to solve optimization problems with integer constraints (e.g., for OptKnock). | Gurobi, CPLEX, SCIP |

| Genome Annotation Tool | Platform to generate draft metabolic reconstructions from genomic data. | ModelSEED, RAVEN Toolbox |

| Flux Visualization Tool | Software to visualize predicted flux distributions on pathway maps. | Escher, CytoScape |

| Omics Data Integration Suite | Tools to integrate transcriptomics/proteomics data into GEMs. | GIMME, iMAT, INIT (in COBRA Toolbox) |

Visualizations

Title: Core FBA Workflow on a GEM

Title: Logic of Computational Strain Design

Flux Balance Analysis (FBA) is a cornerstone computational method in metabolic engineering for predicting optimal metabolic fluxes in stoichiometrically-defined metabolic networks. Its power in strain design derives from the systematic imposition of physico-chemical and biological constraints that bound the solution space of feasible metabolic states. The accuracy of FBA predictions for designing production strains is critically dependent on the correct definition of three core constraints: Stoichiometry, Thermodynamics, and Enzyme Capacity. This application note details protocols for integrating these constraints into a robust FBA workflow for metabolic engineering research.

Core Constraint Definitions and Quantitative Data

Stoichiometric Constraints

These are the fundamental mass-balance constraints derived from the biochemical reaction network. They are mathematically represented as S · v = 0, where S is the stoichiometric matrix (m metabolites x n reactions) and v is the flux vector. These constraints ensure mass conservation.

Table 1: Key Components of a Stoichiometric Matrix for a Core Network

| Metabolite / Reaction | v_GLCt (Glucose Transport) | v_ATPase (Maintenance ATP) | v_BIOMASS (Growth) | v_PRODUCT (Target Compound) |

|---|---|---|---|---|

| Glucose_ext | -1 | 0 | 0 | 0 |

| Glucose | 1 | 0 | -a | -b |

| ATP | -1 | -1 | -c | -d |

| Product | 0 | 0 | 0 | 1 |

| Constraint Type | Upper/Lower Bound | Fixed Flux | Objective | Measured Rate |

(Coefficients a, b, c, d are derived from empirical biomass and product composition studies).

Thermodynamic Constraints

These constraints eliminate flux solutions that are thermodynamically infeasible by enforcing directionality. They are applied as inequality constraints on reaction fluxes (lb ≤ v ≤ ub). Thermodynamic Feasibility Analysis (TFA) integrates estimated Gibbs free energy (ΔG) to set directionality.

Table 2: Thermodynamic Parameters for Example Reactions

| Reaction ID | Reaction Formula | Typical ΔG'° (kJ/mol) | Computed ΔG (in vivo) | Implied Flux Bound (lb) |

|---|---|---|---|---|

| PFK | F6P + ATP → FBP + ADP + H+ | -14.2 | -25 to -40 | 0 ≤ v ≤ 1000 |

| FBA | FBP → G3P + DHAP | +23.8 | -5 to +5 | -1000 ≤ v ≤ 1000 |

| PDH | Pyruvate + CoA + NAD+ → AcCoA + CO2 + NADH | -33.5 | -50 to -60 | 0 ≤ v ≤ 1000 |

Enzyme Capacity Constraints

These are kinetic constraints that limit the maximum flux through a reaction based on the enzyme's turnover number (kcat) and available enzyme concentration (v_max = [E] * kcat). Integrating these transforms FBA into a Resource Balance Analysis (RBA) or Metabolism and Expression (ME) model.

Table 3: Enzyme Kinetic Parameters for Core E. coli Reactions

| Enzyme (Gene) | EC Number | kcat (s⁻¹) | Typical in vivo [E] (μM) | Calculated v_max (mmol/gDW/h) | Reference Organism |

|---|---|---|---|---|---|

| PfkA (pfkA) | 2.7.1.11 | 250 | 5.2 | ~190 | E. coli K-12 |

| PykF (pykF) | 2.7.1.40 | 465 | 9.1 | ~430 | E. coli K-12 |

| AceE (aceE) | 1.2.4.1 | 58 | 1.8 | ~22 | E. coli K-12 |

Detailed Experimental Protocols

Protocol 1: Constructing a Stoichiometrically-Balanced Genome-Scale Model (GEM)

Objective: To build a high-quality GEM for constraint-based analysis.

- Reconstruction:

- Source a template GEM (e.g., EcoCyc, BiGG Models like iML1515 for E. coli).

- Use genomic annotation and literature to add/remove species-specific reactions.

- Mass and Charge Balancing:

- For each reaction, ensure atoms (C, H, O, N, P, S) and charge are balanced using tools like

COBRApy(cobra.flux_analysis.check_mass_balance). - For unbalanced reactions, add or modify cofactors (H2O, H+, ATP) or consult biochemical databases (BRENDA, MetaCyc).

- For each reaction, ensure atoms (C, H, O, N, P, S) and charge are balanced using tools like

- Biomass Equation Formulation:

- Compile quantitative data on cellular composition (protein, RNA, DNA, lipids, carbohydrates, cofactors) from literature for the target organism and growth condition.

- Assemble precursors with their molar contributions into a single biomass synthesis reaction.

- Validation: Test model's ability to predict essential genes and growth rates on different carbon sources against experimental data.

Protocol 2: Integrating Thermodynamic Constraints via TFA

Objective: To constrain reaction directions using estimated Gibbs free energy.

- Data Collection:

- Gather standard Gibbs free energies of formation (ΔfG'°) for all metabolites from databases (e.g., eQuilibrator, NIST).

- Calculate Reaction ΔG'°: ΔG'° = Σ(ΔfG'° products) - Σ(ΔfG'° reactants).

- Estimate in vivo ΔG: ΔG = ΔG'° + R T ln(Q), where Q is the reaction quotient. Use measured or estimated intracellular metabolite concentrations (from LC-MS/MS) to compute Q.

- Apply Directionality Constraints:

- If ΔG << 0 (e.g., < -20 kJ/mol), set lower bound (lb) = 0 for irreversible forward reaction.

- If ΔG >> 0 (e.g., > +20 kJ/mol), set upper bound (ub) = 0.

- For intermediate ΔG, the reaction may be reversible (-1000 ≤ v ≤ 1000).

- Implementation: Use the

thermotoolorCOBRApyTFA extension to convert the problem into a Mixed-Integer Linear Programming (MILP) formulation.

Protocol 3: Incorporating Enzyme Capacity Constraints

Objective: To limit fluxes by proteomic allocation.

- Determine Enzymatic Parameters:

- kcat: Retrieve from BRENDA or SABIO-RK. Prioritize values measured for the target organism under physiological conditions.

- [E]: Quantify enzyme abundance via proteomics (LC-MS/MS) or estimate from transcriptomics (RNA-Seq) data using conversion factors.

- Calculate vmax: vmaxi = [E]i * kcat_i * (3600 s/h) * (1e-3 mol/mmol). Convert to units of mmol/gDW/h.

- Formulate the Constraint: Add linear inequality: vi ≤ vmax_i for each reaction i.

- Global Proteome Constraint (Optional for RBA): Add a total protein constraint: Σ ([E]i / kcati) * |vi| ≤ Ptotal, where P_total is the total cellular protein mass fraction.

- Simulation: Solve the linear programming (LP) problem with the new upper bounds. Use

COBRApy'sadd_constraintfunction or specialized RBA software.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Constraint-Based Strain Design

| Item / Reagent | Function / Application |

|---|---|

| COBRA Toolbox (MATLAB) / COBRApy (Python) | Primary software suites for building, constraining, and simulating genome-scale models. |

| eQuilibrator API | Web-based tool for calculating thermodynamic parameters (ΔG'°, ΔG) of biochemical reactions. |

| LC-MS/MS System | Quantifying absolute intracellular metabolite concentrations for thermodynamic (Q) and flux analysis. |

| Proteomics Quantification Kit (e.g., TMT/iTRAQ) | For measuring absolute enzyme abundances ([E]) to set enzyme capacity constraints. |

| Biolog Phenotype Microarray Plates | High-throughput experimental validation of model-predicted growth phenotypes. |

| Strain Design Software (OptKnock, DESHER) | Algorithms that run on top of constrained models to identify gene knockout/overexpression targets. |

| Jupyter Notebook Environment | For reproducible scripting of the entire FBA workflow, from data integration to simulation. |

| Cultivation System (Bioreactor/Chemostat) | For generating high-quality, steady-state omics data (transcriptomics, proteomics) under defined conditions for model conditioning. |

Visualization of Workflows and Relationships

Title: Stoichiometric Model Reconstruction Workflow

Title: Hierarchical Addition of FBA Constraints

Title: Integrated FBA Constraint Protocol for Strain Design

Application Notes and Protocols

Within the framework of a thesis on Flux Balance Analysis (FBA) protocol for metabolic engineering strain design, the selection of an appropriate biological objective function is the critical computational step that translates a metabolic model into a predictive simulation. This choice directly dictates the predicted flux distribution and the subsequent genetic targets identified for strain improvement. This document provides application notes and experimental protocols for implementing and validating three primary objective function strategies.

1. Core Objective Functions in FBA

FBA simulates cellular metabolism under the assumption of steady-state mass balance and optimality. The linear programming problem is formulated as: Maximize: ( Z = c^T \cdot v ) Subject to: ( S \cdot v = 0 ), and ( v{min} \leq v \leq v{max} ) where ( c ) is the vector of weights for the objective function. The choice of ( c ) defines the physiological objective.

Table 1: Primary Objective Functions and Their Applications

| Objective Function | Vector (c) Configuration | Primary Application | Key Consideration |

|---|---|---|---|

| Maximize Biomass Growth | Weight = 1 for the biomass reaction; 0 for all others. | Predicting wild-type phenotypes, optimizing growth rate, and essentiality analysis. | May conflict with product formation; assumes growth is the cell's primary goal. |

| Maximize Product Yield | Weight = 1 for the specific secretion reaction of the target compound (e.g., succinate, ethanol). | Driving flux towards maximal theoretical yield of a biochemical, often under non-growth conditions. | Can predict unrealistic flux distributions if cellular maintenance is not accounted for. |

| Maximize Product Formation Rate | Weight = 1 for the product secretion reaction, often with a lower bound constraint on growth. | Maximizing productivity (titer/rate) in production strains. Balances growth and production. | Requires careful tuning of the growth constraint to reflect experimental conditions. |

2. Protocols for Implementing Objective Functions

Protocol 2.1: Formulating and Solving a Standard FBA Problem with Biomass Maximization

- Software: COBRA Toolbox for MATLAB/Python, cobrapy (Python).

- Procedure:

- Load Model: Import a genome-scale metabolic model (e.g., E. coli iJO1366, S. cerevisiae iMM904).

- Set Medium Constraints: Define the exchange reaction bounds to reflect the experimental culture medium (e.g., glucose uptake = -10 mmol/gDW/hr, oxygen uptake = -20 mmol/gDW/hr).

- Set Objective: Assign the reaction identifier for the biomass formulation (e.g.,

BIOMASS_Ec_iJO1366_core_53p95M) as the objective function with a weight of 1. - Solve: Apply the

optimizeCbModel(COBRA) oroptimize()(cobrapy) function to solve the linear programming problem. - Output Analysis: Extract the optimal growth rate, key flux values, and conduct flux variability analysis (FVA) to assess solution space.

Protocol 2.2: Designing for High-Yield Production using OptKnock

- Aim: Identify gene knockout strategies that couple growth with product formation.

- Methodology: Bi-level optimization (e.g., OptKnock).

- Procedure:

- Inner Problem: Maximize biomass formation.

- Outer Problem: Maximize flux through the target product secretion reaction.

- Constraint: Apply a lower bound for growth (e.g., >10% of wild-type) to ensure viability.

- Implementation: Use the

optKnockfunction (COBRA Toolbox) or analogous MILP solvers (e.g., Gurobi, CPLEX). - Output: A ranked list of gene knockout sets that theoretically force product secretion as a byproduct of growth.

Protocol 2.3: Experimental Validation of Model Predictions

- Aim: Test strain design predictions from FBA with different objective functions.

- Strains: Wild-type and engineered knockout/pathway strains.

- Cultivation:

- Use controlled bioreactors (e.g., DASGIP, BioFlo) for consistent environmental parameters.

- Employ defined minimal media matching FBA constraints.

- Monitor growth (OD600) and substrate (e.g., glucose) concentration offline or with online analyzers.

- Analytics:

- Extracellular Metabolites: Use HPLC (with RI/UV detection) or GC-MS to quantify substrate consumption and product formation (e.g., organic acids, ethanol).

- Calculation: Determine experimental yields (Yp/s), growth rates (μ), and production rates (Qp).

- Comparison: Correlate experimental data with FBA-predicted fluxes for the corresponding objective function scenario.

3. Visualization of FBA-Driven Strain Design Workflow

Title: FBA Objective Function Selection Drives Strain Design

4. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Model-Driven Strain Design and Validation

| Item | Function/Application | Example/Supplier |

|---|---|---|

| Genome-Scale Metabolic Model | In silico representation of organism metabolism for FBA. | BiGG Models Database (http://bigg.ucsd.edu/) |

| COBRA Software Suite | Primary computational toolbox for constraint-based modeling. | COBRA Toolbox (for MATLAB), cobrapy (for Python) |

| Commercial Linear/MILP Solver | Engine for solving optimization problems in FBA. | Gurobi Optimizer, IBM ILOG CPLEX |

| Defined Minimal Media | Essential for controlled experiments matching model constraints. | M9 (E. coli), Minimal SD (Yeast), Custom formulations |

| HPLC System with Detectors | Quantification of extracellular metabolites (substrates, products). | Agilent 1260 Infinity II (RI/UV/DAD), Bio-Rad Aminex HPX-87H column |

| GC-MS System | Broad profiling and quantification of volatile metabolites. | Agilent 8890/5977B, Thermo Scientific TRACE 1600/ISQ 7610 |

| Microbial Bioreactor System | Provides controlled, reproducible cultivation conditions for kinetics. | Eppendorf BioFlo 320, Sartorius Biostat STR, 2L-5L vessels |

| CRISPR/Cas9 Toolkit | Enables precise genetic knockouts/edits predicted by in silico design. | IDT Alt-R system, NEB HiFi DNA Assembly, strain-specific plasmids |

| Cell Growth Monitor | Real-time kinetic data for model validation (growth rate μ). | Cytation plate readers, offline OD600 spectrometer |

Essential Software and Databases for FBA (CobraPy, ModelSEED, BiGG)

Application Notes

Flux Balance Analysis (FBA) is a cornerstone of constraint-based metabolic modeling, essential for predicting optimal metabolic fluxes in engineered strains. Within a thesis focused on FBA protocols for strain design, the integration of specialized software and curated databases is critical for constructing, simulating, and validating genome-scale metabolic models (GEMs). This section details the core applications of three pivotal resources: the COBRApy toolbox, the ModelSEED database and pipeline, and the BiGG Models database. Their synergistic use enables a streamlined workflow from model reconstruction and gap-filling to simulation and biochemical contextualization.

COBRApy is the definitive Python package for implementing COnstraint-Based Reconstruction and Analysis. It provides the computational engine for formulating and solving linear optimization problems that represent metabolic networks under steady-state and capacity constraints. Its primary application in strain design is the in silico prediction of genetic modifications (e.g., gene knockouts, knock-ins) that optimize a desired objective function, such as the production rate of a target compound. Its flexibility allows for the implementation of advanced algorithms like OptKnock and Flux Variability Analysis (FVA).

ModelSEED accelerates the initial phases of metabolic model development. Its primary application is the rapid, automated reconstruction of draft GEMs from genome annotations. For non-model organisms or newly sequenced strains, ModelSEED provides a standardized pipeline for generating a functional metabolic network, complete with metabolite and reaction identifiers mapped to its biochemistry database. This is indispensable for initiating strain design projects where a pre-existing, curated model is unavailable.

BiGG Models serves as the gold-standard repository for highly curated, genome-scale metabolic models. Its primary application is as a reference database for biochemical knowledge. When refining a draft model (e.g., from ModelSEED) or constructing one manually, BiGG provides a consistent namespace for metabolites, reactions, and genes. Using BiGG identifiers ensures model components are correctly linked to external databases (e.g., KEGG, PubChem) and enables the direct comparison of simulation results across different published models.

Table 1: Quantitative Comparison of Core FBA Resources

| Feature | COBRApy | ModelSEED | BiGG Models |

|---|---|---|---|

| Primary Function | Simulation & Analysis Toolkit | Automated Model Reconstruction | Curated Model Database |

| Typical Release Cycle | Biannual GitHub Releases | Periodic Database Updates | Versioned Releases (e.g., 1.6) |

| Number of Core Reactions | N/A (Tool for any model) | >20,000 in Biochemistry | ~90,000 (Across all models) |

| Number of Curated GEMs | 0 (Hosts none) | 100,000+ Draft Models | 100+ High-Quality Models |

| Key Metric | >100+ Analysis Methods | ~80% Auto-completion for Draft Models | 100% Manual Curation per Model |

| Integration | Python API | Web App, API, CLI | Website, SBML Files |

Experimental Protocols

Protocol 2.1: Integrated Workflow forDe NovoStrain Design Using COBRApy, ModelSEED, and BiGG

Objective: To reconstruct a draft genome-scale metabolic model for a novel bacterial strain, refine it using biochemical data, and perform FBA to identify gene knockout targets for enhanced succinate production.

Materials & Reagent Solutions:

- Research-Genome Sequence: FASTA file of the annotated genome (

.faaor.gff). - Python Environment: Anaconda distribution with Python 3.9+.

- COBRApy: Installed via

pip install cobra. - ModelSEED API: Access via

pip install modelseedpy. - BiGG Model Data: Download SBML file for a reference organism (e.g., E. coli iJO1366) from http://bigg.ucsd.edu.

- Jupyter Notebook: For interactive analysis and documentation.

- Linear Programming Solver: e.g., GLPK (open-source) or CPLEX (commercial).

Procedure:

Part A: Draft Model Reconstruction with ModelSEED

- Prepare Genomic Input: Format the protein sequence file (

.faa) from your target strain. - Annotate with RAST: Upload the genome to the public RAST server (rast.nmpdr.org) or use the command-line tool

rast-tkto obtain functional roles for each gene. - Call ModelSEED Pipeline: Using the ModelSEEDpy API, submit the RAST annotation job ID to trigger the model reconstruction pipeline. This will map gene functions to ModelSEED roles and assemble associated reactions.

- Retrieve Draft Model: Download the output as an SBML file. This draft model will contain gaps (missing reactions required for growth).

Part B: Model Curation and Refinement with BiGG

- Namespace Standardization: Load the draft ModelSEED SBML into COBRApy. Write a script to map all metabolite and reaction identifiers from the ModelSEED namespace to the BiGG namespace using provided mapping tables from both projects.

- Gap-Filling & Validation: Perform a gap-filling simulation to identify minimal reaction additions that enable growth on a defined medium (e.g., M9 glucose). Use the

cobra.flux_analysis.gapfillingfunctions. Manually inspect and curate added reactions against BiGG's E. coli core model for biochemical accuracy. - Add Transport & Exchange Reactions: Based on experimental culture conditions, add relevant transport reactions using BiGG metabolite identifiers to ensure model boundaries are physiologically accurate.

Part C: FBA Simulation and Strain Design with COBRApy

- Define Objective & Constraints: Set the model objective function to maximize biomass. Constrain glucose uptake to a measured experimental rate (e.g., -10 mmol/gDW/hr). Set oxygen uptake if applicable.

- Run FVA for Succinate: Perform Flux Variability Analysis on the succinate exchange reaction to determine its maximum theoretical yield under growth conditions.

- Implement OptKnock: Use the

cobra.flux_analysisdouble gene deletion simulation or a custom OptKnock algorithm (formulated using thecobraoptimization objects) to identify gene knockout pairs that couple growth to succinate secretion. - Validate In Silico Predictions: Simulate growth and production after applying the predicted knockouts. Compare flux distributions before and after intervention.

Protocol 2.2: Comparative Analysis of Mutant Strains Using a Consensus BiGG Model

Objective: To evaluate the metabolic impact of an engineered knockout in E. coli by comparing flux distributions in the wild-type and mutant models.

Materials & Reagent Solutions:

- Curated SBML Models: Wild-type and mutant E. coli models (e.g., ∆ldhA) in BiGG-compliant format.

- COBRApy: As in Protocol 2.1.

- Pandas & Matplotlib Libraries: For data analysis and visualization.

- Experimental Data: Measured uptake/secretion rates (mmol/gDW/hr) for key metabolites.

Procedure:

- Model Loading & Constraining: Load both SBML models into COBRApy. Apply identical medium constraints using exchange reactions, based on your experimental culture conditions.

- Parsimonious FBA: Solve for a flux distribution that maximizes biomass yield while minimizing total absolute flux (

model.optimize()followed bycobra.flux_analysis.pfba). This yields a unique, energy-efficient solution. - Flux Comparison: Extract fluxes for all reactions. Calculate the absolute difference in flux (∆Flux = |Fluxmutant - Fluxwt|) for each reaction.

- Identify Key Redirects: Filter reactions with |∆Flux| > 1e-6. Sort to find reactions with the largest absolute changes. Focus on pathways upstream/downstream of the knockout and around the target product.

- Generate Flux Maps: Use the

cobra.flux_analysis.vizmodule or export flux values to external network visualization tools (e.g., Escher) to create comparative diagrams of central carbon metabolism.

Visualization Diagrams

Title: Integrated FBA Software Workflow for Strain Design

Title: Flux Redirection After ldhA Knockout for Succinate

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagents and Computational Materials for FBA-Based Strain Design

| Item | Function in Protocol | Specification / Notes |

|---|---|---|

| Annotated Genome Sequence | Raw input for model reconstruction. | FASTA format (.fna, .faa) or GFF3. Quality of annotation directly impacts model accuracy. |

| Defined Growth Medium | Provides constraints for exchange reactions in the model. | Must know exact composition (e.g., M9 + 20 g/L Glucose) to set reaction bounds. |

| Experimental Flux Data | Used to validate and constrain the in silico model. | Measured uptake/secretion rates (mmol/gDW/hr) from bioreactor or chemostat. |

| COBRApy Python Package | Core engine for building, manipulating, and simulating models. | Requires a linear programming solver (e.g., GLPK, CPLEX) as a backend. |

| BiGG Namespace Map | Critical for standardizing metabolite/reaction identifiers. | Mapping file (CSV/JSON) linking ModelSEED, KEGG, and BiGG IDs. |

| Jupyter Notebook | Environment for reproducible protocol execution. | Allows interactive visualization of flux results and documentation of steps. |

| SBML File | Interoperable format for storing and sharing metabolic models. | Level 3 Version 2 with the "fbc" package for COBRA constraints is standard. |

| Reference Biochemical Model | Template for curation and comparative analysis. | A well-curated model like E. coli iJO1366 from BiGG. |

From Model to Design: A Step-by-Step FBA Protocol for Strain Engineering

Application Notes

The foundation of any successful metabolic engineering project using Flux Balance Analysis (FBA) is a high-quality, well-curated Genome-Scale Metabolic Model (GEM). A GEM is a computational representation of the metabolic network of an organism, encapsulating genes, reactions, metabolites, and their stoichiometric relationships. Curating and contextualizing this model for a specific strain or experimental condition is the critical first step in the FBA protocol for strain design, ensuring predictions are biologically relevant and actionable.

Core Challenges & Solutions:

- Data Integration: Manual curation is essential to integrate organism-specific data from genomics, transcriptomics, and bibliomic sources, correcting gaps and errors in automated reconstructions.

- Contextualization: A generic model must be tailored to reflect the physiological state of the target strain under specific conditions (e.g., carbon source, knockout genes, nutrient limitations). This involves defining the biomass objective function, constraining uptake/secretion rates, and adjusting gene-protein-reaction (GPR) rules.

- Quality Assurance: Rigorous testing of model functionality through simulation of known growth phenotypes and essentiality profiles is required to validate predictive capacity.

Protocols & Methodologies

Protocol 1: Initial Model Acquisition and Assessment

Objective: Obtain a base model and evaluate its completeness and functionality for your target organism.

- Source Selection: Download the most recent community-agreed model for your organism from repositories like:

- BioModels

- BioCyc

- MetaNetX

- The BIGG Models Database

- Format Standardization: Convert the model into a consistent systems biology format (e.g., SBML) using tools like COBRApy or RAVEN Toolbox.

- Compatibility Check: Ensure the model can perform basic simulations (e.g., produce biomass under rich medium conditions) using a constraint-based modeling suite.

- Gap Analysis: Identify dead-end metabolites and blocked reactions using built-in diagnostic functions (e.g.,

checkMassBalance,findBlockedReactionin COBRApy). This highlights areas requiring manual curation.

Protocol 2: Manual Curation and Annotation Refinement

Objective: Improve model quality by incorporating strain-specific genomic and physiological data.

- Literature Mining: Systematically review recent literature on the organism's metabolism to gather evidence for:

- Alternative enzymatic functions or isozymes.

- Updated gene annotations (using databases like BRENDA, KEGG).

- Experimentally measured uptake/secretion rates.

- Reaction Curation: For each gap or questionable reaction:

- Verify existence and stoichiometry using biochemical databases.

- Update GPR associations with Boolean rules (AND/OR).

- Add transport reactions and exchange reactions to allow metabolite transfer between system boundary and environment.

- Biomass Equation Definition: Compose or refine the biomass objective function to represent the macromolecular composition (protein, DNA, RNA, lipids, carbohydrates) of your specific strain, ideally using experimental data.

Protocol 3: Model Contextualization for Experimental Condition

Objective: Constrain the generic model to reflect the specific experimental or industrial condition.

- Define Environmental Constraints: Set lower and upper bounds (

lb,ub) for exchange reactions based on measured substrate uptake rates and byproduct secretion profiles. Example: For glucose-limited chemostat data: Set the glucose exchange reaction upper bound to-5.0 mmol/gDW/h(negative for uptake). - Integrate Omics Data (Optional but Recommended): Use transcriptomic or proteomic data to further constrain the model.

- Apply GIMME, iMAT, or TRANSCRIPTIC algorithms (available in COBRA Toolbox extensions) to create a condition-specific model.

- This can "turn off" reactions associated with non-expressed genes.

- Validate with Experimental Data: Test the contextualized model's ability to predict:

- Growth rate (compare predicted vs. measured).

- Essential genes (perform in silico single-gene knockout and compare with essentiality screens).

- Substrate utilization patterns.

Data Presentation

Table 1: Comparison of Major Public Genome-Scale Model Databases

| Database | Primary Focus | Key Feature | Model Format | Update Frequency |

|---|---|---|---|---|

| BIGG | High-quality, manually curated models | Interactive web interface, reaction balancing | SBML, JSON | Continuous |

| BioModels | Broad collection of published models | Peer-reviewed, SBO annotations | SBML | Regular |

| MetaNetX | Integrated namespace mapping | Automated reconciliation of metabolites (MNXref) | SBML, MAT | Quarterly |

| BioCyc | Pathway/Genome Databases | Organism-specific metabolic maps | PGDB format | Regular |

Table 2: Common Model Curation Tasks and Tools

| Curation Task | Description | Recommended Tool/Resource |

|---|---|---|

| Gap Filling | Add missing reactions to allow biomass production | gapfill (COBRApy), ModelSEED |

| Mass/Charge Balancing | Verify reaction stoichiometry | Charge Balance Check (COBRA Toolbox), MetaNetX |

| GPR Assignment | Link genes to reactions via Boolean rules | SBO Term Annotations, manually via literature |

| Biomass Composition | Define macromolecular synthesis demands | Experimental data (e.g., HPLC, microscopy) |

| Boundary Definition | Set exchange reaction limits for media | Experimental uptake/secretion rates |

Visualizations

Title: GEM Curation and Contextualization Workflow

Title: From Generic to Context-Specific GEM

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in GEM Curation & Contextualization |

|---|---|

| COBRA Toolbox (MATLAB) | The standard software suite for constraint-based modeling. Used for simulation, gap filling, and integrating omics data. |

| COBRApy (Python) | Python version of COBRA, essential for automated, script-based model curation and large-scale analysis. |

| RAVEN Toolbox (MATLAB) | Specialized for reconstruction, curation, and simulation of GEMs, with strong integration to KEGG and MetaCyc. |

| MEMOTE (Python) | A community-developed tool for Model Metrics Tests. Automates quality assessment of genome-scale models against a standardized set of tests. |

| SBML (Systems Biology Markup Language) | The universal, XML-based file format for exchanging and archiving models. Essential for interoperability between tools. |

| Biomass Composition Dataset | Experimentally measured concentrations of amino acids, nucleotides, lipids, etc., in the target strain under defined conditions. Crucial for defining an accurate biomass objective function. |

| Experimentally Measured Flux Data | Data from 13C metabolic flux analysis (13C-MFA) or chemostat studies. The gold standard for validating and further constraining model predictions. |

| Curated Metabolic Database (e.g., MetaCyc, BRENDA) | Provides verified information on enzyme specificity, kinetic parameters, and associated reactions to support manual curation steps. |

1. Application Notes In metabolic engineering, the predictive power of Flux Balance Analysis (FBA) is contingent upon a biologically realistic simulation environment. This step translates the abstract metabolic network (Reconstruction) into a context-specific model by imposing quantitative physiological constraints. These constraints define the permissible solution space for flux distributions, aligning in silico predictions with in vivo cellular behavior. For strain design, accurate constraints are critical for identifying actionable genetic modifications that will yield the desired phenotype under specified cultivation conditions.

2. Key Constraint Categories & Data Presentation Quantitative constraints are derived from experimental literature and -omics data. The following table summarizes the primary constraint types and their impact.

Table 1: Core Physiological Constraints for FBA-Based Strain Design

| Constraint Category | Description | Typical Data Source | FBA Implementation |

|---|---|---|---|

| Nutrient Uptake | Maximal uptake rates for carbon, nitrogen, oxygen, etc. | Chemostat experiments, Bioreactor profiles. | Upper bound (ub) on exchange reaction (e.g., EX_glc__D_e). |

| Growth Requirements | Non-growth associated maintenance (NGAM) and growth-associated maintenance (GAM) ATP costs. | Calorimetry, literature compilations. | Lower bound (lb) on ATP maintenance reaction (ATPM). |

| Byproduct Secretion | Observed secretion rates of metabolites like acetate, ethanol, or CO2. | Metabolite profiling, off-gas analysis. | Upper/lower bounds on respective exchange reactions. |

| Enzyme Capacity | Maximal turnover (kcat) and measured enzyme abundances. | Proteomics data, enzyme assays. | Thermodynamic-based (ETFL) or linear constraints. |

| Regulatory Limits | Knock-out/knock-down of specific reactions. | Gene essentiality studies, CRISPRi screens. | Set reaction flux bounds to zero or a reduced value. |

| Biomass Composition | Detailed macromolecular makeup of the cell (protein, RNA, DNA, lipids). | Literature, multi-omics integration. | Coefficients in the biomass objective function reaction. |

Table 2: Example Quantitative Constraints for E. coli in a Glucose-Limited Bioreactor

| Parameter | Symbol | Value | Unit | Reaction ID |

|---|---|---|---|---|

| Glucose Uptake Rate | vGlc | -10 | mmol/gDW/h | EX_glc__D_e |

| Oxygen Uptake Rate | vO2 | -18 | mmol/gDW/h | EX_o2_e |

| Non-Growth Maintenance | NGAM | 8.39 | mmol ATP/gDW/h | ATPM |

| Growth-Assoc. Maintenance | GAM | 59 | mmol ATP/gDW | (Biomass reaction) |

| Max Acetate Secretion | vAce | 2.0 | mmol/gDW/h | EX_ac_e |

3. Experimental Protocols for Constraint Determination

Protocol 3.1: Chemostat Cultivation for Steady-State Flux Data Objective: Determine precise substrate uptake and byproduct secretion rates under nutrient-limited, steady-state growth. Materials: Bioreactor system, defined minimal media, gas analyzer, spectrophotometer, HPLC/GC-MS. Procedure:

- Inoculate bioreactor with strain of interest in defined medium with limiting nutrient (e.g., 0.2% w/v glucose).

- Operate in batch mode until mid-exponential phase.

- Switch to continuous mode at a defined dilution rate (D, e.g., 0.1 h⁻¹).

- Monitor optical density (OD), off-gas (O2/CO2), and media composition until steady state is achieved (≥5 volume changes, constant OD & metabolites).

- At steady state, collect triplicate samples for OD, dry cell weight (DCW), and extracellular metabolomics (HPLC).

- Calculation: Uptake/Secretion Rate = D * (Cfeed - Cbroth) / X, where C is concentration and X is biomass (gDCW/L).

Protocol 3.2: Determination of Cellular Maintenance Requirements (ATP) Objective: Quantify the ATP expenditure required for cellular processes not directly correlated with growth. Materials: Microcalorimeter, chemostat culture, ATP assay kit. Procedure:

- Grow cells in carbon-limited chemostats at multiple dilution rates (D).

- Measure the steady-state heat output (J/s) using microcalorimetry, which correlates with total metabolic activity.

- Plot specific heat output rate (mW/gDCW) versus specific growth rate (μ = D).

- The y-intercept of the linear regression represents the heat output (and thus energy expenditure) at zero growth, which can be converted to an ATP flux using a suitable enthalpy-to-ATP conversion factor (NGAM).

- Validate by directly measuring ATP turnover using a radioactive 32P-labeling assay or by fitting the NGAM value during FBA model validation across multiple growth rates.

4. Mandatory Visualization

Title: Workflow for Integrating Constraints into FBA

Title: Key Flux Constraints in a Model

5. The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Constraint Determination

| Item / Reagent | Function in Protocol | Example/Supplier |

|---|---|---|

| Defined Minimal Media Kit | Provides reproducible, chemically defined growth medium for precise control of nutrient constraints. | M9 salts, MOPS EZ Rich defined medium kits (Teknova). |

| BioProcess Analyzer | Real-time monitoring of key metabolites (glucose, lactate, etc.) in bioreactor broth. | Cedex Bio HT (Roche), BioProfile FLEX2 (Nova Biomedical). |

| Off-Gas Analyzer | Measures O2 consumption and CO2 evolution rates for stoichiometric calculations. | Prima PRO Process Mass Spectrometer (Thermo Fisher). |

| Microcalorimeter | Directly measures metabolic heat flow for determining maintenance energy requirements. | TAM IV Isothermal Calorimeter (TA Instruments). |

| ATP Bioluminescence Assay Kit | Quantifies cellular ATP levels and turnover rates. | CellTiter-Glo (Promega). |

| 13C-Labeled Substrate | Enables experimental flux determination via 13C Metabolic Flux Analysis (MFA) for model validation. | [1-13C]Glucose, [U-13C]Glucose (Cambridge Isotope Labs). |

| Proteomics Sample Prep Kit | For digesting and preparing protein samples to quantify enzyme abundance constraints. | PreOmics iST kits, Filter-Aided Sample Preparation (FASP) kits. |

Within the broader FBA protocol for strain design, Step 3 involves performing computational simulations to predict metabolic behavior under defined conditions and analyzing the resulting flux distributions to identify engineering targets. This phase transforms a static metabolic model into a dynamic, predictive tool.

Application Notes

Flux Balance Analysis (FBA) simulations solve a linear programming problem to predict steady-state reaction fluxes that maximize or minimize a defined objective function (e.g., biomass, target metabolite production). Analyzing the resultant flux distribution reveals network bottlenecks, redundancy, and critical pathways. Key analyses include:

- Flexibility Analysis (FVA): Determines the minimum and maximum possible flux through each reaction while maintaining optimal objective function value, identifying rigid and flexible network points.

- FlacQ- Reaction Essentiality: Systematically knocks out reactions to simulate gene deletions and assess their impact on cellular objectives.

- Shadow Price Analysis: Interprets the sensitivity of the objective function to changes in metabolite availability, highlighting limiting nutrients.

The quantitative output from these simulations guides the selection of gene knockouts, knockdowns, or overexpression strategies in the subsequent strain design phase.

Experimental Protocol: Running FBA Simulations and Flux Variability Analysis

This protocol details the core computational workflow using the COBRA (Constraints-Based Reconstruction and Analysis) Toolbox in a MATLAB/Python environment.

Materials & Software:

- A validated genome-scale metabolic model (SBML format).

- MATLAB with the COBRA Toolbox v3.0+ or Python with cobrapy and matplotlib packages installed.

- A linear programming solver (e.g., GLPK, IBM CPLEX, Gurobi).

Procedure:

Model Import and Preparation:

- Load the metabolic model into the workspace (

readCbModelin MATLAB;cobra.io.read_sbml_modelin Python). - Define the simulation medium by setting the lower bounds of exchange reactions for available nutrients (e.g., glucose, oxygen) and secreted by-products.

- Load the metabolic model into the workspace (

Define Simulation Parameters:

- Set the objective function. For growth maximization, typically the biomass reaction is used.

- Specify optimization sense (

maximizeorminimize).

Run Steady-State FBA:

- Execute FBA (

optimizeCbModelin MATLAB;model.optimize()in Python). - Extract and save the optimal flux value for the objective and the complete flux vector for all reactions.

- Execute FBA (

Perform Flux Variability Analysis (FVA):

- Set the fraction of the optimal objective to be maintained (e.g., 99% of maximum growth). This parameter defines the solution space.

- Run FVA (

fluxVariabilityin MATLAB;cobra.flux_analysis.flux_variability_analysisin Python) to calculate the minimum and maximum possible flux for each reaction within the defined solution space.

Analyze and Visualize Results:

- Identify reactions with zero flux in the optimal solution (inactive).

- From FVA, pinpoint reactions with tightly constrained fluxes (small difference between min and max), indicating potential choke points.

- Visualize high-flux pathways on a metabolic map using visualization tools (e.g., Escher maps).

Expected Output & Interpretation: The primary output is a table of reaction fluxes. Reactions carrying high flux in the desired product synthesis pathway but low or variable flux in competing pathways become prime overexpression or knockout targets, respectively.

Data Presentation

Table 1: Example Flux Distribution for E. coli Central Metabolism under Growth Maximization

| Reaction ID | Reaction Name | Subsystem | Flux (mmol/gDW/h) | Min Flux (FVA) | Max Flux (FVA) |

|---|---|---|---|---|---|

| PGI | Glucose-6-phosphate isomerase | Glycolysis | 8.5 | 8.5 | 8.5 |

| PFK | Phosphofructokinase | Glycolysis | 8.5 | 8.1 | 10.2 |

| G6PDH2r | Glucose-6-phosphate dehydrogenase | Pentose Phosphate | 0.0 | 0.0 | 2.1 |

| PPC | Phosphoenolpyruvate carboxylase | TCA Anaplerosis | 1.2 | 0.0 | 3.8 |

| ACONTa | Aconitase (Aconitate -> Isocitrate) | TCA Cycle | 6.1 | 5.9 | 6.3 |

| BIOMASSEciML1515 | Biomass Reaction | Biomass Formation | 0.7 | 0.7 | 0.7 |

Table 2: Key Research Reagent Solutions

| Item | Function in FBA Workflow |

|---|---|

| Genome-Scale Metabolic Model (SBML File) | A structured, machine-readable representation of all known metabolic reactions, genes, and constraints for the target organism. The core input for simulations. |

| COBRA Toolbox / cobrapy | The standard software suite providing functions to load, modify, constrain, simulate, and analyze constraint-based metabolic models. |

| Linear Programming Solver (e.g., CPLEX) | The computational engine that performs the numerical optimization to find a flux distribution that satisfies all constraints and optimizes the objective. |

| Chemical Media Formulation (in silico) | Defines the upper/lower bounds of exchange reactions in the model, simulating the organism's nutritional environment (e.g., minimal glucose medium). |

| Visualization Software (e.g., Escher) | Generates interactive, web-based metabolic maps to overlay simulation flux data, enabling intuitive interpretation of pathway usage. |

Visualizations

Title: FBA Simulation and Flux Analysis Workflow

Title: Example Flux Distribution in Central Carbon Metabolism

This step follows the completion of a validated Genome-Scale Metabolic Model (GSM) and the application of Flux Balance Analysis (FBA) to predict wild-type flux distributions. Within the broader thesis protocol, Step 4 is the critical transition from in silico analysis to actionable strain design. It leverages FBA-derived predictions to systematically identify genetic modifications that will re-route metabolic flux toward the target product (e.g., a biofuel, pharmaceutical precursor, or commodity chemical). The primary strategies are gene/protein knockout (KO), overexpression (OE), and downregulation (DR).

Computational Target Identification: Algorithms and Data Interpretation

2.1. Core Algorithms and Their Applications Target identification uses Constraint-Based Reconstruction and Analysis (COBRA) methods. Key algorithms include:

- OptKnock: Identifies gene knockout strategies for coupled growth and product formation. It performs a bi-level optimization: inner problem maximizes biomass, outer problem maximizes product formation.

- RobustKnock / OptForce: Identifies not only knockouts but also required flux changes (upward/downward). OptForce compares wild-type and desired phenotype flux distributions to pinpoint must overexpress and must downregulate reactions.

- Minimization of Metabolic Adjustment (MOMA): Predicts flux distribution after a knockout by minimizing the Euclidean distance from the wild-type flux distribution. Useful for predicting adaptive responses.

- Regulatory on/off minimization (ROOM): Similar to MOMA but uses a mixed-integer linear programming approach to minimize significant flux changes.

2.2. Quantitative Output and Decision Table Computational simulations yield quantitative metrics for candidate targets. Results should be summarized as follows:

Table 1: Example Output from OptKnock and OptForce Simulations for Succinate Overproduction in E. coli

| Target Gene | Associated Reaction | Modification Type | Predicted Succinate Yield (mol/mol Glc) | Predicted Growth Rate (h⁻¹) | Algorithm Used | Rationale |

|---|---|---|---|---|---|---|

| ldhA | Lactate dehydrogenase | Knockout | 0.65 | 0.38 | OptKnock | Eliminates lactate byproduct, redirects flux to pyruvate. |

| pflB | Pyruvate formate-lyase | Knockout | 0.71 | 0.35 | OptKnock | Eliminates formate/acetate byproducts. |

| ppc | Phosphoenolpyruvate carboxylase | Overexpression | 0.85 | 0.41 | OptForce | Increases anaplerotic flux into TCA cycle. |

| pckA | Phosphoenolpyruvate carboxykinase | Downregulation | 0.78 | 0.39 | OptForce | Prevents gluconeogenic drain of OAA. |

| ptsG | Glucose PTS transporter | Attenuation | 0.70 | 0.32 | Manual Curation | Reduces glucose uptake rate to lower glycolytic overflow. |

2.3. Protocol: Running OptKnock using Python COBRApy

Experimental Implementation Protocols

3.1. Protocol for Implementing Knockouts (CRISPR-Cas9)

- Objective: Create a clean, markerless gene deletion in a bacterial host.

- Materials: pCRISPR plasmid (Cas9 + gRNA scaffold), pTarget plasmid (contains homology repair template with 500bp upstream/downstream of target gene, with an in-frame deletion), electrocompetent cells, SOC medium, selective agar plates (e.g., Kanamycin for pCRISPR, Spectinomycin for pTarget).

- Steps:

- Design two 20-nt guide RNA sequences targeting the non-template strand of the gene's 5' region using software like CHOPCHOP.

- Synthesize oligos, anneal, and clone into the pCRISPR plasmid's BsaI site.

- Clone the homology repair template (PCR-amplified from genomic DNA) into pTarget.

- Co-transform both plasmids into the host strain via electroporation.

- Recover cells in SOC medium for 1 hour, then plate on double-antibiotic plates. Incubate at 30°C (temperature-sensitive origin on pCRISPR).

- Screen colonies via colony PCR using primers flanking the deletion site.

- Cure the plasmids by growing positive colonies at 37°C without antibiotics. Verify loss of plasmids and genotype stability.

3.2. Protocol for Implementing Overexpression (Inducible System)

- Objective: Achieve controlled, high-level expression of a target gene.

- Materials: Plasmid with strong, inducible promoter (e.g., pTrc99a with trc promoter, IPTG-inducible), gene of interest (GOI) codon-optimized for host, DNA assembly mix (e.g., Gibson Assembly), competent cells, induction agent (IPTG).

- Steps:

- Amplify the GOI with primers containing 20-30bp overlaps matching the linearized plasmid backbone.

- Perform Gibson Assembly of the GOI and linearized plasmid. Incubate at 50°C for 1 hour.

- Transform assembly mix into competent cells, plate on selective media.

- Screen colonies by colony PCR and sequence-validate the construct.

- Inoculate a flask with the engineered strain and grow to mid-exponential phase (OD600 ~0.5-0.6).

- Induce expression with optimized concentration of IPTG (e.g., 0.1 - 1.0 mM).

- Monitor growth and product titer over time to determine optimal induction point and duration.

Visualization: The Strain Design Workflow

Title: Strain Design Target Identification and Implementation Workflow

The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Research Reagents for Genetic Modifications

| Reagent / Material | Function in Metabolic Engineering | Example Product / Kit |

|---|---|---|

| CRISPR-Cas9 Plasmid System | Enables precise, markerless gene knockouts and integrations. | pCas9/pTargetF system for E. coli; Addgene Kit #62655. |

| Gibson Assembly Master Mix | One-step, isothermal assembly of multiple DNA fragments for plasmid construction. | NEBuilder HiFi DNA Assembly Master Mix (NEB). |

| Inducible Expression Plasmid | Provides controlled, high-level expression of target genes. | pET series (T7/lacO, IPTG); pTrc99a (trc/lacO). |

| CRISPRi sgRNA Plasmid Library | For programmable transcriptional downregulation (knock-down) of genes. | dCas9 + sgRNA cloning vector (e.g., pdCas9-bacteria). |

| Site-Directed Mutagenesis Kit | Introduces point mutations in promoters for fine-tuning expression (downregulation). | Q5 Site-Directed Mutagenesis Kit (NEB). |

| Antibiotics for Selection | Maintains selection pressure for plasmids and genomic modifications. | Kanamycin, Ampicillin, Chloramphenicol, Spectinomycin. |

| DNA Polymerase for Colony PCR | Rapid screening of clones directly from bacterial colonies. | OneTaq Quick-Load 2X Master Mix (NEB). |

| Automated DNA Sequencer | Verification of plasmid constructs and genomic modifications. | MiSeq System (Illumina) for NGS; Sanger services. |

This application note is framed within the broader context of a thesis on the systematic application of Flux Balance Analysis (FBA) protocols for rational strain design in metabolic engineering. The thesis posits that an integrated, iterative workflow combining in silico modeling, targeted genetic interventions, and physiological validation is essential for efficient microbial cell factory development. This case study on succinate-overproducing Escherichia coli serves as a prime exemplar of this protocol, demonstrating how FBA-driven predictions guide the rewiring of central carbon metabolism to convert a glycolytic organism into an efficient succinate producer.

Background and Key Metabolic Pathways

Succinate, a C4-dicarboxylic acid, is a valuable platform chemical with applications in polymers, food, pharmaceuticals, and green solvents. Native E. coli produces minimal succinate under aerobic conditions, primarily directing carbon flux toward biomass and acetate. The objective is to redesign metabolism to maximize the theoretical yield from glucose, which is 1.12 mol succinate / mol glucose under anaerobic conditions and 1.71 mol/mol under fully oxidative conditions.

Key pathways for succinate production in engineered E. coli include:

- Glyoxylate Shunt: Bypasses the decarboxylation steps of the TCA cycle, conserving carbon.

- Reductive (Anaerobic) Branch of the TCA Cycle: Uses phosphoenolpyruvate (PEP) carboxylase or pyruvate carboxylase for CO₂ fixation.

- Oxidative TCA Cycle: Can be optimized under microaerobic conditions.

- Cofactor Engineering: Balancing NADH/NAD⁺ and ATP levels is critical for driving reductive flux.

FBA of the E. coli genome-scale model (e.g., iJO1366) identifies gene knockout targets that force flux through these desired pathways.

Table 1: Key Gene Deletion Targets for Succinate Overproduction

| Target Gene | Protein / Function | Physiological Consequence | Rationale for Deletion |

|---|---|---|---|

| ldhA | Lactate dehydrogenase | Eliminates lactate fermentation | Diverts pyruvate toward oxaloacetate (OAA) via PC or PEP via PPC. |

| adhE | Alcohol dehydrogenase | Eliminates ethanol production | Conserves carbon and reduces reducing equivalent (NADH) consumption. |

| ackA-pta | Acetate kinase & phosphate acetyltransferase | Eliminates acetate production | Increases acetyl-CoA availability for the glyoxylate shunt; removes major byproduct. |

| poxB | Pyruvate oxidase | Eliminates acetate production from pyruvate | Further reduces acetate formation. |

| frdABCD | Fumarate reductase | Blocks succinate consumption | Essential under anaerobic conditions to prevent succinate re-oxidation to fumarate. |

| sdhABCD | Succinate dehydrogenase | Blocks succinate oxidation | Essential under aerobic/microaerobic conditions to prevent TCA cycle reversal. |

| mgSA | Methylglyoxal synthase | Blocks methylglyoxal pathway | Alleviates metabolic stress from diacetyl accumulation. |

Table 2: Key Gene Overexpression Targets for Succinate Overproduction

| Target Gene / Pathway | Protein / Function | Rationale for Overexpression | Typical Vector/Promoter |

|---|---|---|---|

| pyc (from R. etli) | Pyruvate carboxylase | Anaplerotic CO₂ fixation from pyruvate to OAA. | pTrc99a, Ptac |

| ppc (E. coli) | PEP carboxylase | Anaplerotic CO₂ fixation from PEP to OAA. Strong flux driver. | pCL1920, PglnA |

| glyoxylate shunt ( aceBAK) | Isocitrate lyase, Malate synthase | Provides a carbon-conserving route from acetyl-CoA to succinate. | pBBR1MCS-2, Ptrc |

| macB or maeB | Malic enzyme (NADP⁺/NAD⁺) | Converts malate to pyruvate, potentially cycling carbon and generating NADPH. | pETDuet-1, PT7 |

Table 3: Performance Summary of Engineered Strains (Representative Literature Data)

| Engineered Strain Genotype | Cultivation Mode | Substrate | Titer (g/L) | Yield (g/g glucose) | Productivity (g/L/h) | Reference Year |

|---|---|---|---|---|---|---|

| AFP111 (ΔldhA ΔadhE ΔackA) | Dual-phase (Aer -> Anaer) | Glucose | 69.2 | 0.87 | 1.30 | 2006 |

| HL27659k (ΔsdhAB ΔiclR ΔackA ΔldhA ΔadhE ΔfocA-pflB) | Anaerobic | Glucose | 76.6 | 1.10 | 1.10 | 2013 |

| SA105 (ΔldhA ΔadhE ΔackA ΔptsG, pyc overexpression) | Microaerobic | Glucose | 58.3 | 0.92 | 0.97 | 2014 |

| DBS (ΔsdhAB ΔiclR ΔsucCD, ppc overexpression) | Aerobic | Glucose | 25.6 | 0.38 | 0.53 | 2021 |

| XYZ (Multi-omic guided design) | Fed-batch | Sugar mix | 110.5 | 0.95 | 2.10 | 2023 |

Protocols and Methodologies

Protocol 4.1:In SilicoStrain Design Using FBA

Objective: To predict gene knockout and overexpression targets that maximize succinate production flux using a genome-scale metabolic model (GEM).

Materials:

- Software: COBRA Toolbox (MATLAB), Python (cobrapy), or similar.

- Model: E. coli GEM (e.g., iJO1366, iML1515).

- Constraints: Glucose uptake = 10 mmol/gDW/h; O₂ uptake as per condition; ATP maintenance (ATPM) = 8.39 mmol/gDW/h.

Method:

- Load Model: Import the GEM (SBML format) into the analysis environment.

- Set Constraints: Define the environmental and physiological constraints (carbon source, oxygen, growth rate).

- Define Objective: Initially set biomass reaction as the objective function and perform FBA to establish wild-type flux distribution.

- Simulate Gene Deletions: Use algorithms like OptKnock (bi-level optimization: maximize product flux while allowing maximal biomass) or Minimal Cut Sets (MCS) to identify gene/reaction knockout combinations that couple succinate production to growth.

- Simulate Gene Overexpression: Use FBA with flux variability analysis (FVA) to identify reactions where increased flux capacity would benefit succinate yield. Alternatively, use OptForce to identify must-overexpress and must-suppress reactions.

- Validate Predictions: Compare in silico predicted yields and essentiality with literature data. Generate a ranked list of genetic targets.

Protocol 4.2: Construction of anE. coliSuccinate Production Strain via λ-Red Recombineering

Objective: To sequentially introduce gene deletions (e.g., ldhA, adhE, ackA-pta) into the E. coli chromosome.

Materials:

- Strains: E. coli MG1655 (wild-type), E. coli with pKD46 plasmid (or similar, expresses λ-Red recombinase).

- Oligonucleotides: 70-mer primers with 50-nt homology to the target gene flanking regions and 20-nt homology to the FRKanamycin resistance (Frt-flanked kanR) cassette from pKD13.

- PCR Reagents: High-fidelity polymerase.

- Media: LB + Ampicillin (100 µg/mL) for pKD46 maintenance; LB + Kanamycin (50 µg/mL) for selection of recombinants.

- Inducer: L-Arabinose (1% w/v stock).

Method:

- Prepare Electrocompetent Cells: Grow E. coli harboring pKD46 at 30°C to mid-log phase (OD600 ~0.4-0.6). Induce λ-Red genes with 10 mM L-arabinose for 1 hour. Wash cells 3x with ice-cold 10% glycerol.

- Amplify Resistance Cassette: PCR amplify the kanR cassette from pKD13 using target-specific primers.

- Electroporation: Mix ~100 ng of purified PCR product with 50 µL of electrocompetent cells. Electroporate (1.8 kV, 5 ms). Immediately recover in 1 mL SOC at 37°C for 2 hours.

- Selection: Plate on LB agar with Kanamycin. Incubate at 37°C (pKD46 is temperature-sensitive and will be lost).

- Verification: Verify deletion via colony PCR using verification primers binding outside the homologous region.

- Cassette Removal: Transform verified colony with pCP20 (expresses FLP recombinase). Heat-shock at 42°C to induce FLP, removing the kanR cassette, leaving a single FRT "scar" site.

- Iterate: Repeat steps 1-6 for subsequent deletions, using appropriate antibiotic markers (or recycling Kanamycin after FLP).

Protocol 4.3: Anaerobic/Microaerobic Fed-Batch Fermentation for Succinate

Objective: To evaluate the performance of the engineered strain in a controlled bioreactor.

Materials:

- Bioreactor: 5-L fermenter with pH, DO, temperature control.

- Medium: Defined mineral salts medium (e.g., M9 or similar) with glucose as carbon source.

- Base: 5M NaOH for pH control (maintained at 6.8-7.0).

- Antifoam: Polypropylene glycol.

- Gas: N₂/CO₂ mixture for anaerobic sparging; air for microaerobic conditions.

- Analytics: HPLC for organic acids (succinate, acetate, lactate, formate), glucose.

Method:

- Inoculum Preparation: Grow engineered strain overnight in LB. Subculture into seed medium with glucose. Grow to late exponential phase.

- Bioreactor Setup: Sterilize the vessel with initial batch medium (e.g., 20 g/L glucose). Set temperature to 37°C, pH to 7.0.

- Inoculation: Inoculate at an initial OD600 of ~0.1.

- Anaerobic Induction: After initial aerobic growth to OD600 ~2-3, purge the headspace and medium with N₂/CO₂ (e.g., 80/20) to establish anaerobic conditions. Set agitation to low speed (e.g., 50-100 rpm).

- Fed-Batch Operation: Once batch glucose is depleted, initiate a fed-batch phase with a concentrated glucose feed (e.g., 500 g/L) at an exponential or constant rate to maintain a low residual sugar concentration (<5 g/L).

- Monitoring: Record OD600, pH, DO, base consumption. Take samples hourly/bihourly for HPLC analysis.

- Harvest: Terminate fermentation when productivity declines significantly or maximum working volume is reached.

- Analysis: Calculate titer (g/L), yield (g succinate / g glucose consumed), volumetric productivity (g/L/h), and specific productivity (g/gDW/h).

Visualizations

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Strain Design and Fermentation

| Item / Reagent | Function / Application | Example Product / Specification |

|---|---|---|

| Genome-Scale Metabolic Model (GEM) | In silico flux prediction and target identification. | E. coli iJO1366 or iML1515 (from BiGG Models). |

| COBRA Toolbox | MATLAB suite for constraint-based modeling and analysis (FBA, OptKnock). | https://opencobra.github.io/cobratoolbox/ |

| λ-Red Recombineering System | Enables efficient, PCR-based chromosomal gene deletions/insertions in E. coli. | Plasmid set: pKD46 (Red genes), pKD13 (template), pCP20 (FLP). |

| High-Fidelity DNA Polymerase | Accurate amplification of linear DNA fragments for recombineering. | Phusion or Q5 DNA Polymerase. |

| Defined Mineral Salts Medium | Provides controlled, reproducible environment for fermentation studies. | M9 minimal medium or MOPS-based defined medium. |

| Anaerobic Chamber or Gas Pak | Creates an oxygen-free environment for plates and cultures. | Coy Laboratory Products or BD GasPak EZ. |

| Bioreactor with pH & DO Control | Enables precise control of environmental parameters during fed-batch fermentation. | Eppendorf BioFlo, Sartorius Biostat, or Applikon Biotechnology systems. |

| HPLC with RI/UV Detector | Quantification of organic acids (succinate, acetate) and sugars in fermentation broth. | Aminex HPX-87H column (Bio-Rad), 5 mM H₂SO₄ mobile phase. |

| CRISPR-Cas9 Kit for E. coli | For rapid, multiplexed genome editing (alternative to λ-Red). | Commercial kits (e.g., from ATUM or NEB) or plasmid sets (pTarget/pCas). |

| RNA-Seq Kit | Transcriptomic analysis to validate metabolic shifts and identify unintended changes. | Illumina-compatible kits (e.g., NEBNext Ultra II). |

Beyond the Simulation: Troubleshooting Common FBA Pitfalls and Refining Predictions

Addressing Model Gaps and Inaccuracies in Metabolic Reconstructions

Metabolic reconstructions are pivotal for constraint-based modeling techniques like Flux Balance Analysis (FBA), used in metabolic engineering for strain design. Inaccuracies—from missing reactions, incorrect gene-protein-reaction (GPR) rules, or erroneous thermodynamic constraints—compromise predictive power. This protocol details integrated computational and experimental methods to identify and rectify these gaps, enhancing model fidelity for robust in silico strain design.

Key Gaps, Detection Methods, and Validation Protocols

Table 1: Common Model Inconsistencies & Quantitative Detection Metrics

| Gap/Inaccuracy Type | Primary Detection Method | Typical Prevalence in Draft Models* | Key Quantitative Metric for Prioritization |

|---|---|---|---|

| Missing Reactions (Gaps) | Flux Consistency Analysis (FVA) | 15-25% of metabolites may be dead-end | Number of blocked metabolites |

| Incorrect Stoichiometry | Reaction Thermodynamics (ΔG'°) | ~5-10% of reactions may be unbalanced | Energy Balance Discrepancy Score |

| Erroneous GPR Rules | OMICS Data Integration (RNA-seq) | Discrepancy in ~10-15% of GPRs | Correlation between gene expression and predicted flux (ρ) |

| Missing Transport/Exchange Reactions | Growth Medium Simulation | Highly organism/medium dependent | Number of essential nutrients failing to support growth |

| Incorrect Biomass Composition | Literature Curation & Experiments | Varies significantly | Impact on predicted vs. experimental growth yield (Yx/s) |

Prevalence estimates based on recent literature for microbial models like *E. coli and S. cerevisiae.

Detailed Experimental Protocols

Protocol 1: Gap-Filling via Growth Phenotype Data

Objective: Identify and add missing reactions required to simulate observed growth on defined media. Materials:

- Reconstituted metabolic model (SBML format)

- Chemically defined growth medium composition

- High-quality genome annotation for the target organism

- Software: COBRA Toolbox (v3.0+), MATLAB or Python.

Procedure:

- Model Constraint: Set exchange reaction bounds to reflect the provided defined medium. Allow uptake only for provided carbon, nitrogen, phosphorus, sulfur sources, and essential ions.

- Simulation: Perform FBA maximizing biomass reaction. A zero flux indicates a gap.

- Candidate Reaction Generation: Use a universal biochemical database (e.g., MetaCyc, KEGG) to generate a list of reactions that could fill the gap, prioritizing reactions with genomic evidence (e.g., homology to annotated genes).

- Iterative Testing: Add candidate reactions to the model individually or in small sets. Re-run FBA. Accept reactions that enable growth while being consistent with network stoichiometry.

- Curation: Manually verify added reactions for chemical and taxonomic plausibility. Update GPR rules accordingly.

- Experimental Validation: Design knockout strain of the added gene. The knockout should exhibit the predicted auxotrophy on the defined medium.

Protocol 2: Correcting GPR Rules Using Transcriptomic Data

Objective: Refine Boolean GPR associations using gene expression evidence. Materials:

- Model with GPR rules.

- RNA-seq data (TPM/RPKM counts) from relevant growth conditions.